Porous doped titanium-based lithium adsorbent and preparation method thereof

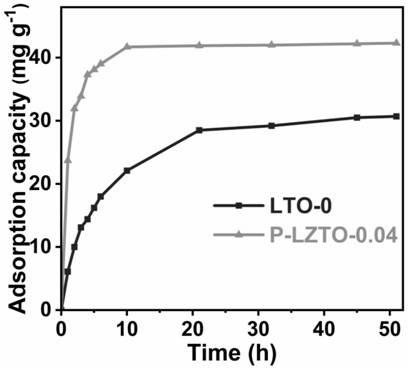

A technology of lithium adsorption and titanium series, which is applied in the field of positive electrode material preparation, can solve the problems of slow adsorption and desorption rate, influence on practical application, and low efficiency of industrial lithium recovery, and achieve the effect of simple and convenient operation, reduced cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

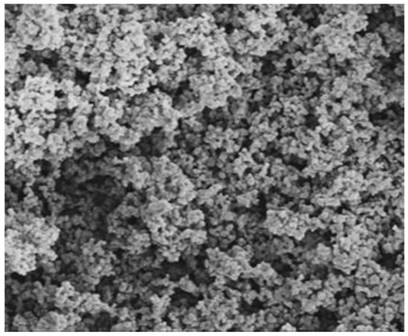

Image

Examples

Embodiment 1

[0050] In this example, the porous doped titanium-based lithium adsorbent was prepared by the following steps:

[0051] (1) Take the M salt and lithium source press with a molar ratio of 1:0.04, add it to absolute ethanol and grind to form a suspension; wherein M n+ for Zn 2+ , the M salt is zinc acetate, and the lithium source is lithium acetate;

[0052] 2) Put the suspension obtained in step (1) into an oven and heat at 60°C for 0.5h to obtain a mixture of molten lithium acetate and zinc acetate;

[0053] 3) in step (2) gained molten state liquid press titanium source mole fraction and M n+ The sum of mole fractions is 1 and the mass ratio of nitrogen-containing surfactant and lithium source: 1:0.4 Add metatitanic acid (hydrated titanium dioxide) and nitrogen-containing surfactant, grind evenly and then dry, the nitrogen-containing surfactant is Dodecyltrimethylammonium bromide;

[0054] 4) Sintering at a temperature of 700° C. for 4 hours in an air environment to obtai...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, except that in step 1, the molar ratio of the M salt to the lithium source is different, and the rest are the same settings.

[0058] In this example, the porous doped titanium-based lithium adsorbent was prepared by the following steps:

[0059] (1) Take the M salt and lithium source press with a molar ratio of 1:0.02, add it to absolute ethanol and grind to form a suspension, the M n+ for Zn 2+ , the M salt is zinc acetate, and the lithium source is lithium acetate;

[0060] (2) Put the suspension obtained in step (1) into an oven and heat at 60°C for 0.5h to obtain a mixture of molten lithium acetate and zinc acetate;

[0061] (3) in step (2) gained molten state liquid press titanium source molar fraction and M n+ The sum of mole fractions is 1 and the mass ratio of nitrogen-containing surfactant and lithium source is 1:0.4. Add metatitanic acid (hydrated titanium dioxide) and nitrogen-containing surfactant, g...

Embodiment 3

[0065] This embodiment is basically the same as Embodiment 1, except that in step 1, the molar ratio of the M salt to the lithium source is different, and the rest are the same settings.

[0066] In this example, the porous doped titanium-based lithium adsorbent was prepared by the following steps:

[0067] (1) Take the M salt and lithium source press with a molar ratio of 1:0.1, add it to absolute ethanol and grind to form a suspension, the M n+ for Zn 2+ , the M salt is zinc acetate, and the lithium source is lithium acetate;

[0068] (2) Put the suspension obtained in step (1) into an oven and heat at 60°C for 0.5h to obtain a mixture of molten lithium acetate and zinc acetate;

[0069] (3) in step (2) gained molten state liquid press titanium source molar fraction and M n+ The sum of mole fractions is 1 and the mass ratio of nitrogen-containing surfactant and lithium source is 1:0.4. Add metatitanic acid (hydrated titanium dioxide) and nitrogen-containing surfactant, gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com