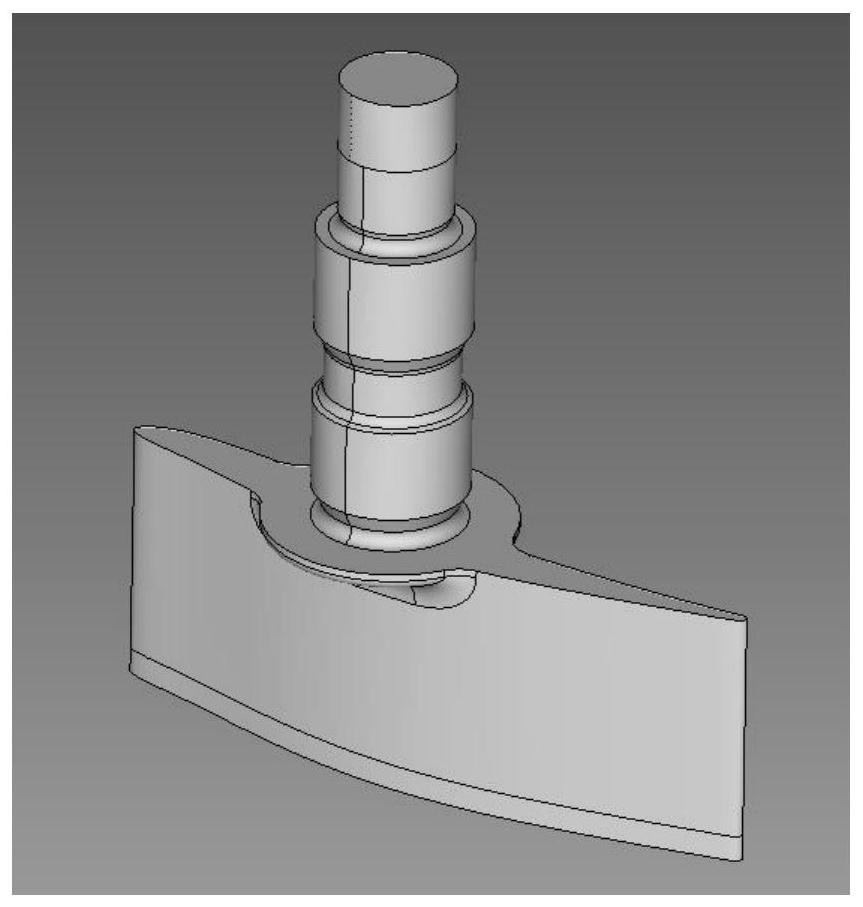

A kind of nickel-based alloy material of supercharger nozzle ring blade resistant to 1050 ℃ and its manufacturing method

A nickel-based alloy and nozzle ring technology, applied in the field of alloy metals, can solve the problems that iron-based materials cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

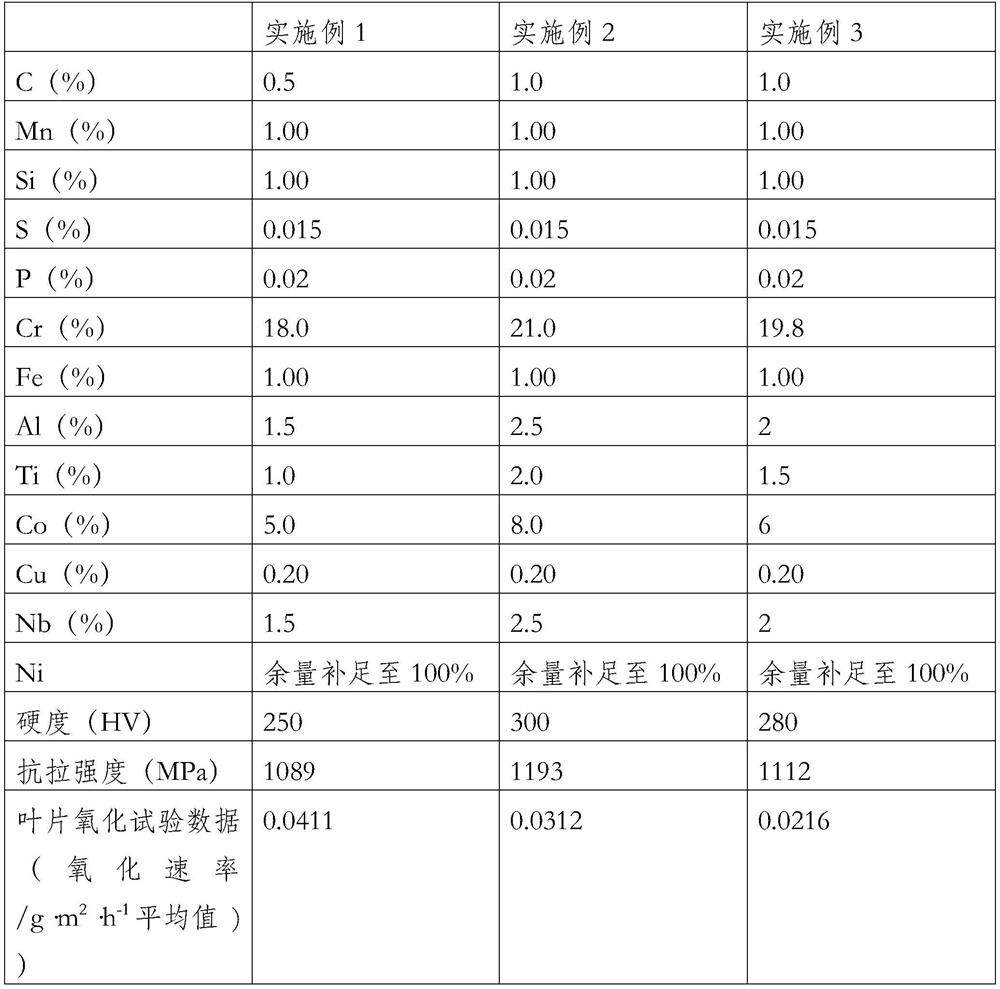

[0033] This embodiment provides a nickel-based alloy material for a turbocharger nozzle ring vane resistant to 1050°C and its manufacturing method:

[0034] (1) Nickel-based alloy materials for turbocharger nozzle ring blades resistant to 1050 °C: including elements C, Mn, Si, S, P, Cr, Fe, Al, Ti, Co, Cu, Nb and Ni; The mass is expressed as a percentage, based on the mass of the blade nickel-based alloy material as a percentage, the C content is 0.5%, the Mn content is 1.00%, the Si content is 1.00%, and the S content is 0.015% %, the P content is 0.02%, the Cr content is 18.0%, the Fe content is 1.00%, the Al content is 1.5%, the Ti content is 1.0%, and the Co content is 5.0%, The Cu content is 0.20%, the Nb content is 1.5%, and the balance is Ni.

[0035] (2) Nickel-based alloy material for turbocharger nozzle ring blades resistant to 1050°C and its manufacturing method: MIM process is adopted, the sintering temperature is 1240°C, and the sintering atmosphere is argon; wit...

Embodiment 2

[0037] This embodiment provides a nickel-based alloy material for a turbocharger nozzle ring vane resistant to 1050°C and its manufacturing method:

[0038] (1) Nickel-based alloy materials for turbocharger nozzle ring blades resistant to 1050 °C: including elements C, Mn, Si, S, P, Cr, Fe, Al, Ti, Co, Cu, Nb and Ni; The mass is expressed as a percentage, based on the mass of the nickel-based alloy material of the blade as a percentage, the C content is 1.0%, the Mn content is 1.00%, the Si content is 1.00%, and the S content is 0.015% %, the P content is 0.02%, the Cr content is 21.0%, the Fe content is 1.00%, the Al content is 2.5%, the Ti content is 2.0%, and the Co content is 8.0%, The Cu content is 0.20%, the Nb content is 2.5%, and the balance is Ni.

[0039] (2) Nickel-based alloy material for turbocharger nozzle ring blades resistant to 1050°C and its manufacturing method: MIM process is adopted, the sintering temperature is 1240°C, and the sintering atmosphere is arg...

Embodiment 3

[0041] This embodiment provides a nickel-based alloy material for a turbocharger nozzle ring vane resistant to 1050°C and its manufacturing method:

[0042] (1) Nickel-based alloy materials for turbocharger nozzle ring blades resistant to 1050 °C: including elements C, Mn, Si, S, P, Cr, Fe, Al, Ti, Co, Cu, Nb and Ni; The mass is expressed as a percentage, based on the mass of the nickel-based alloy material of the blade as a percentage, the C content is 1.0%, the Mn content is 1.00%, the Si content is 1.00%, and the S content is 0.015% %, the P content is 0.02%, the Cr content is 19.8%, the Fe content is 1.00%, the Al content is 2%, the Ti content is 1.5%, and the Co content is 6%, The Cu content is 0.20%, the Nb content is 2%, and the balance is Ni.

[0043] (2) Nickel-based alloy material for turbocharger nozzle ring blades resistant to 1050°C and its manufacturing method: MIM process is adopted, the sintering temperature is 1240°C, and the sintering atmosphere is argon; wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com