Rapid cooling and quenching device for chain production

A rapid cooling and quenching device technology, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of multiple operations, low quenching quality, and low quenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

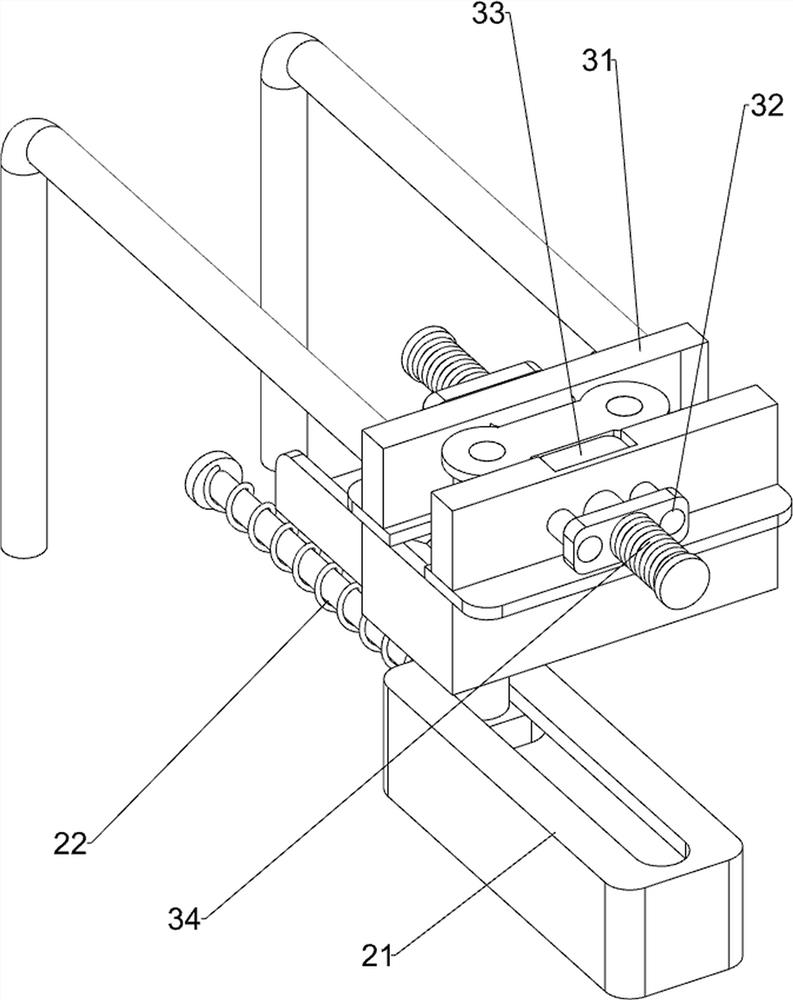

[0082] A rapid cooling and quenching device for chain production, such as figure 1 As shown, it includes a base 1, a sliding burning mechanism 2 and a bearing clamping mechanism 3. The sliding burning mechanism 2 is arranged in the upper middle of the base 1, and the bearing clamping mechanism 3 is arranged on the right side of the base 1.

[0083] When people want to quench the chain, they can use this kind of rapid cooling and quenching device for chain production. First, the user ignites the fire in the sliding burning mechanism 2, and then puts the chain into the load clamping mechanism 3 , the chain is quenched through the sliding burning mechanism 2 to realize the quenching effect of the chain. After the chain quenching is completed, the sliding burning mechanism 2 is extinguished.

Embodiment 2

[0085] On the basis of Example 1, such as figure 2 with image 3 As shown, the sliding burning material mechanism 2 includes a support frame 21 with a slide rail, a fixed slider 22, a stove 23, a first spring 24, a placement plate 25 and a water ski 26, and the upper middle part of the base 1 is provided with a slide rail. The support frame 21 is equipped with a sliding rail in the support frame 21, and a fixed slider 22 is arranged on the fixed slider 22. The first spring 24 is wound on the fixed slider 22. The left end of the first spring 24 is connected with the support frame 21 with a slide rail. The right end is connected with fixed slide block 22, and fixed slide block 22 tops are provided with water-skiing board 26, and water-skiing board 26 left walls are provided with burning stove 23, and burning stove 23 tops are provided with two placement plates 25.

[0086] The user puts the chain in the placement plate 25, puts the fuel into the burner 23, ignites it, and then...

Embodiment 3

[0090] On the basis of Example 2, such as Figure 4-Figure 10 As shown, also includes watering mechanism 4, and the left side on base 1 is provided with watering mechanism 4, and watering mechanism 4 includes water discharge frame 41, outlet pipe 42, first sliding sleeve 43, sliding switch plate 44 and the third Spring 45, the left side on the base 1 is provided with a water discharge frame 41, the water discharge frame 41 right wall is provided with a water outlet pipe 42, the water outlet pipe 42 is connected with the fixed frame 31, and the water discharge frame 41 left wall middle part is provided with the first sliding sleeve 43, the first The slide switch plate 44 is slidably arranged on the sliding sleeve 43, the slide switch plate 44 is connected with the base 1, the third spring 45 is wound on the slide switch plate 44, the top of the third spring 45 is connected with the slide switch plate 44, and the third spring The bottom end of 45 is connected with the first slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com