Methanol evaporation and oxidation device for formaldehyde production by silver method

A technology of oxidation device and methanol evaporator, which is applied in the separation/purification of carbonyl compounds, mixing methods, organic chemistry, etc., can solve the problems of poor mixing effect and achieve good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

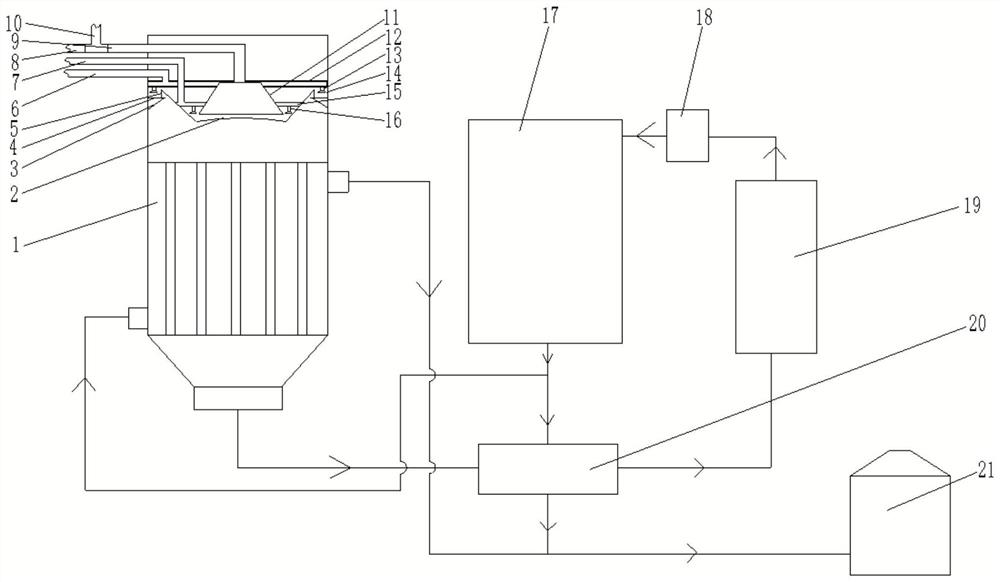

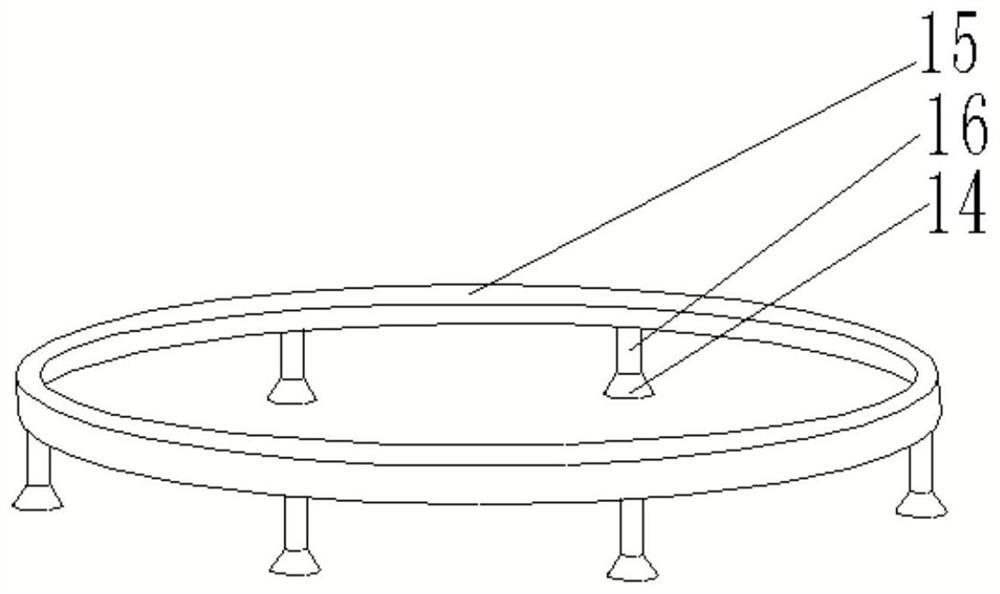

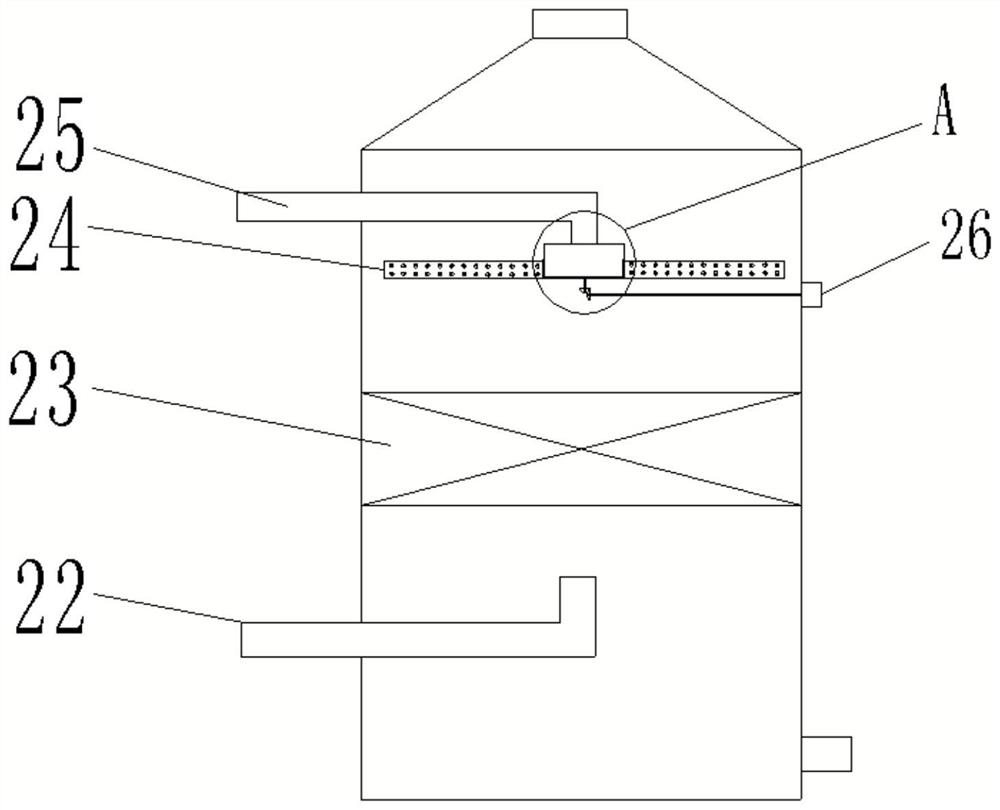

[0025] Such as Figure 1-5 As shown, a methanol evaporation and oxidation device for silver method formaldehyde production includes a methanol evaporator, and the methanol evaporator is fixedly connected with a gas feed pipe 9, a methanol feed pipe 7, a soft water feed pipe 6, and a gas feed pipe 9 The exhaust gas feed pipe 10 and the air feed pipe 8 are respectively connected through the tee; the gas feed pipe 9 extends to the methanol evaporator and is fixedly connected to the cover body 11. The cover body 11 is a frustum-shaped shell structure with an open lower end and a hollow interior. , the lower part of the cover body 11 is located in the gas flow direction adjustment member, and the gas flow direction adjustment member is fixed in the methanol evaporator through a fixing device, wherein the fixing device includes a frustum-shaped shell structure outer wall fixedly connected with the gas flow direction adjustment member The support rod 5, the lower end of the support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com