Compound emulsion stabilizer

A technology of emulsification stabilizer and potassium chloride, which is applied in the direction of dough/premix, baking, baking mixture, etc., and can solve the problems of quality decline and difficulty in uniform emulsification of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

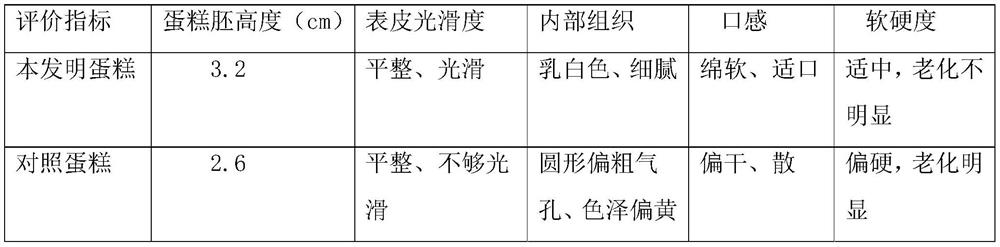

Embodiment 1

[0024] Example 1: The compound emulsion stabilizer is composed of the following raw materials in parts by mass: 2 parts of potassium chloride, 7 parts of gum arabic, 7 parts of propylene glycol alginate, and 20 parts of maltodextrin.

[0025] The preparation method of sponge cake for evaluation of the present invention:

[0026] Raw materials: egg liquid 600g, white sugar 300g, salt 1g, cake oil 20g, citric acid 2g, sorbitol liquid 30g, cake powder 300g, baking powder 3g, salad oil 100g, compound emulsification stabilizer 30g.

[0027] Process:

[0028] (1) Store all materials in a refrigerator at a temperature of 10° C., and use them after the temperature stabilizes.

[0029] (2) Preheat the oven to 180°C and 165°C for later use.

[0030] (3) Beat the eggs into a mixing bucket, add salt, citric acid, white sugar, sorbitol liquid, cake oil, and compound emulsification stabilizer, and beat with a mixer until it turns white and forms a thick foam.

[0031] (4) Sift the cake f...

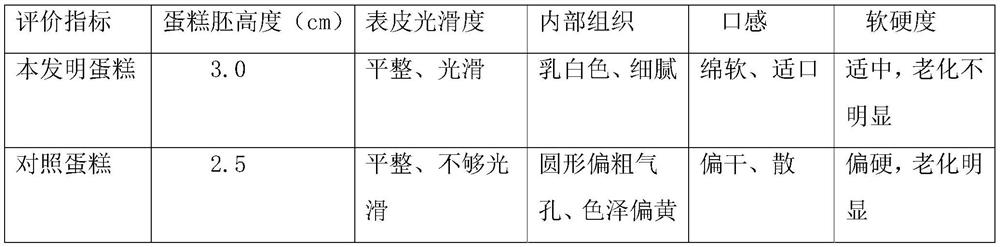

Embodiment 2

[0038] Example 2: The compounded emulsification stabilizer is composed of the following raw materials in parts by mass: 7 parts of potassium chloride, 3 parts of gum arabic, 3 parts of propylene glycol alginate, and 30 parts of maltodextrin.

[0039] The preparation method of sponge cake for evaluation of the present invention:

[0040]Raw materials: egg liquid 600g, white sugar 300g, salt 1g, cake oil 20g, citric acid 2g, sorbitol liquid 30g, cake powder 300g, baking powder 3g, salad oil 100g, compound emulsification stabilizer 35g.

[0041] Process:

[0042] (1) Store all materials in a refrigerator at a temperature of 5° C., and use them after the temperature stabilizes.

[0043] (2) Preheat the oven to 180°C and 165°C for later use.

[0044] (3) Beat the eggs into a mixing bucket, add salt, citric acid, white sugar, sorbitol liquid, cake oil, and compound emulsification stabilizer, and beat with a mixer until it turns white and forms a thick foam.

[0045] (4) Sift the ...

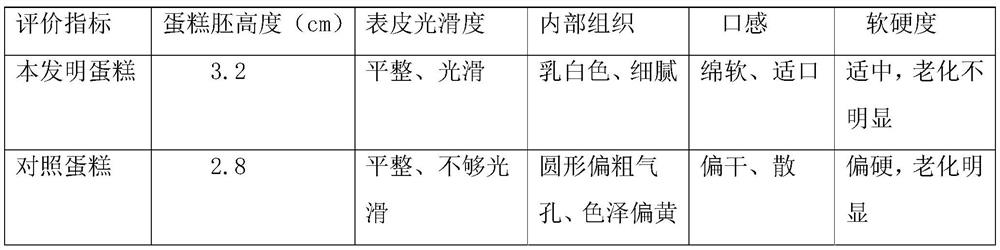

Embodiment 3

[0052] Example 3: The compound emulsion stabilizer is composed of the following raw materials in parts by mass: 4 parts of potassium chloride, 5 parts of gum arabic, 5 parts of propylene glycol alginate, and 40 parts of maltodextrin.

[0053] The preparation method of sponge cake for evaluation of the present invention:

[0054] Raw materials: 600g egg liquid, 300g white sugar, 1g salt, 20g cake oil, 2g citric acid, 30g sorbitol liquid, 300g cake powder, 3g baking powder, 100g salad oil, 40g compound emulsification stabilizer.

[0055] Process:

[0056] (1) Store all materials in a refrigerator at a temperature of 15° C., and use them after the temperature stabilizes.

[0057] (2) Preheat the oven to 180°C and 165°C for later use.

[0058] (3) Beat the eggs into a mixing bucket, add salt, citric acid, white sugar, sorbitol liquid, cake oil, and compound emulsification stabilizer, and beat with a mixer until it turns white and forms a thick foam.

[0059] (4) Sift the cake f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com