Connecting structure for wall bodies at two sides of prefabricated composite wall and method thereof

A technology of connection structure and connection method, which is applied in the direction of underwater structures, basic structure engineering, walls, etc., can solve the problems of deformation and dislocation of walls on both sides, and affect the pre-embedding of water and electricity, etc., so as to avoid deformation and dislocation, uniform force and The effect of stability and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

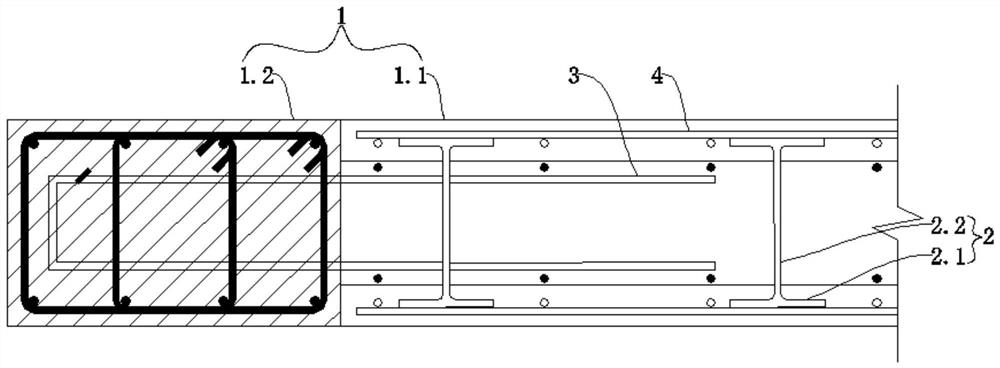

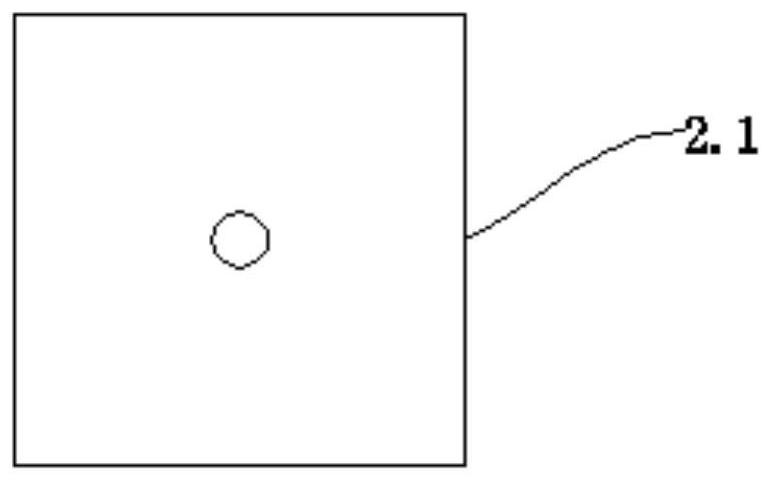

[0034] Such as Figure 1-3 As shown, this embodiment provides a wall connection structure on both sides of a prefabricated laminated wall, including a laminated wall 1 and connectors 2. Several groups of connectors 2 are provided on the front and rear sides of the laminated wall 1, and the connectors 2 are in the form of "I" shape, the height of the connector 2 is 300-400mm, and the distance between adjacent connectors 2 on the same side is 500-600mm.

[0035] In this embodiment, "I"-shaped connectors 2 are used to replace the traditional "V"-shaped truss at the joints of the walls on both sides of the laminated wall 1. Compared with the traditional "V"-shaped truss structure, the "V"-shaped Type trusses are unevenly stressed up and down, and the stress surfaces are mainly concentrated on the left and right sides, and the direction of the force gradually changes. However, the shape of the "I"-shaped connector 2 adopted in the present invention is regular, and the stress surfac...

Embodiment 2

[0043] Such as Figure 1-3 As shown, this embodiment provides a method for connecting the walls on both sides of the prefabricated laminated wall 1, including the following steps:

[0044] S1: Fix and arrange the steel bars on the front and rear sides of the laminated wall 1, and then establish two upper and lower formworks 4 on the front and rear sides of the laminated wall 1, and establish several connecting pieces 2 between the two formworks 4. ", the height of the connector 2 is 300-400mm, and the distance between adjacent connectors 2 on the same side is 500-600mm;

[0045] S2: pouring is performed between the two formworks 4 on the front of the laminated wall 1, and the connector 2 is pre-embedded;

[0046] S3: Turn over the trolley to close the mold;

[0047] S4: pouring is performed on the two formworks 4 on the back side of the laminated wall 1, and the connectors 2 are pre-embedded to obtain a finished product.

[0048]In this embodiment, "I"-shaped connectors 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com