Auxiliary tool for quick installation of cotter pins and method for quick installation of cotter pins

A technology for installing openings and auxiliary tools. It is applied in the direction of manufacturing tools and hand-held tools. It can solve the problems of easy bending and deformation of cotter pins, reduced stress intensity of cotter pins, and poor installation accuracy, so as to preserve stress intensity and avoid Deformation and misalignment, avoiding the effect of repeated adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

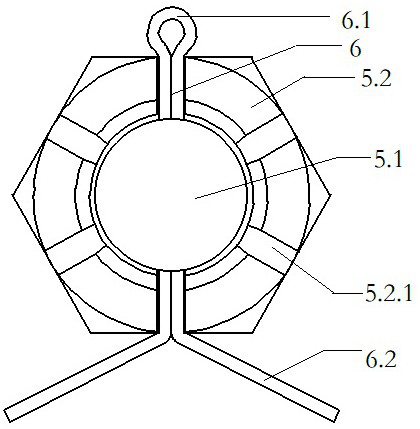

Embodiment 1

[0046] This embodiment discloses an auxiliary tool for quick installation of cotter pins. As a basic embodiment of the present invention, it includes an angle dividing device and a positioning device; the angle dividing device includes a positioning module I1 for placing a nut workpiece 5 and a positioning module for The bending module 2 for bending the cotter pin 6, the sliding body structure I1.1 is arranged on both sides of the positioning module I1, the inner wall I2.2.2 on both sides of the bending module 2 is provided with the chute I2.2.1, the sliding body structure I1 .1 Cooperate with the chute I2.2.1 to make the positioning module I1 and the bending module 2 detachable and slidingly connected; the positioning device includes the positioning module II3 for placing the nut workpiece 5 and the positioning module 4 for rewinding the cotter pin 6 , the two sides of the positioning module Ⅱ 3 are provided with a sliding body structure Ⅱ 3.1, and the inner wall Ⅱ on both sid...

Embodiment 2

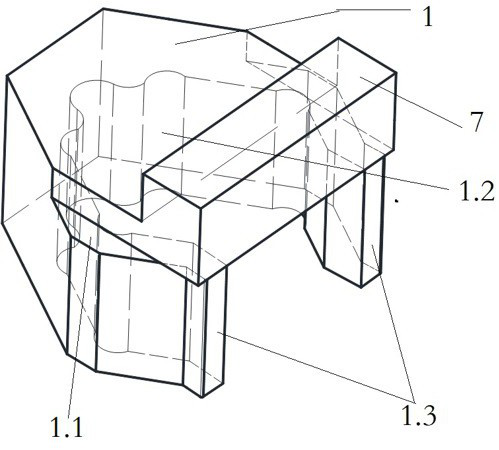

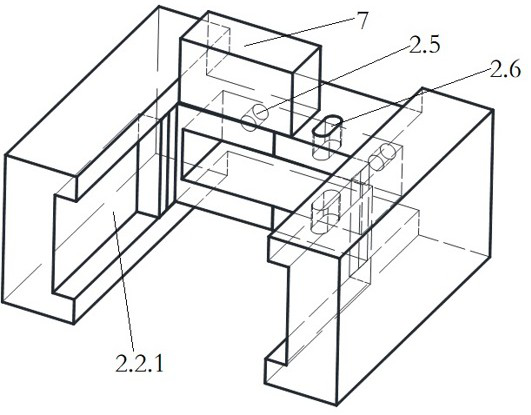

[0049] This embodiment discloses an auxiliary tool for quickly installing cotter pins. As a preferred embodiment of the present invention, that is, in embodiment 1, a workpiece groove 1.2 for placing a nut workpiece 5 is provided in the positioning module I1, and a workpiece groove 1.2 One of the side openings is set, and the two sides of the opening are provided with a pressing piece protrusion 1.3 for supporting the cotter pin 6; the bending module 2 includes a lifting stress table 2.1 for cooperating with the pressing piece protrusion 1.3 to squeeze the cotter pin 6 And the outer frame base 2.2 for installing the lifting stress platform 2.1, the chute I2.2.1 is arranged on the inner wall I2.2.2 of the outer frame base 2.2; the lifting stress platform 2.1 is arranged inside the outer frame base 2.2, and the lifting The bottom of the stress table 2.1 is provided with a spring assembly 2.3, and the lifting stress table 2.1 is movably connected with the outer frame base 2.2 thro...

Embodiment 3

[0052] This embodiment discloses an auxiliary tool for quick installation of cotter pins, as a basic implementation of the present invention, that is, in embodiment 2, a push pin for fixing the lifting stress platform 2.1 is embedded on the outer frame base 2.2 Mechanism 2.4, push latch mechanism 2.4 includes pin 2.4.1, push bouncer 2.4.2 and twist cap 2.4.3, one end of pin 2.4.1 and twist cap 2.4.3 pass through push bouncer 2.4.2 Movably connected, the lifting stress table 2.1 is provided with a pin groove 2.1.1, and the other end of the pin column 2.4.1 cooperates with the pin groove 2.1.1 to prevent the lifting stress table 2.1 from falling; the spring assembly 2.3 includes a positioning column 2.3.1 , the positioning column 2.3.1 is wound with a stress spring 2.3.2; the bottom of the outer frame base 2.2 is provided with a socket 2.5, and one end of the positioning column 2.3.1 is fixedly connected with the bottom of the lifting stress platform 2.1, and the positioning colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com