Construction method of shaft type underground stereo garage

A technology of three-dimensional garages and construction methods, which is applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of waste of structural size, reduction of usable area, waste of land resources, etc., and achieve small environmental impact, fast construction speed, and energy saving The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The present invention will be further described below with reference to the drawings and specific embodiments.

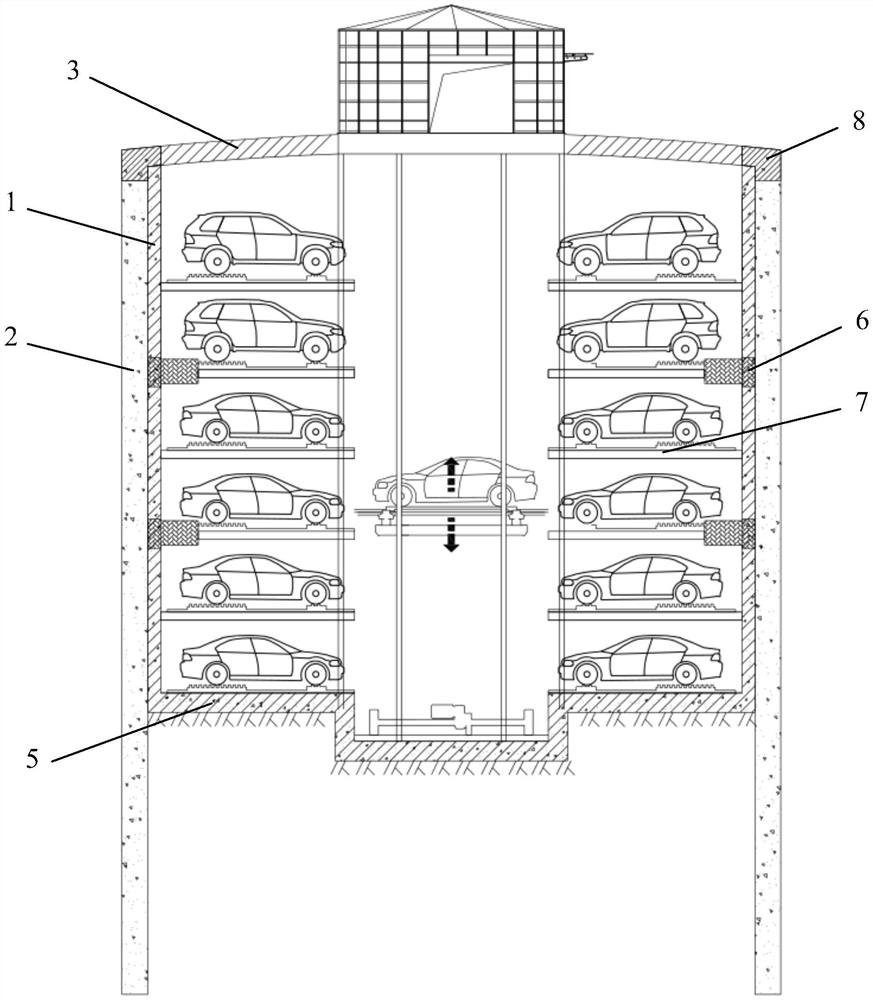

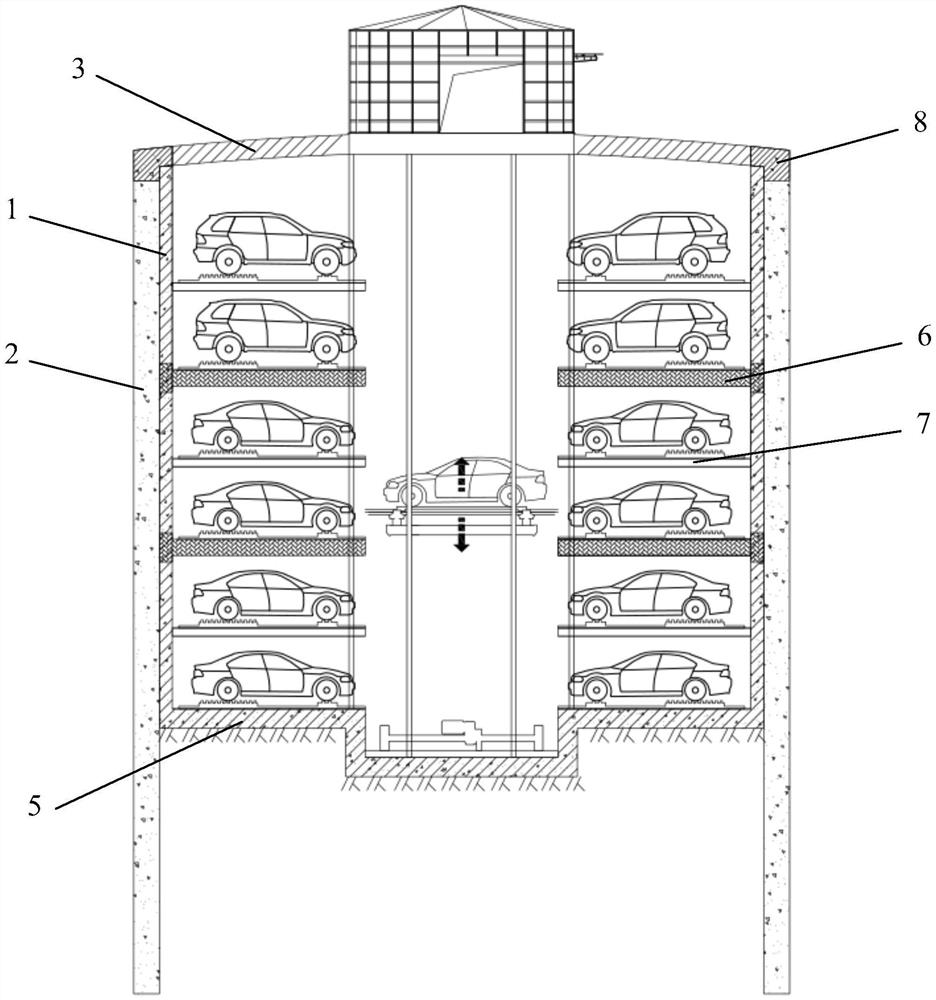

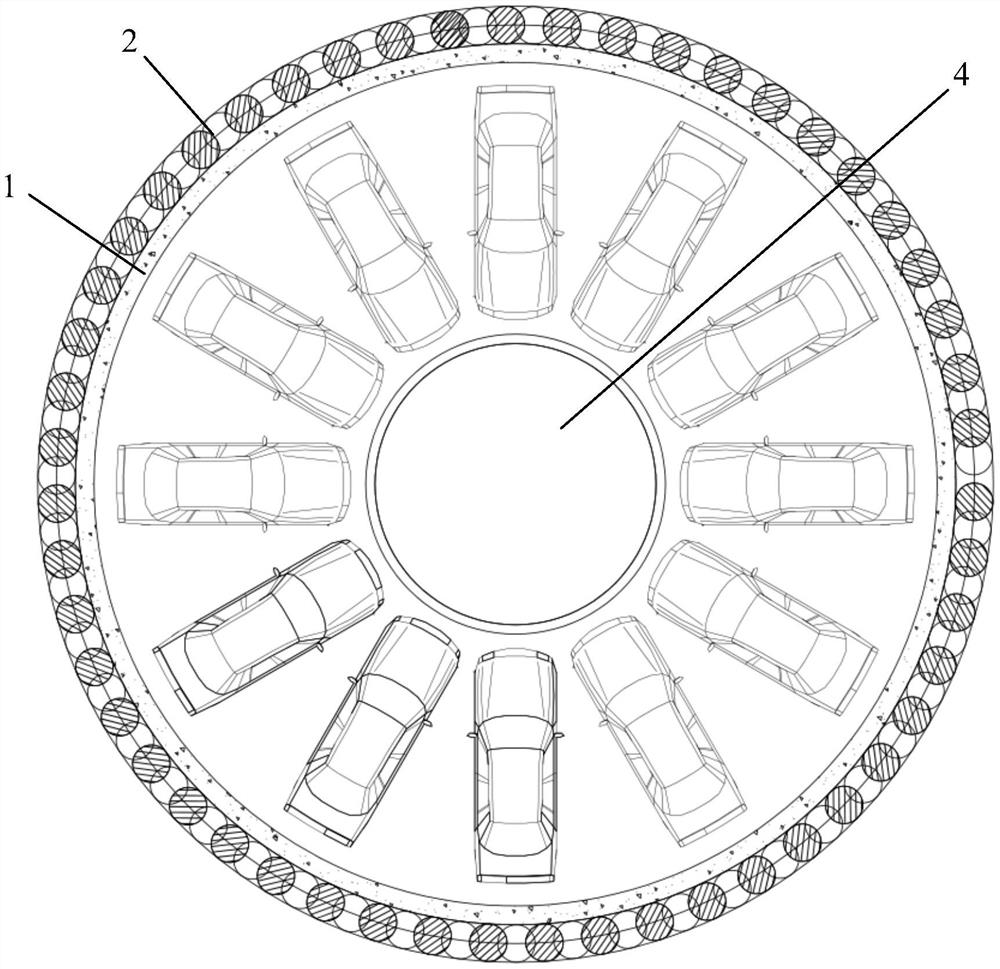

[0043]Such asFigure 1 ~ 4As shown, a construction method of a wellbed underground stereo galar, characterized in that the following steps are included:

[0044]Step 1: Erotive support structure (2) along the outer edge construction of the underground stereo garage (2), and the underlying water level is taken under the water level;

[0045]Step 2: Place the venue surrounded by the vertical support structure (2);

[0046]Step 3: Break the top superfilling part of the vertical support structure (2), leaking the steel bar;

[0047]Step 4: Template in the venue, tie the steel bars, make the roof structure (3); the outer edge of the top plate structure (3) is connected to the vertical support structure (2) top leakage of the vertical support structure, and the whole pouring top plate structure ( 3) Concrete; the top plate structure (3) is left in the middle, and the hole port (4) is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com