Cable-pulled miter dam

A dam and cable technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of limited use conditions, unscientific structural force, and clumsy bottom shaft, etc., to achieve scientific force, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

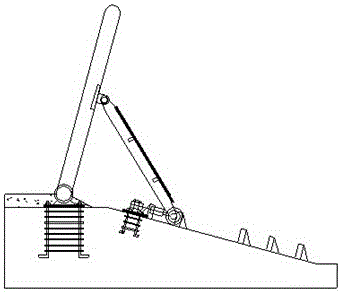

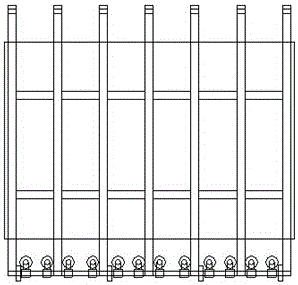

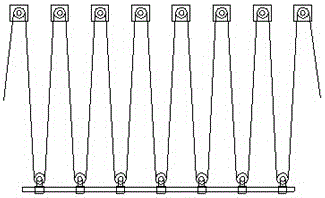

[0032] In order to understand the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0033] see figure 1 — Figure 12 , the water blocking panel 1 is connected to the hinge support 9 through the bottom shaft 8, the hinge support 9 is firmly welded on the steel plate, and the steel plate is firmly welded to the steel cage 10 buried in the dam foundation, thereby fixing the water blocking panel 1 on the dam foundation The back of the water blocking panel 1 is connected with transmission support rods 2, which are arranged in a row at equal distances. The lower end of the transmission support rods 2 is connected to the movable pulley block 5, and the fixed pulley block 4 is installed on the upper end of the dam foundation. forward and reverse to realize dam erection and dam collapse; when the water retaining panel 1 rotates to the predetermined water retaining level, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com