Converter ladder bottom blowing co 2 Method for extracting vanadium

A converter and ladder technology is applied in the field of vanadium metallurgy, which can solve the problems of incomplete melting, fast rhythm, and quenching phenomenon in the molten pool, and achieve the effect of inhibiting the heating of the molten pool and reducing the residual vanadium content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

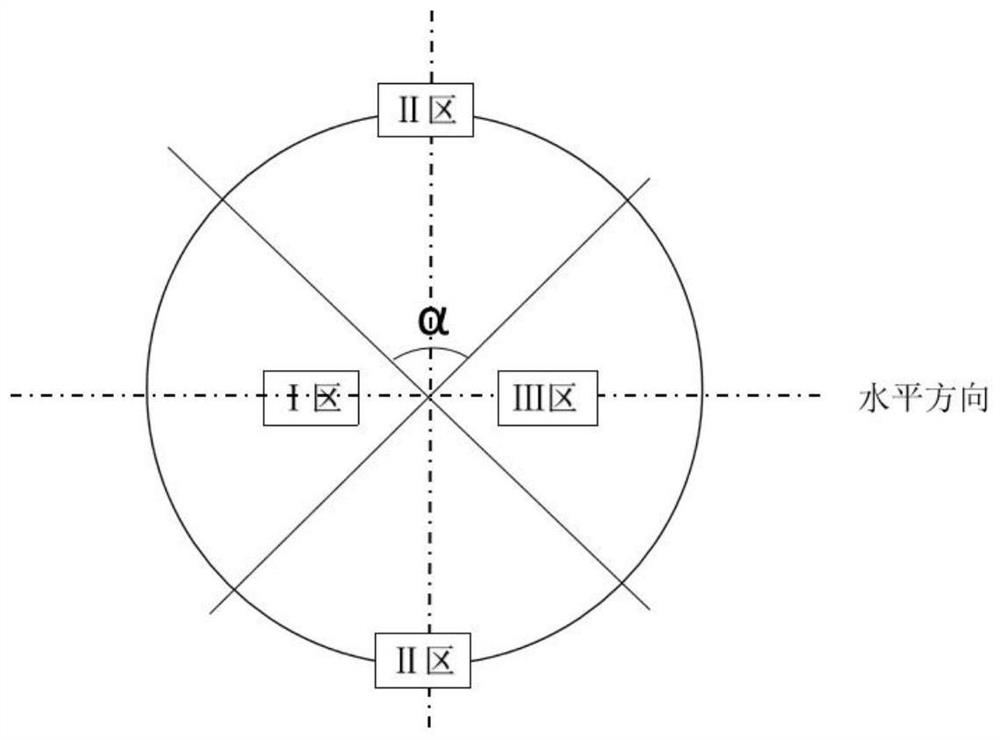

[0024] The molten iron with a V content of 0.28-0.34% is mixed into the converter, and the temperature of the molten iron is controlled to be 1260-1320 ° C. The air-permeable bricks are distributed in the bottom zone I, II and III of the converter. The number of permeable bricks matches the furnace capacity, of which zone I The ventilation bricks in zone III are symmetrically distributed, the ventilation bricks in zone II are symmetrically distributed, and the included angle α in zone II is 80°. Blow CO at the bottom of the converter after shaking the furnace 2 , among which, CO is blown from the bottom of a single breathable brick in Zone I 2 Flow is 100Nm 3 / min, CO is blown from the bottom of a single breathable brick in the Ⅱ zone 2 Flow is 140Nm 3 / min, CO is blown from the bottom of a single breathable brick in zone III 2 Flow is 180Nm 3 / min, at the same time, the top of the oxygen lance is used to blow O 2 , the oxygen supply intensity of the oxygen lance is 1.5~...

Embodiment 2

[0026] The molten iron with a V content of 0.28-0.34% is mixed into the converter, and the temperature of the molten iron is controlled to be 1260-1320 ° C. The air-permeable bricks are distributed in the bottom zone I, II and III of the converter. The number of permeable bricks matches the furnace capacity, of which zone I The ventilation bricks in zone III are symmetrically distributed, the ventilation bricks in zone II are symmetrically distributed, and the included angle α of zone II is 90°. Blow CO at the bottom of the converter after shaking the furnace 2 , among which, CO is blown from the bottom of a single breathable brick in Zone I 2 Flow is 120Nm 3 / min, CO is blown from the bottom of a single breathable brick in the Ⅱ zone 2 Flow is 160Nm 3 / min, CO is blown from the bottom of a single breathable brick in zone III 2 Flow is 200Nm 3 / min, at the same time, the top of the oxygen lance is used to blow O 2 , the oxygen supply intensity of the oxygen lance is 1.5~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com