A kind of extinction ultra-low temperature curing powder coating composition and coating thereof

A powder coating, ultra-low temperature technology, used in powder coatings, coatings, polyester coatings, etc., can solve the application occasions that are difficult to meet the matte or low-gloss coating effect, and the cured coating is difficult to achieve matte or low-gloss effect. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of extinction ultra-low temperature curing powder coating composition, adopt the raw material shown in following table 1:

[0031] The formula of matting ultra-low temperature curing powder coating composition in the embodiment 1 of table 1

[0032] Raw material type parts by weight Specific raw material model High Acid Value Polyester Resin 725 Using TG0003 from Guangzhou Qingtian GMA acrylic resin 250 Using GMA1618 from Ningbo Nanhai Chemical Defoamer 10 Using POWDERMATE 542DG from Troy Degasser 5 With OXYMELT A4 from Estron leveling agent 10 Using BYK 3900P Total 1000 /

Embodiment 2

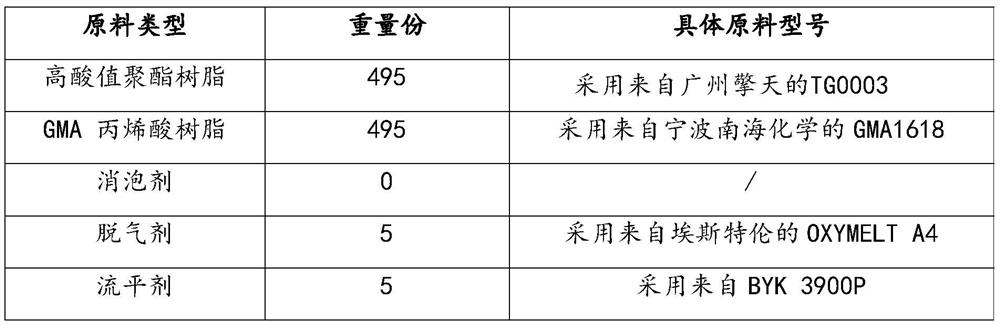

[0033] Embodiment 2: A kind of extinction ultra-low temperature curing powder coating composition, adopt the raw material shown in following table 2:

[0034] The formula of matting ultra-low temperature curing powder coating composition in the embodiment 2 of table 2

[0035]

Embodiment 3

[0036] Embodiment 3: A kind of extinction ultra-low temperature curing powder coating composition, adopt the raw material shown in following table 3:

[0037] The formula of matting ultra-low temperature curing powder coating composition in the embodiment 3 of table 3

[0038] Raw material type parts by weight Specific raw material model High Acid Value Polyester Resin 600 Using TG0003 from Guangzhou Qingtian GMA acrylic resin 400 Using GMA1618 from Ningbo Nanhai Chemical Defoamer 0 / Degasser 0 / leveling agent 0 / Total 1000 /

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com