Method for detecting cracking of weld seam of withdrawal and straightening machine

A technology of tension leveling machine and detector, which is applied in the direction of length measuring device, roll safety equipment, optical device exploration, etc., and can solve problems affecting production operation rate, long processing time, and steel strip loss of tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

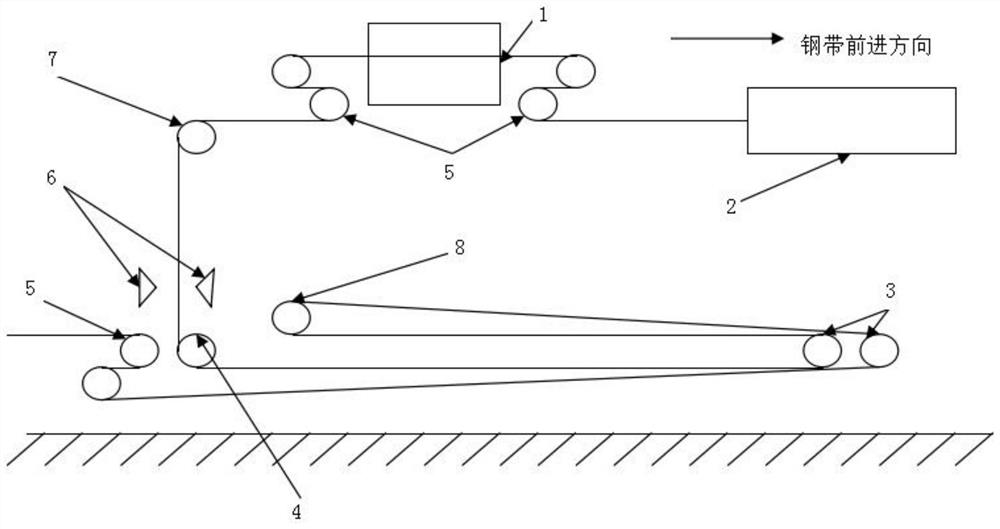

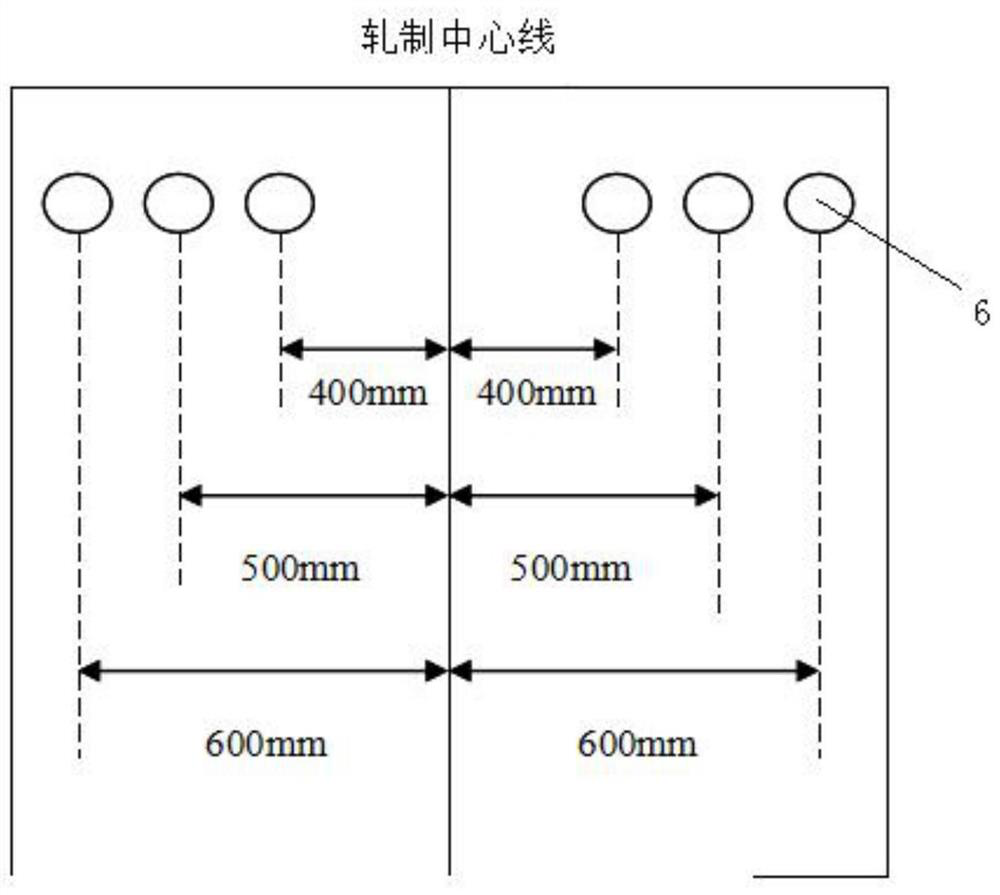

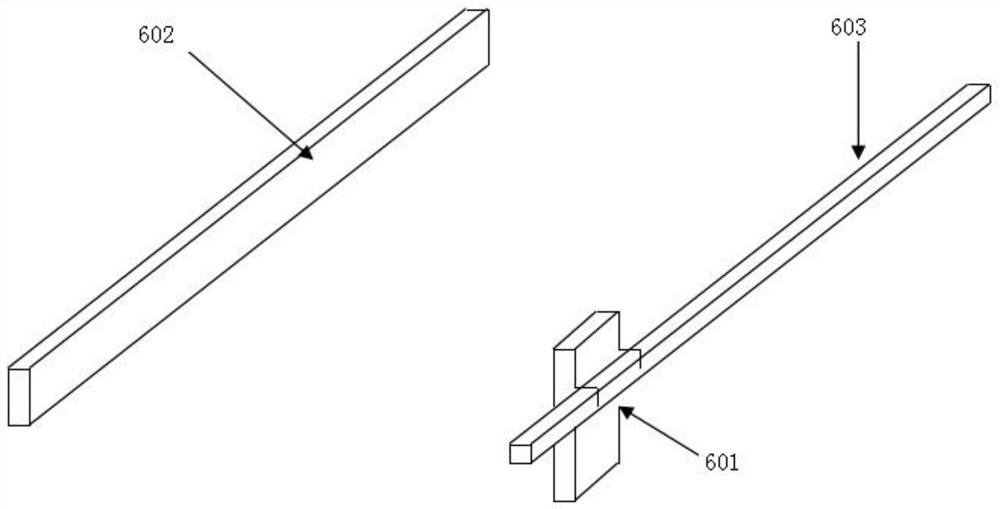

[0020] A method for detecting the open welding of tension-leveler weld seams, in which a grating detector 6 is installed at the rear of No. 3 deviation-correcting roll 4 of the acid-rolling combined unit (i.e. behind the last deviation-correcting roll before the tension-leveler) to detect the steel strip, See the specific configuration location figure 1 , the emitter 601 of the grating emits the light source signal, and the receiver 602 of the grating receives the light source signal. Under normal production conditions, due to the barrier of the steel plate, the grating cannot sense the signal. Once the signal is sensed by the grating, it means that the weld seam of the steel plate is open. The grating detector 6 sends an emergency stop signal to the production line, and the operator checks and confirms the weld seam .

[0021] The raw material of the acid-rolling combined unit suitable for the present invention comes from the CSP production line or the production line whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com