An integral adjustment bar coating die head

An adjustment bar and integral technology, which is applied in the direction of surface coating liquid devices, coatings, climate sustainability, etc., can solve the problems of slurry pollution, lithium battery safety hazards, etc., and achieve the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

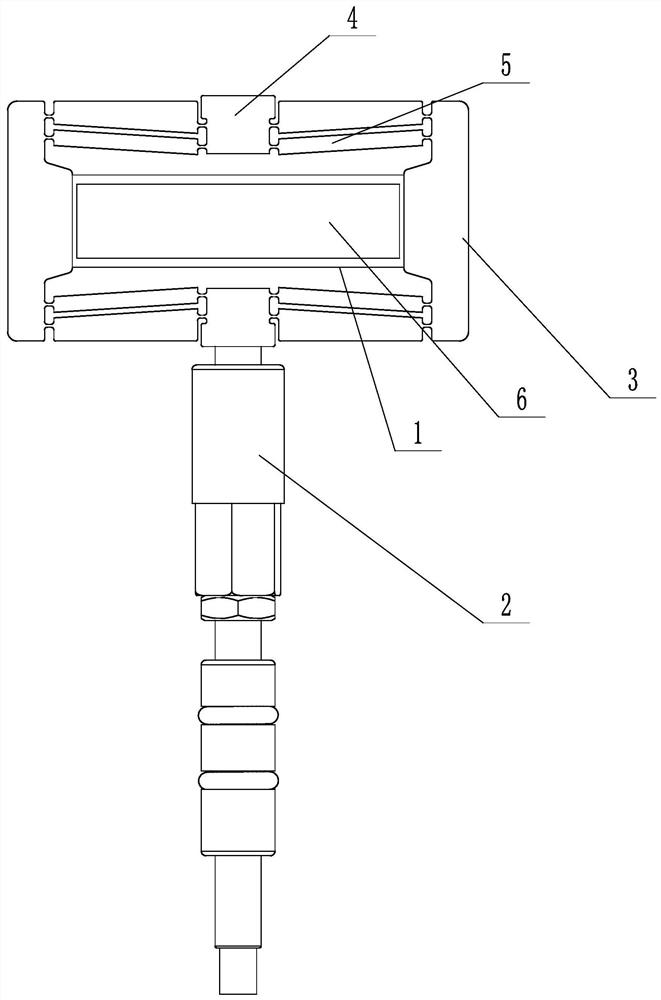

[0023] see Figure 1 to Figure 4 , an integral adjustment bar coating die head, comprising a lower mold 8, an upper mold 9, an adjusting gasket 10 between the lower mold 8 and the upper mold 9, a liquid storage tank 11 located on the upper side of the lower mold 8, a The squeeze block 12 in the liquid storage tank 11, the chute 13 located on the lower side of the upper mold 9, the adjustment bar 14 slidingly connected in the chute 13, and the adjustment device for lifting the adjustment bar 14;

[0024] The liquid squeezing block 12 is fixedly connected to the lower side of the adjusting gasket 10, and the adjusting gasket 10 separates the upper die 9 and the lower die 8 to form a slurry outlet channel 15. The liquid storage tank 11 and the liquid squeezing block 12 forms a squeeze channel 16 with a U-shaped cross-section, one end of the squeeze channel 16 is blocked by an adjusting gasket 10, the other end of the squeeze channel 16 communicates with the slurry outlet channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com