Preparation method of sewage treatment catalyst and application of sewage treatment catalyst in sewage treatment

A sewage treatment and catalyst technology, applied in the direction of adsorption water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unfavorable catalytic degradation efficiency, weak adsorption of pollutants, and difficult separation. Achieve the effect of simple preparation process, low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

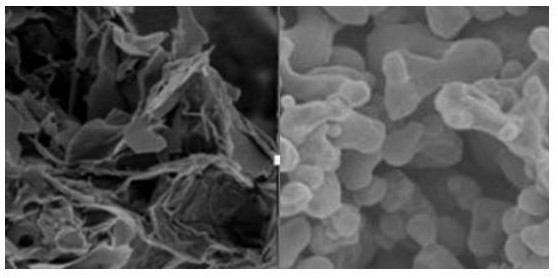

[0035] (1) Mn 3 o 4 Synthesis of @GA airgel: Weigh 2 mg of graphene oxide and dissolve it in 50 mL of deionized water, and perform ultrasonic treatment to obtain a uniform suspension, which is marked as dispersion 1. Subsequently, 20 g of ethanol solution (18 g of ethanol, 2 g of water) was added to the above dispersion 1 and continued stirring to obtain dispersion 2. Weigh 30 mg of Mn(Ac) 2 4H 2 0 and 10 mg of L-lysine were added to the dispersion 2, and the stirring was continued to obtain a suspension 3, and then the suspension 3 was transferred to an autoclave lined with polytetrafluoroethylene, and transferred to an oven 120 ºC for 6 h. After the reaction, the obtained black product was washed several times to remove excess unreacted components and impurities. The product was freeze-dried at -30 ºC for 36 h. The collected samples are labeled as Mn 3 o 4 @GA-1.

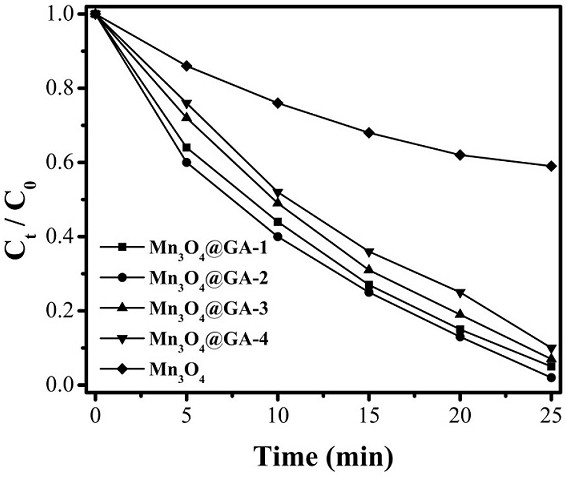

[0036] (2) Mn 3 o 4 @GA airgel catalytic oxidation of phenol solution: select 200 mL of phenol with ...

Embodiment 2

[0038] (1) Mn 3 o 4 Synthesis of @GA airgel: 4 mg of graphene oxide was weighed and dissolved in 50 mL of deionized water, and subjected to ultrasonic treatment to obtain a uniform suspension, marked as dispersion 1. Subsequently, 20 g of ethanol solution (16 g of ethanol, 4 g of water) was added to the above dispersion 1 and continued stirring to obtain dispersion 2. Weigh 40 mg of Mn(Ac) 2 4H 20 and 20 mg of L-lysine were added to the dispersion 2, and the stirring was continued to obtain a suspension 3, and then the suspension 3 was transferred to an autoclave lined with polytetrafluoroethylene, and transferred to an oven 120 ºC for 10 h. After the reaction, the obtained black product was washed several times to remove excess unreacted components and impurities. The product was freeze-dried at -40 ºC for 36 h. The collected samples are labeled as Mn 3 o 4 @GA-2.

[0039] (2) Mn 3 o 4 @GA Airgel Catalyzed Oxidation of Phenol Solution: Follow the degradation condit...

Embodiment 3

[0041] (1) Mn 3 o 4 Synthesis of @GA airgel: Weigh 5 mg of graphene oxide and dissolve it in 50 mL of deionized water, and perform ultrasonic treatment to obtain a uniform suspension, which is marked as dispersion 1. Subsequently, 20 g of ethanol solution (10 g of ethanol, 10 g of water) was added into the above dispersion 1 and continued stirring to obtain dispersion 2. Weigh 50 mg of Mn(Ac) 2 4H 2 0 and 20 mg of L-lysine were added to the dispersion 2, and the stirring was continued to obtain a suspension 3, and then the suspension 3 was transferred to an autoclave lined with polytetrafluoroethylene, and transferred to an oven 140 ºC for 12 h. After the reaction, the obtained black product was washed several times to remove excess unreacted components and impurities. The product was freeze-dried at -30 ºC for 48 h. The collected samples are labeled as Mn 3 o 4 @GA-3.

[0042] (2) Mn 3 o 4 @GA Airgel Catalyzed Oxidation of Phenol Solution: Follow the degradation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com