Inert gas protection method during combustion of explosion-proof lithium battery power supply

A technology of inert gas and lithium batteries, which is applied in the direction of electrical components, battery pack parts, battery and its environment isolation, etc., can solve safety accidents, cannot meet the special requirements of mine explosion-proof equipment, and the explosion intensity of battery packs is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

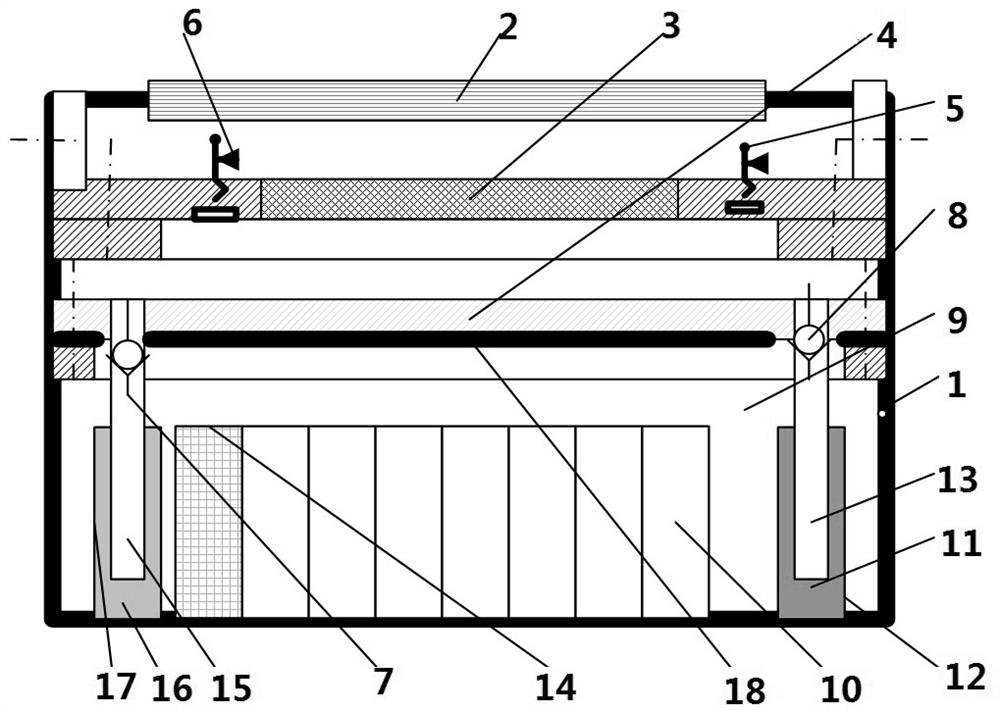

[0030] Embodiment one, with reference to the attached figure 2 , the flame arrester 3 is a corrugated flame arrester, which is composed of a flame arrester frame 3-1 and a multilayer flame arrester net 3-2, and the multilayer flame arrester net 3-2 is arranged in the flame arrester frame 1 3-1, and the flame arrester frame A 3-1 is fixed on the side wall of the battery case 1.

Embodiment 2

[0031] Embodiment two, referring to the attached image 3 , the flame arrester 3 is an explosion-proof flat flame arrester, composed of a flame arrester frame 2 3-3 and a plurality of flame arrester sheets 3-4, and a plurality of flame arrester sheets 3-4 are arranged in the flame arrester frame 2 3-3, and the flame arrester Firearm frame two 3-3 is fixed on the side wall of battery casing 1.

[0032] The battery case 1 is made of metal steel plate or plastic with a certain strength. Since the interior of the battery case 1 is not under pressure or slight pressure, the shell is light in weight and the energy-to-weight ratio of the battery pack is increased.

[0033] The battery pack 10 of the present invention is installed in a closed space filled with inert gas, and the effect of the inert gas 9 is: when the battery pack 10 causes combustion and explosion due to external factors such as overcharging and over-discharging, the battery pack 10 is in a state of isolating oxygen, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com