Horizontal reaction kettle and shaft sealing device for horizontal reaction kettle

A horizontal reaction kettle and shaft sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as affecting normal production, weakening sealing effect, shaft sealing wear, etc., achieving remarkable sealing effect, convenient loading and unloading, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

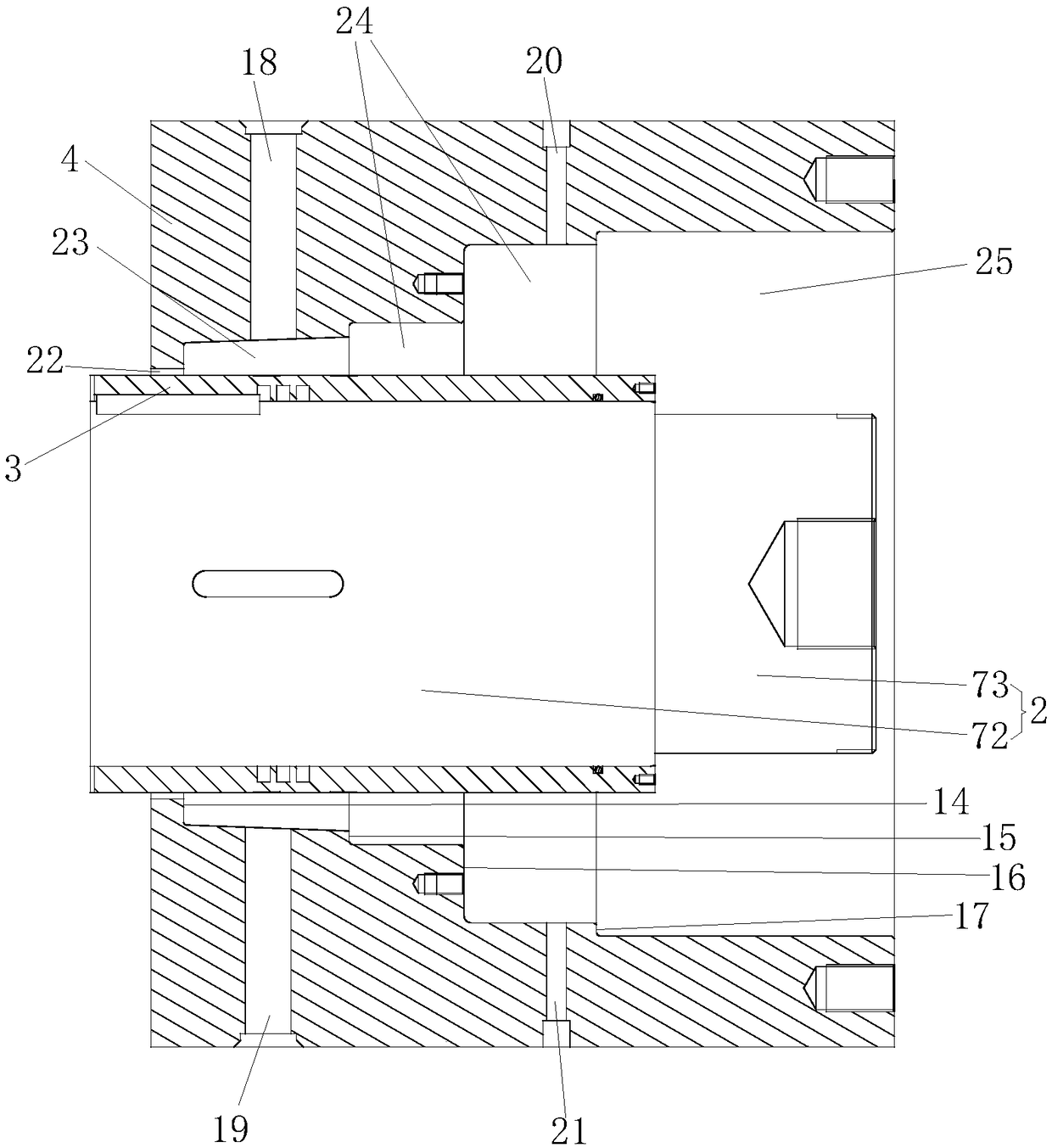

[0050] Depend on figure 1 As shown, the present invention provides a shaft sealing device for a horizontal reaction kettle, which is provided with a shaft head 2, and a shaft sleeve 3 is fixedly sleeved on the shaft head 2, and a support seat 4 is provided outside the shaft sleeve 3, and the support seat 4 It may be a cylindrical structure, and a sealing structure assembly is provided between the outer peripheral surface of the shaft sleeve 3 and the inner peripheral surface of the support seat 4 . A bearing assembly is provided at the end of the shaft head 2. The bearing assembly is provided with a bearing 5, a bearing chamber 6 and a bearing gland 7. The bearing 5 is fixedly sleeved at the end of the shaft head 2, and the bearing 5 is arranged between the bearing chamber 6 and the bearing gland 7. In the enclosed space 53 surrounded by the bearing gland 7 . The bearing chamber 6 is fixedly connected with the support seat 4, the first shaft oil seal 8 is connected between th...

Embodiment 2

[0067] Depend on Figure 31 As shown, the present invention provides a shaft sealing device for a horizontal reactor. On the basis of Embodiment 1, the end of the shaft head 2 is passed through the bearing gland 7 and protruded out. The shaft head 2 and the bearing gland 7 By using the second shaft oil seal 101 for sealing connection, the second shaft oil seal 101 can be a special-shaped oil seal, and the second shaft oil seal 101 is connected with the shaft head 2 in a circumferential sliding manner; the structure, connection relationship, main principle of sealing of other parts of the present invention and The installation method of the shaft sealing device is the same as that of Embodiment 1, and will not be described again, as the shaft sealing device at the other end of the stirring shaft 1 in the horizontal reactor. The end of the shaft head 2 that passes through the bearing gland 7 and protrudes is connected to the power output shaft of the external power drive device....

Embodiment 3

[0069] The horizontal reaction kettle is usually mainly composed of four parts: the kettle body, the stirring shaft with stirring blades, the power drive device and the shaft sealing device. The shaft sealing device is installed on the left and right ends of the kettle body, and the top of the kettle body is opened , The bottom of the kettle body is provided with a discharge port. The shaft sealing device described in Embodiment 1 is installed on the left end face of the still body of this embodiment, and the shaft sealing device described in Embodiment 2 is installed on the right end face of the kettle body; between the shaft sealing devices described in Embodiment 1 and Embodiment 2 The synergistic effect, its structure is simple, easy to disassemble and assemble, can effectively solve the shortcomings of poor sealing effect caused by the infiltration of reaction materials, high-heat gas infiltration and high-temperature heat conduction to the sealing structural components of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com