Chicken manure organic fertilizer processing stirring equipment with cleaning function

A mixing equipment and organic fertilizer technology, which is applied in the direction of mixer accessories, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problems of reducing the practicability of the device, single mixing, and affecting the quality of chicken manure organic fertilizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

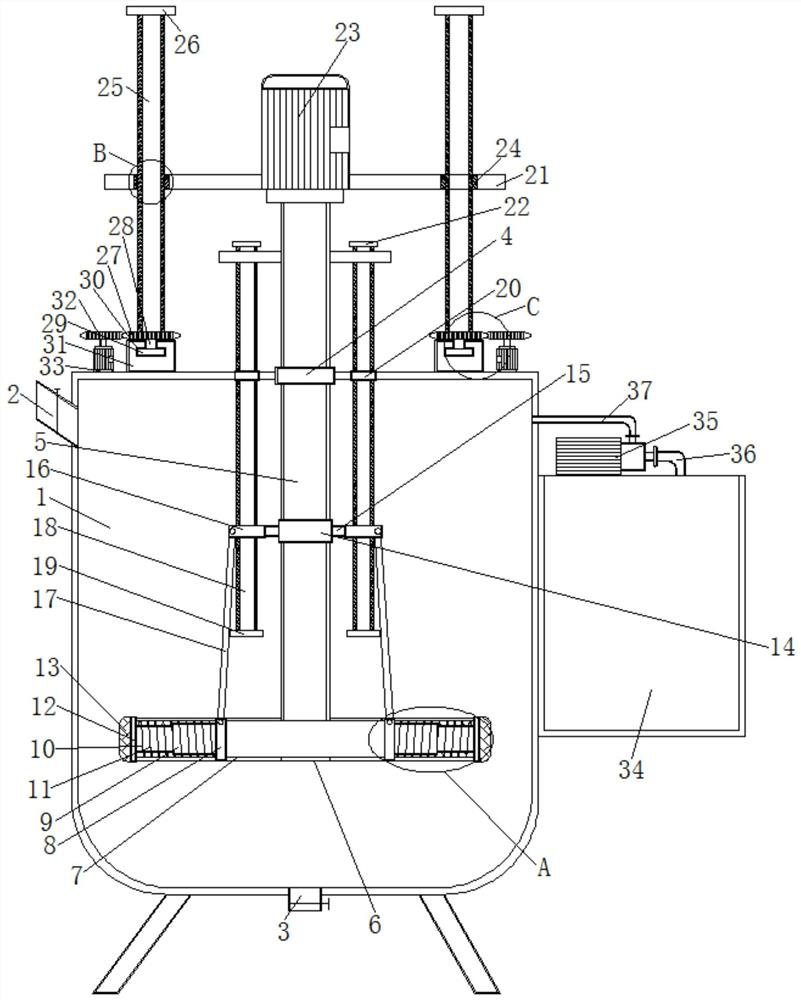

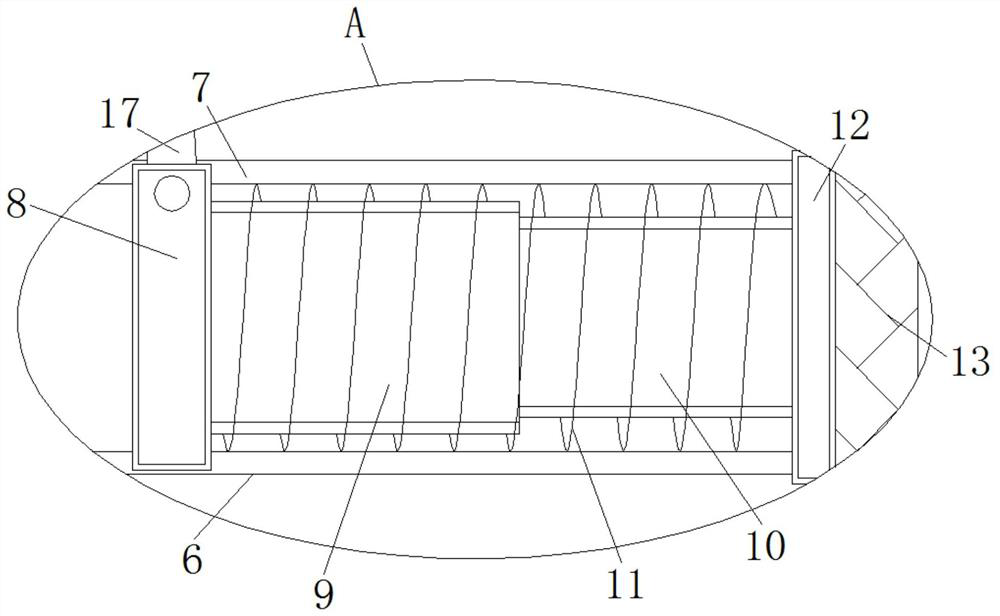

[0027] Such as Figure 1-4As shown, according to the processing of chicken manure organic fertilizer according to the embodiment of the present invention, the stirring equipment with cleaning function includes a stirring tank 1, a feed port 2 and a discharge port 3, and an inlet is provided on the left side of the top of the stirring tank 1. A feed port 2, a discharge port 3 is opened in the middle of the bottom of the stirring tank 1, a cleaning device is arranged inside the stirring tank 1, a connection port 4 is fixedly connected in the middle of the top of the stirring tank 1, and the connection port 4 runs through the middle A round rod 5 is inserted, the bottom end of the round rod 5 is fixedly connected with a stirring rod 6, the left and right sides of the top and bottom of the stirring rod 6 are provided with chutes 7, and the four groups of the chute 7 are embedded with Embedded rods 8, the opposite sides of the two groups of embedded rods 8 are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com