Stirring device and stirring system

A stirring device and stirring component technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve problems such as difficult removal of the tank, difficult maintenance, explosion, etc., to improve the stirring effect and improve the stirring efficiency. Efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

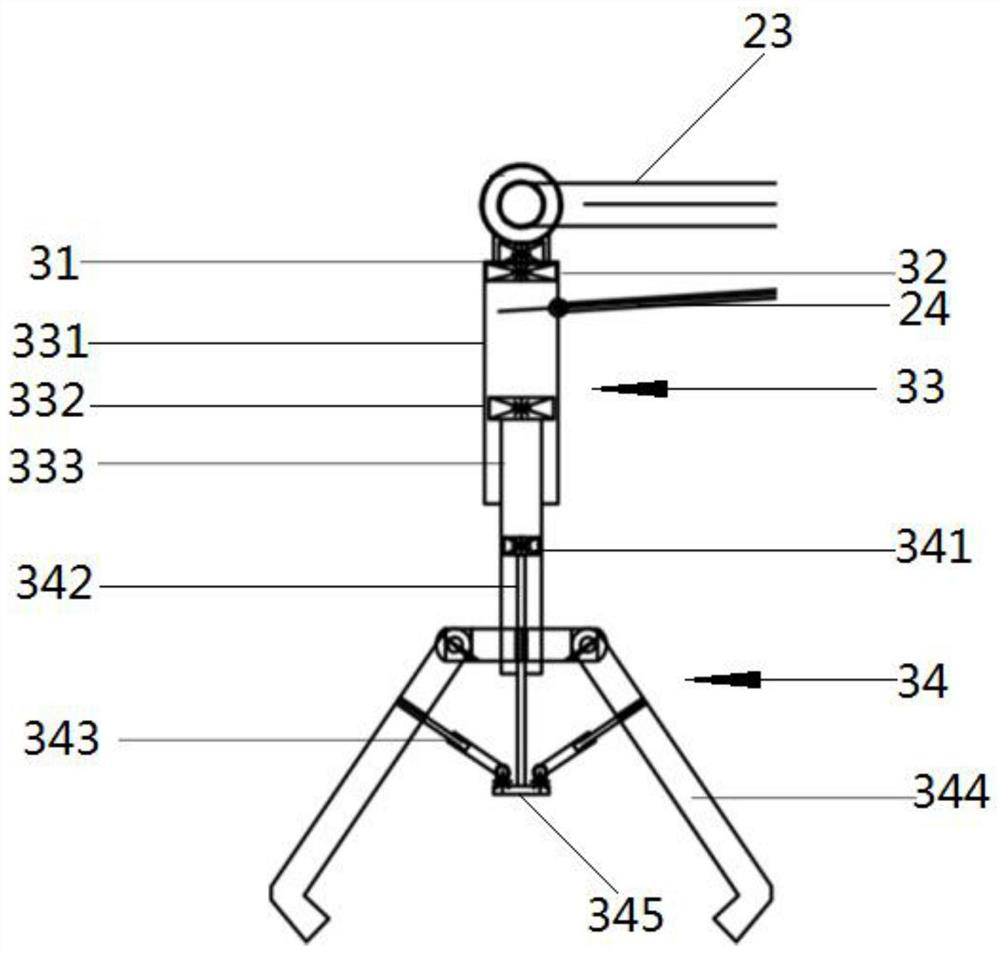

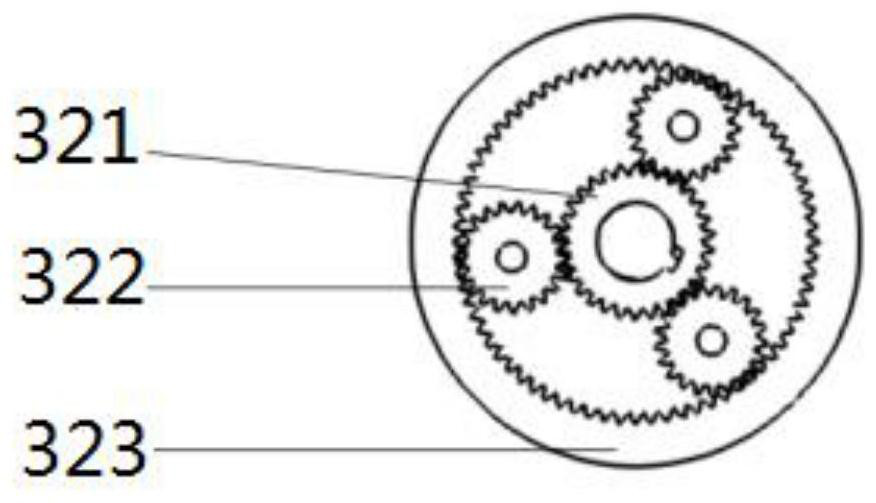

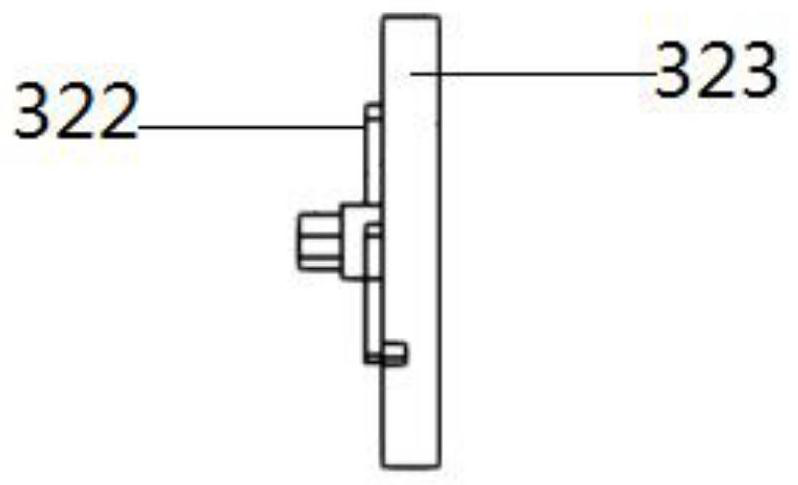

[0029] Such as Figure 1-Figure 4 As shown, this embodiment provides a stirring device, which is mainly used for biogas engineering stirring, including a control element 1, a traction assembly 2 and a stirring assembly 3, the traction assembly 2 is electrically connected to the control element 1, and the stirring assembly 3 is installed on the traction assembly 2 above, and the control element 1 can control the traction assembly 2 to drive the agitation assembly 3 to extend into or out of the biogas engineering tank 4, so as to ensure that when agitation is required, the agitation assembly 3 is controlled to agitate the tank body 4, and when the agitation assembly 3 appears When there is a breakdown or maintenance is required, the stirring assembly 3 is removed for external inspection, which is convenient for maintenance, so as to ensure the smooth progress of the subsequent stirring work, and the stirring assembly 3 can be used at different positions of the same level in the t...

Embodiment 2

[0040] Such as Figure 4 As shown, this embodiment provides a stirring system, including a tank body 4 and the stirring device described in any one of the first embodiment, the tank body 4 is used to place materials, and the side wall of the tank body 4 is provided with a maintenance and the inspection port is opened close to the upper end of the tank body 4 to prevent materials from being discharged through the inspection port. The inspection port is placed, and the traction device can drive the stirring device to extend into or out of the tank body 4 through the inspection port, which is convenient for the inspection of the stirring device, and there is no need to disassemble the tank body 4, so the maintenance is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com