Paint dispersing device

A technology of dispersing device and coating, applied in mixers with rotary stirring device, transportation and packaging, dissolving, etc., can solve the problems of easy formation of lumps of materials, affecting the normal production of the company, and small contact surfaces, so as to ensure normal production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

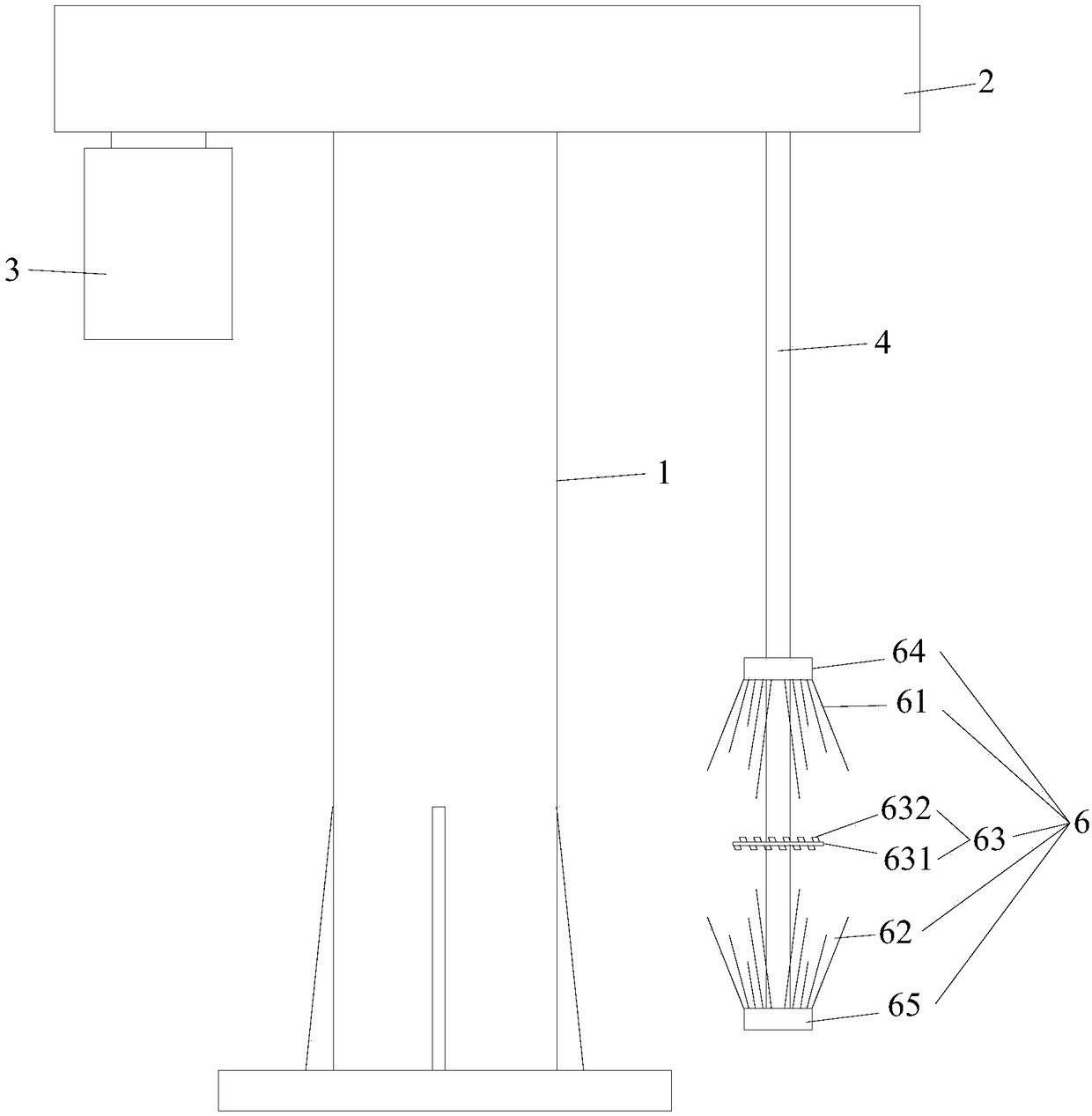

[0018] Please refer to figure 1 , the paint dispersing device includes a column 1, a cross arm 2 installed on the upper end of the column 1, a driving device 3 is installed on one end of the cross arm 2, a rotating shaft 4 is installed on the other end of the cross arm 2, and the driving device 3 passes through the transmission device Linked with the rotating shaft 4, the lower end of the rotating shaft 4 is equipped with a dispersion structure 6.

[0019] There are ribs 11 distributed at equal intervals on the outside of the lower part of the column 1 . The cross arm 2 is hollow inside, and the transmission device is located inside the cross arm 2 . The driving device 3 is a motor, and the output shaft of the motor and the upper end of the rotating shaft 4 all extend into the cross arm 2 inside. The transmission devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com