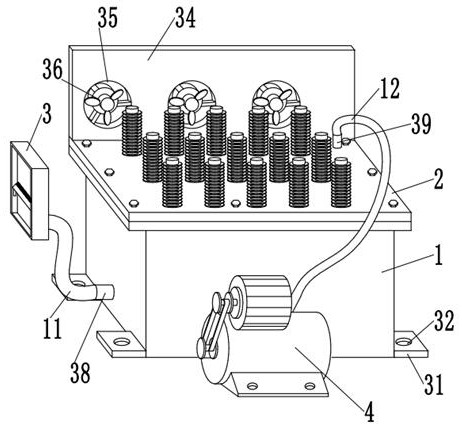

Heat dissipation mechanism for new energy battery management

A technology for battery management and heat dissipation mechanism, which is applied to secondary batteries, battery pack components, and isolation of batteries from their environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

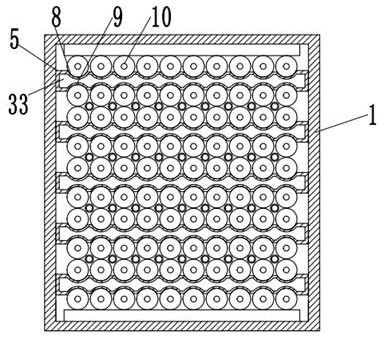

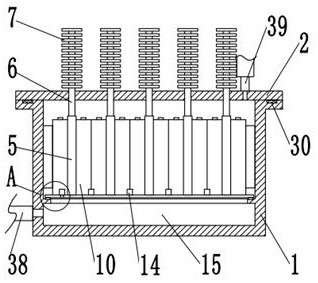

Embodiment 1

[0044] A dust removal device for a heat dissipation mechanism for new energy battery management, comprising a box body 1, the inside of the box body 1 is provided with uniformly distributed heat dissipation plates 5, the interior of the heat dissipation plate 5 is provided with a vacuum chamber 33, and the interior of the vacuum chamber 33 is in a vacuum state. With pure water, pure water is used as the refrigerant, and the battery body 10 is evenly distributed between two adjacent cooling plates 5, and the outer wall of one side of the cooling plate 5 is provided with evenly distributed left-shaped grooves 8, and the battery body 10 Compatible with the left-shaped groove 8, the outer wall of one side of the cooling plate 5 is provided with evenly distributed right-shaped grooves 9, and the battery body 10 is adapted to the right-shaped groove 9, and the top outer wall of the cooling plate 5 is welded with equidistant distribution. radiating pipe 6, the top of the radiating pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com