Method for measuring mass of free electrolyte in lithium ion battery

A technology of lithium ion battery and measurement method, applied in the field of lithium ion battery manufacturing, can solve problems such as increase of electrolyte solution and hidden danger of battery safety, and achieve the effects of reducing waste, saving manufacturing cost and accurate measurement result.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for measuring the quality of free electrolyte in a lithium ion battery, comprising the following steps:

[0028] 1), weigh the total mass M of the lithium-ion battery 总 ;

[0029] 2) Disassemble the lithium-ion battery, wipe off the electrolyte on the outer surface of the battery cell and the inner and outer surfaces of the packaging case, and weigh the total mass M of the dried battery cell and the packaging case. 干 ;

[0030] 3), calculate the mass m of the free state electrolyte in the lithium-ion battery, m=M 总 -M 干 .

[0031] Preferably, the lithium-ion battery is a soft-packed lithium-ion battery, an aluminum shell battery or a steel shell battery with the air bag removed. The packaging shell is aluminum plastic film, aluminum shell or steel shell.

[0032] Preferably, an electronic balance is used for weighing, and the electronic balance is first balanced and zeroed before use.

[0033] Preferably, the weighing accuracy of the electronic balance i...

Embodiment 2

[0035] A method for measuring the quality of free electrolyte in a lithium ion battery, comprising the following steps:

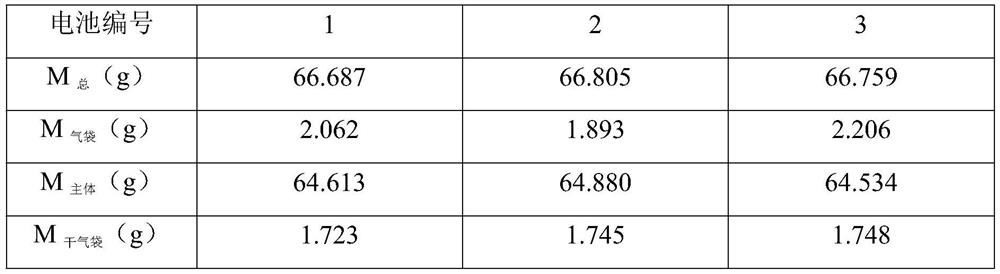

[0036] 1), weigh the total mass M of the lithium-ion battery 总 ;

[0037] 2), cut off the air bag along the two edges of the lithium-ion battery, and weigh the quality M of the air bag respectively 气袋 and the mass of the battery body M 主体 ;

[0038] 3) Wipe off the residual electrolyte inside and outside the air bag, and weigh the mass M of the air bag after drying. 干气袋 ;

[0039] 4) Disassemble the main body of the battery, wipe off the electrolyte on the outer surface of the battery cell and the inner and outer surfaces of the packaging case, and weigh the total mass M of the dried battery cell and the packaging case 干主体 ;

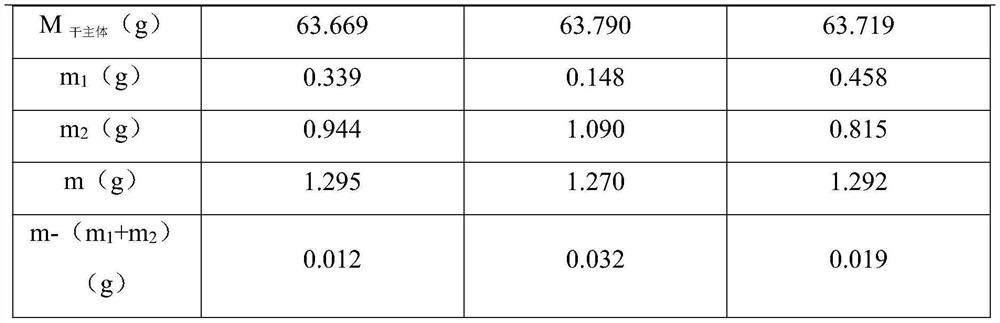

[0040] 5), respectively calculate the mass m of the free electrolyte in the air bag 1 , the mass of free electrolyte in the battery body m 2 and the total mass m of the free electrolyte in the lithium-ion battery, where m 1 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com