Corn stalk cotton processing system based on intelligent control

A processing system and corn stalk technology, applied in the field of corn stalk processing, can solve the problems of low degree of automation, low digestibility, inaccurate detection, etc., and achieve the effect of efficient and accurate operation and efficient crushing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

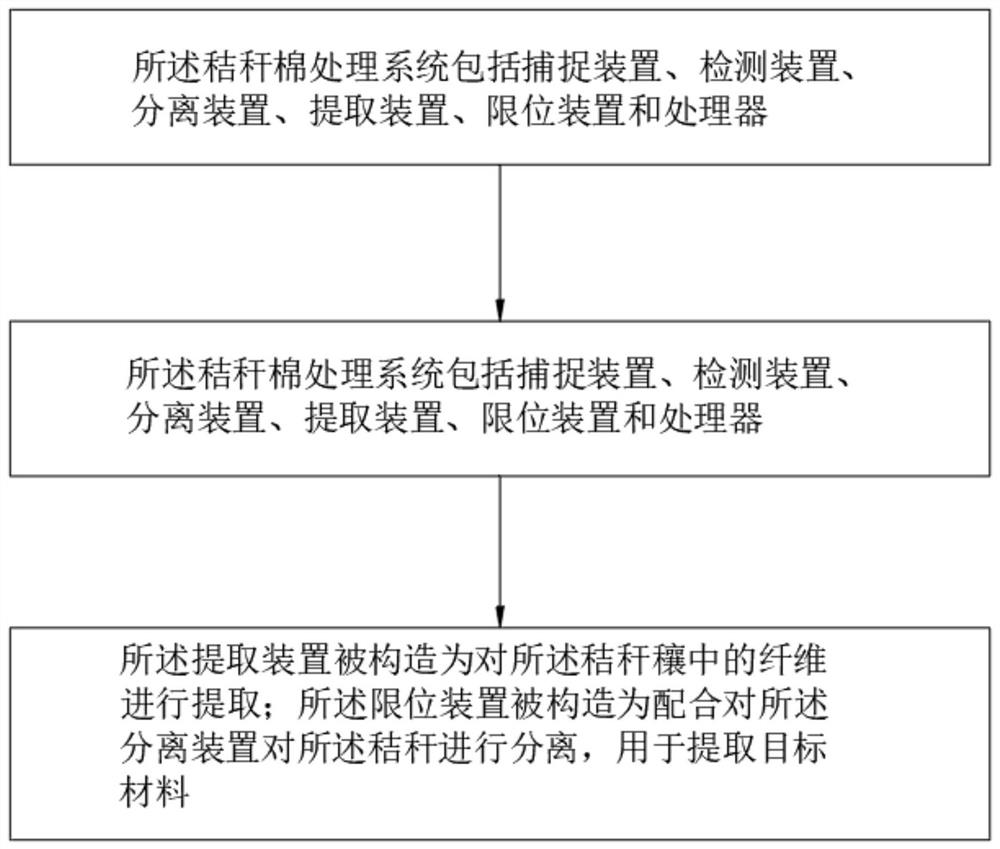

[0032] Embodiment 1: A corn stalk cotton processing system based on intelligent control, the straw cotton processing system includes a capture device, a detection device, a separation device, an extraction device, a limit device and a processor, and the capture device is configured to The straw is recycled; the detection device is configured to detect the position of the straw; the separation device is configured to separate the straw to obtain the straw; the extraction device is configured to detect the straw Extracting the fibers in the straw; the limiting device is configured to cooperate with the separating device to separate the straw for extracting the target material;

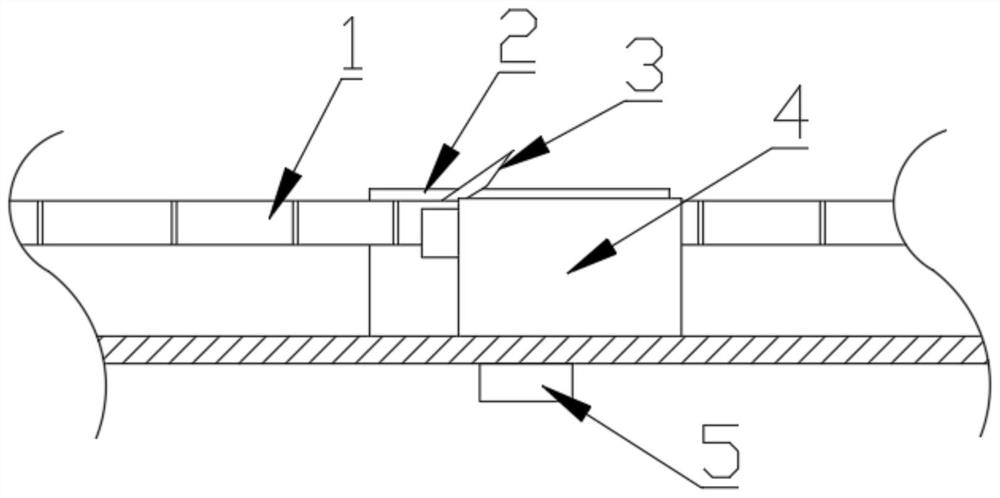

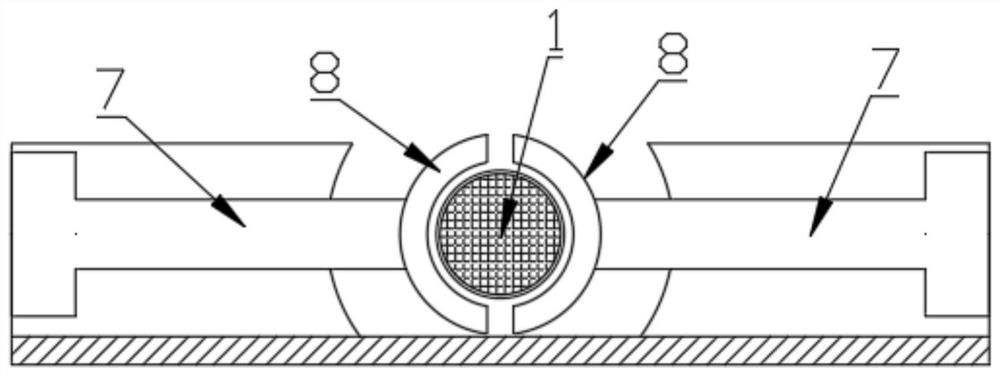

[0033]Optionally, the catching device includes a storage cavity, a catching mechanism and an adjusting mechanism, both the catching mechanism and the adjusting mechanism are set in the storage cavity, and the catching mechanism is configured to be set on the adjusting mechanism, And realize the conversio...

Embodiment 2

[0038] Embodiment 2: At present, straw husks are used as fiber raw materials in the paper industry, especially the invention of the corn stalk husk separator, which plays a key role in the large-scale corn stalk pulping industry; For grazing or returning to the field, the high lignin and free gossypol contained in cotton straw are the main factors affecting the use of cotton straw as feed; because of the high lignin content of cotton straw, it is directly fed to cattle and sheep, which has poor palatability and low digestibility. However, the free gossypol in cotton stalks will lead to unfavorable factors such as slow growth of livestock, weight loss, abortion and stillbirth of pregnant dams due to exceeding the safety limit; Problems such as high cost and inaccurate detection;

[0039] A corn stalk cotton processing system based on intelligent control is provided, the straw cotton processing system includes a capture device, a detection device, a separation device, an extract...

Embodiment 3

[0046] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvement on the basis thereof; provide a corn stalk cotton processing system based on intelligent control, the straw cotton processing system It includes a capture device, a detection device, a separation device, an extraction device, a limit device and a processor, the capture device is configured to recycle the straw; the detection device is configured to detect the position of the straw; The separation device is configured to separate the straw to obtain the straw; the extraction device is configured to extract the fibers in the straw; the limit device is configured to cooperate with the separation The device separates the straw to extract the target material; the processing device is respectively connected with the capture device, the detection device, the separation device, the extraction device, and the limit device, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com