Automatic sample crusher

An automatic sample preparation and pulverizer technology, applied in the preparation of test samples, grain processing, etc., can solve the problems of high labor intensity in feeding operations, unfavorable disassembly and cleaning, and no design of sealing structure, etc., to achieve coal dust collection efficiency High, optimize the crushing operation, reduce the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

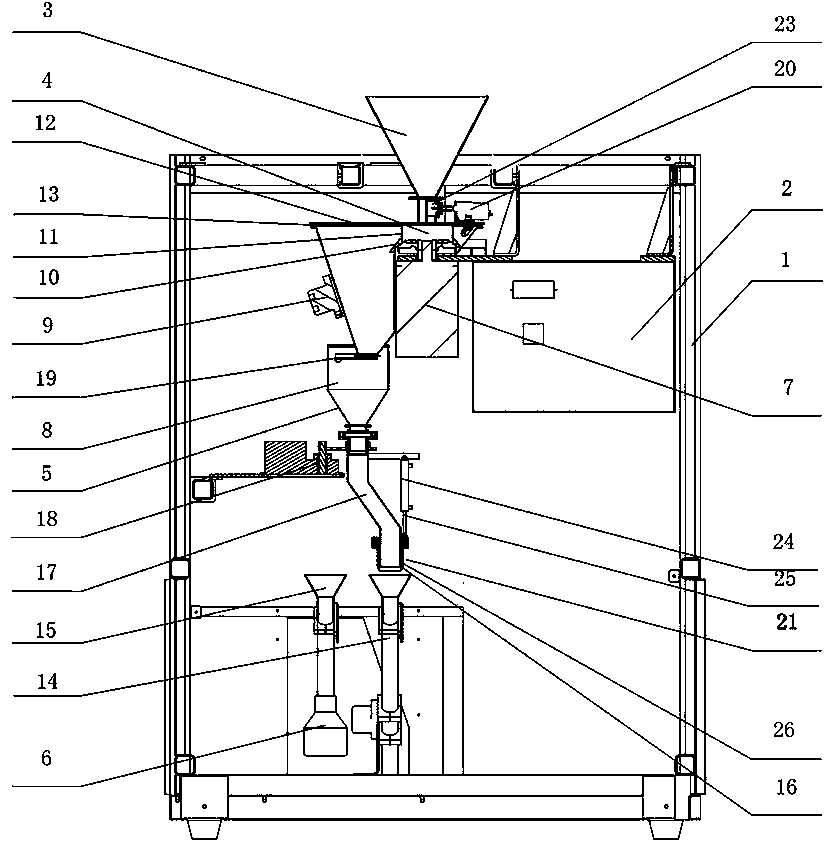

[0030] Such as Figure 1 ~ Figure 4 As shown, the automatic sample preparation pulverizer of the present invention includes a frame 1, a control assembly 2, a pulverizing assembly, a hopper 3, a collection channel 5, a sample discarding channel 14 and a sample retention channel 15, and the hopper 3 is located in the pulverizing assembly The feeding end of the collection channel 5 communicates with the discharge end of the pulverizing assembly, and the sample disposal channel 14 and the sample retention channel 15 are located at the discharge end of the collection channel 5 . The present invention is provided with a discharge pipe 17 at the discharge end of the collection channel 5, and the discharge pipe 17 is arranged on a sample channel switching mechanism 18, and is driven by the sample channel switching mechanism 18 to rotate to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com