Semiconductor wafer epitaxial growth device and working method thereof

An epitaxial growth and semiconductor technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of limiting the detection system's recognition accuracy of defect types, affecting the uniformity of the temperature field on the wafer surface, and limiting the recognition accuracy of the detection system, etc. problem, to achieve the effect of ingenious device structure design, good working stability, and uniformity of temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

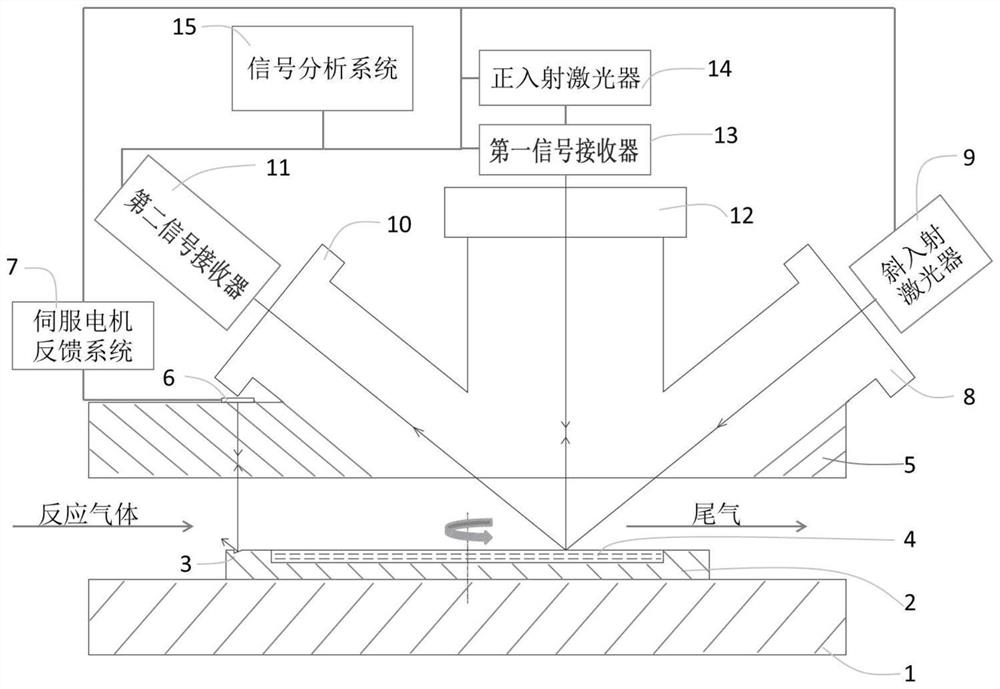

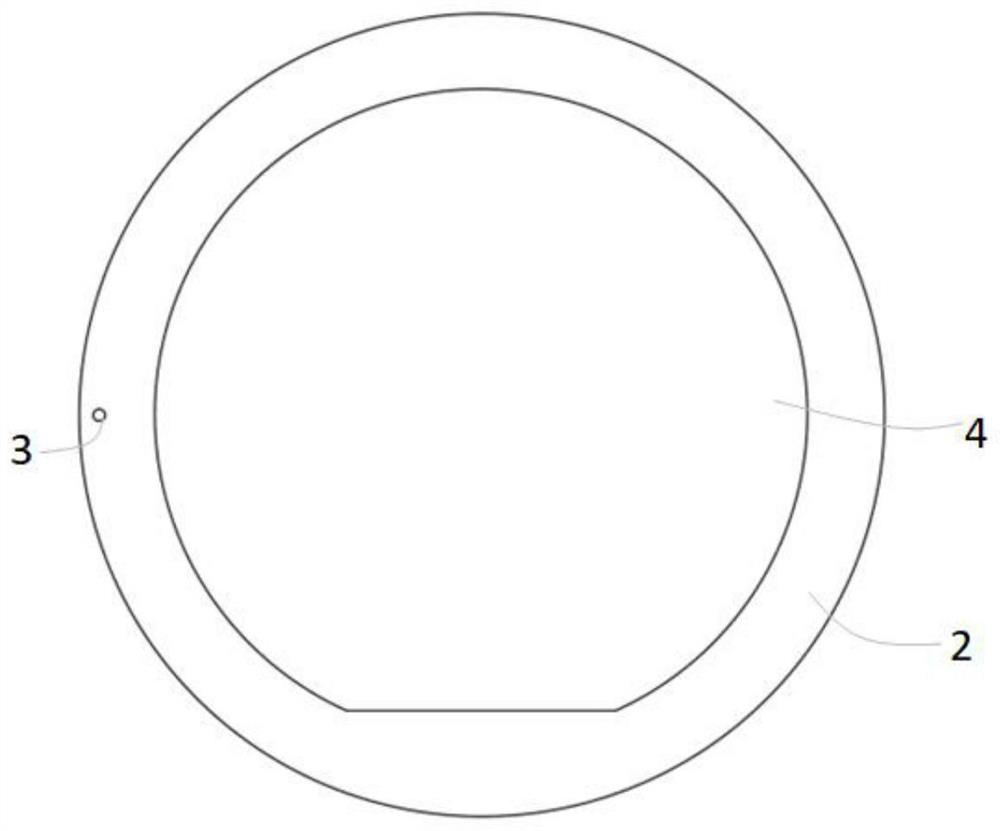

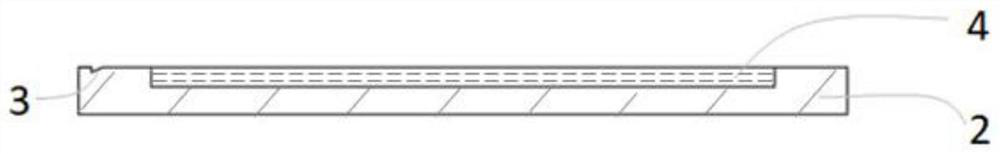

[0028] Embodiment 1: A semiconductor wafer epitaxial growth device and its working method provided in this embodiment, see figure 1 , figure 2 and image 3 , the semiconductor wafer epitaxial growth device includes an epitaxial growth system and an optical surface analysis system, wherein the epitaxial growth system includes a growth chamber and a graphite base 2, and the optical surface analysis system includes a graphite disk speed detector 6, a motor feedback system 7. Signal analysis system 15 , first signal receiver 11 , second signal receiver 13 , oblique incidence laser 9 and normal incidence laser 14 .

[0029] The graphite base 2 is arranged on the bottom 1 of the growth chamber, and the top 2 of the growth chamber is provided with a normal incidence window 12 facing the graphite base 2 and an oblique incidence window 8 obliquely facing the graphite base 2 and signal receiving window. The normal incidence window 12, the oblique incidence window 8 and the signal re...

Embodiment 2

[0042] Embodiment 2: This embodiment provides a semiconductor wafer epitaxial growth device and its working method, which are basically similar to Embodiment 1, except that a tantalum carbide coating is provided on the surface of the graphite base 2 .

[0043] When working, take the wafer substrate as an 8-inch Si wafer substrate as an example:

[0044] (1) Putting the wafer substrate into the graphite base 2 positioned in the growth chamber for in-situ etching of hydrogen and hydrogen chloride;

[0045] (2) Normal incidence laser 14 emits a laser beam perpendicular to the surface of the wafer substrate with a wavelength of 635nm to irradiate the wafer substrate. degree, but not perpendicular to the surface of the wafer substrate, a laser with a wavelength of 635nm is irradiated on the wafer substrate;

[0046] (3) The graphite base 2 drives the wafer substrate to rotate, and combines the normal incidence laser 14 and the oblique incidence laser 9 to perform translational mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com