High-barrier antibacterial composite film based on nano cellulose/MXene immobilized nano silver as well as preparation method and application thereof

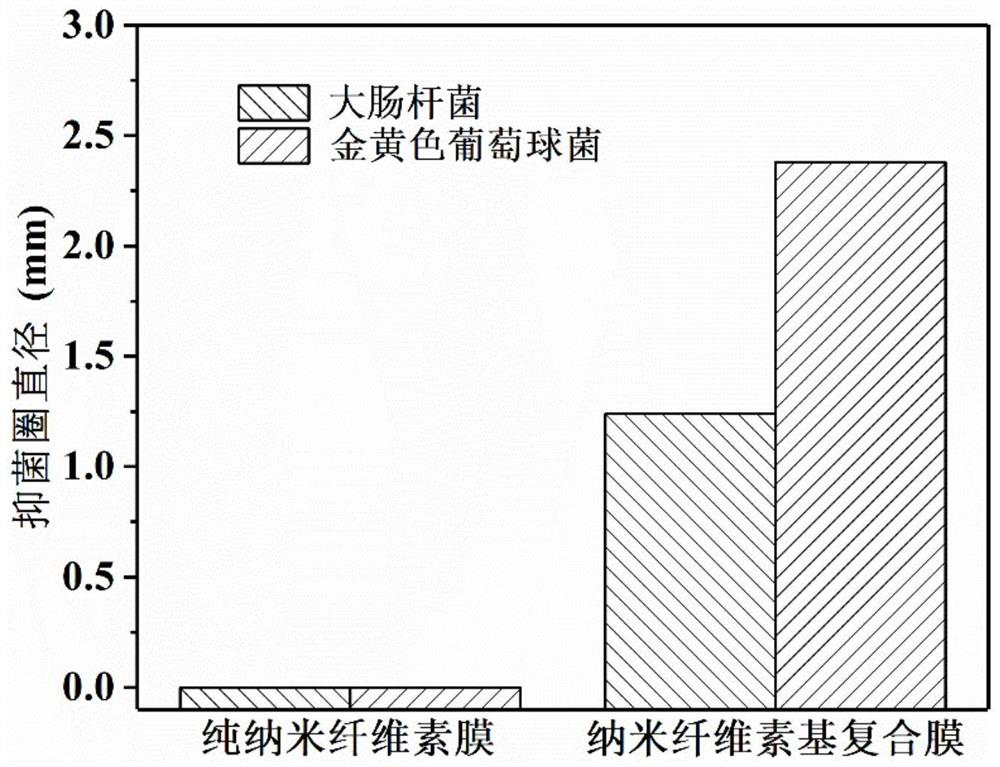

A technology of nano-cellulose and nano-silver, which is applied in the field of food packaging materials, can solve the problems of cumulative toxicity and achieve good antibacterial effect, stable performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of nano-cellulose / MXene immobilized nano-silver high-barrier antibacterial composite film, the specific steps are as follows:

[0036] (1) Using the MXene solution obtained by HCL / LiF stripping, add 1 mL of silver ammonia solution with a concentration of 0.05 mol / L to 50 mL of 0.1 g / L MXene solution under stirring, and mix well to obtain a mixed solution;

[0037](2) Under room temperature conditions, in the mixed solution that step (1) obtains, add the tea polyphenol solution that concentration is 1g / L, obtain reaction solution, tea polyphenol solution is 5% with respect to the total fraction of reaction solution , continue to react for 5 minutes, dialyze the obtained MXene-immobilized nano-silver complex to no silver ion, and obtain MXene-immobilized nano-silver composite antibacterial agent;

[0038] (3) preparation mass fraction is 0.1% nano-cellulose solution (the diameter of nano-cellulose < 15nm), adds glycerol (plasticizer) wherein under stirring...

Embodiment 2

[0045] The preparation of nano-cellulose / MXene immobilized nano-silver high-barrier antibacterial composite film, the specific steps are as follows:

[0046] (1) Using the MXene solution obtained by HCL / LiF stripping, add 7.5 mL of silver ammonia solution with a concentration of 0.4 mol / L to 50 mL of MXene solution with a concentration of 0.9 g / L under stirring, and mix well to obtain a mixed solution;

[0047] (2) Under room temperature conditions, in the mixed solution that step (1) obtains, add the tea polyphenol solution that concentration is 10g / L, obtain reaction solution, the tea polyphenol solution is 7.5% with respect to the total fraction of reaction solution , continue to react for 30 minutes, dialyze the obtained MXene-immobilized nano-silver complex until no silver ions are detected, and obtain nano-cellulose-immobilized nano-silver composite antibacterial agent;

[0048] (3) preparation mass fraction is 2% nano-cellulose solution (the diameter of nano-cellulose <...

Embodiment 3

[0055] The preparation of nano-cellulose / MXene immobilized nano-silver high-barrier antibacterial composite film, the specific steps are as follows:

[0056] (1) Use the MXene solution obtained by HCL / LiF stripping, add 30 mL of silver ammonia solution with a concentration of 2.5 mol / L to 50 mL of 2 g / L MXene solution under stirring, and mix well to obtain a mixed solution;

[0057] (2) Under room temperature conditions, in the mixed solution that step (1) obtains, add the tea polyphenol solution that concentration is 30g / L, obtain reaction solution, tea polyphenol solution is 12% with respect to the total fraction of reaction solution , continue to react for 45 minutes, dialyze the obtained MXene-immobilized nano-silver complex until no silver ions are detected, and obtain the MXene-immobilized nano-silver composite antibacterial agent;

[0058] (3) preparation mass fraction is 4% nano-cellulose solution (the diameter of nano-cellulose < 15nm), adds glycerin (plasticizer) whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com