Material overturning and conveying device of short material sawing and drilling all-in-one machine

A technology of conveying device and integrated machine, which is applied in the direction of conveyor objects, transportation and packaging, metal processing, etc., and can solve the problems of inapplicability and inability to adapt to bars of different diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples.

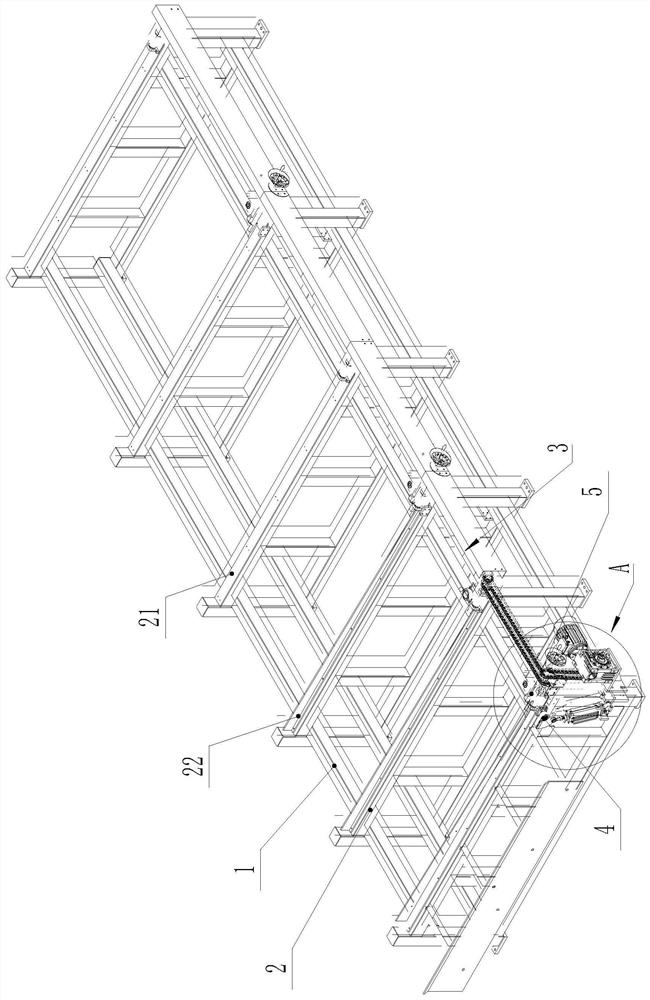

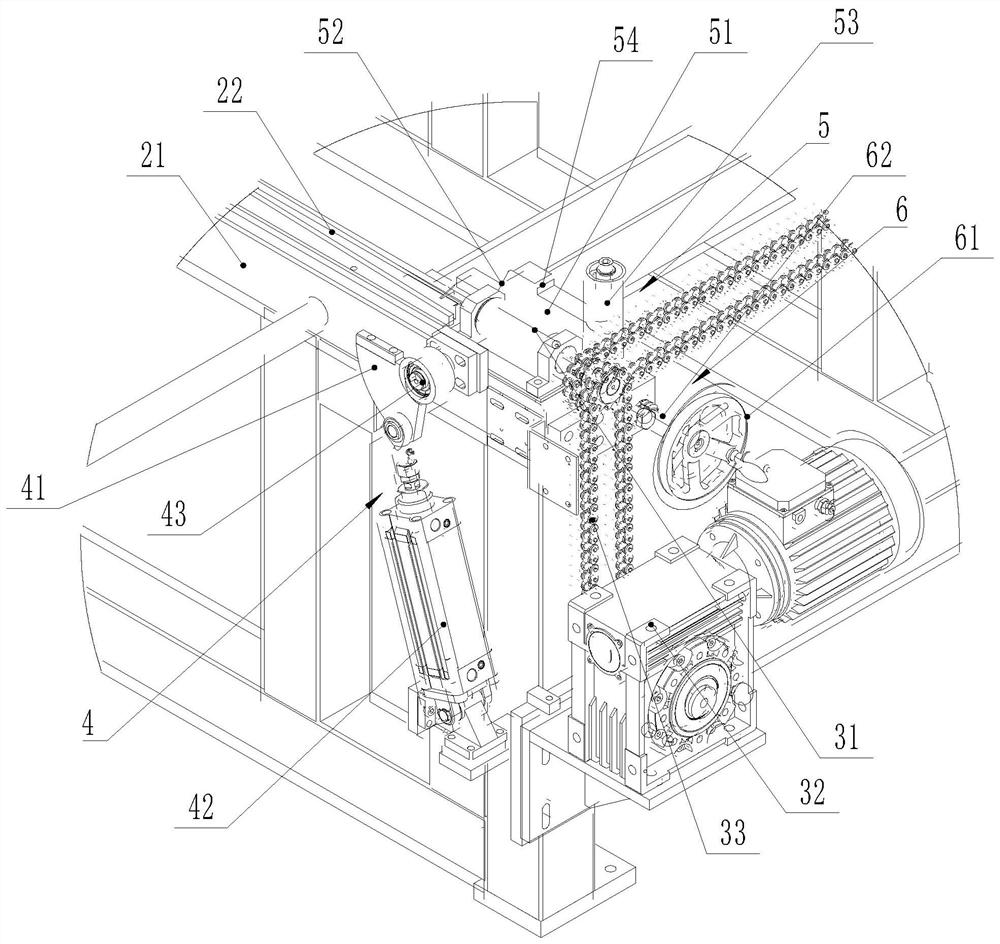

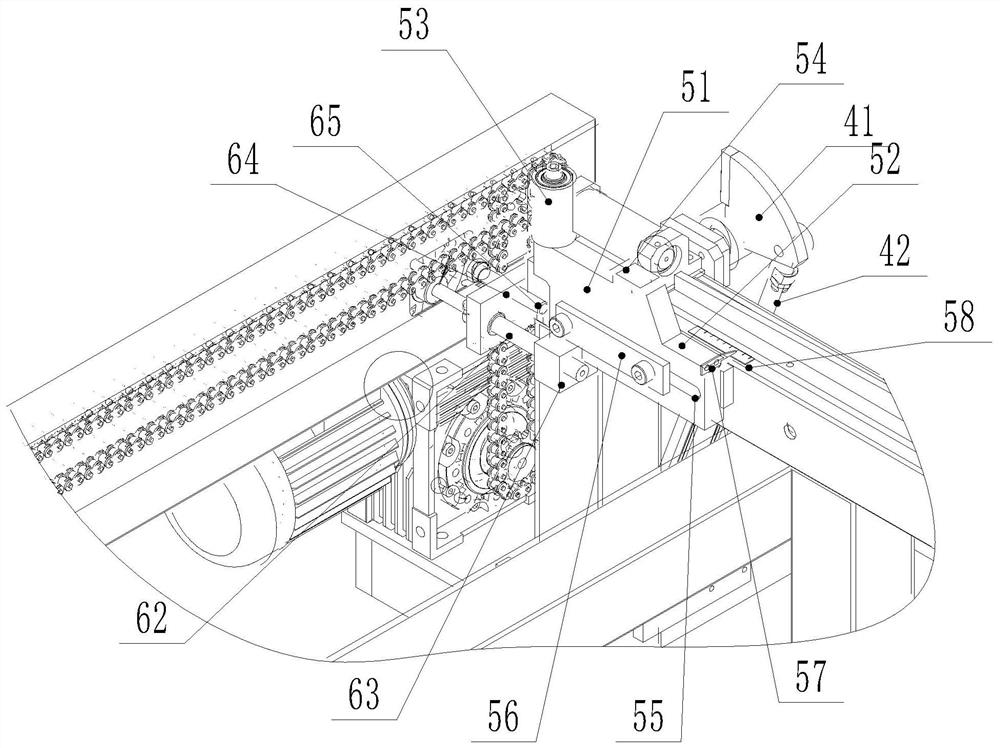

[0026] Such as Figure 1 to Figure 3 As shown, a material turning and conveying device of a short material sawing, cutting and drilling integrated machine includes a frame 1, and the frame 1 is provided with several supporting beams 2 for placing bars, and the supporting beams 2 The upper end of the upper end is provided with an inclined guide support surface that is convenient for bar rolling; in this embodiment, the support beam 2 includes a beam body 21 and a guide support plate 22, and the guide support plate 22 is detachably fixed on the beam body 21. The guide support surface is arranged on the guide support plate 22, and the guide support surface is T-shaped in cross section. By replacing the guide support plate 22, the guide support surface with different inclinations can be adjusted to meet the needs of bars of different sizes. Orientation requirements.

[0027]The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com