Tire vulcanization mold and tire manufacturing method

A technology for vulcanizing molds and tires, applied in the direction of tire tread/tread pattern, tire parts, tires, etc., can solve problems such as uneven rigidity and partial wear, and achieve the effect of restraining bending or breaking and restraining damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

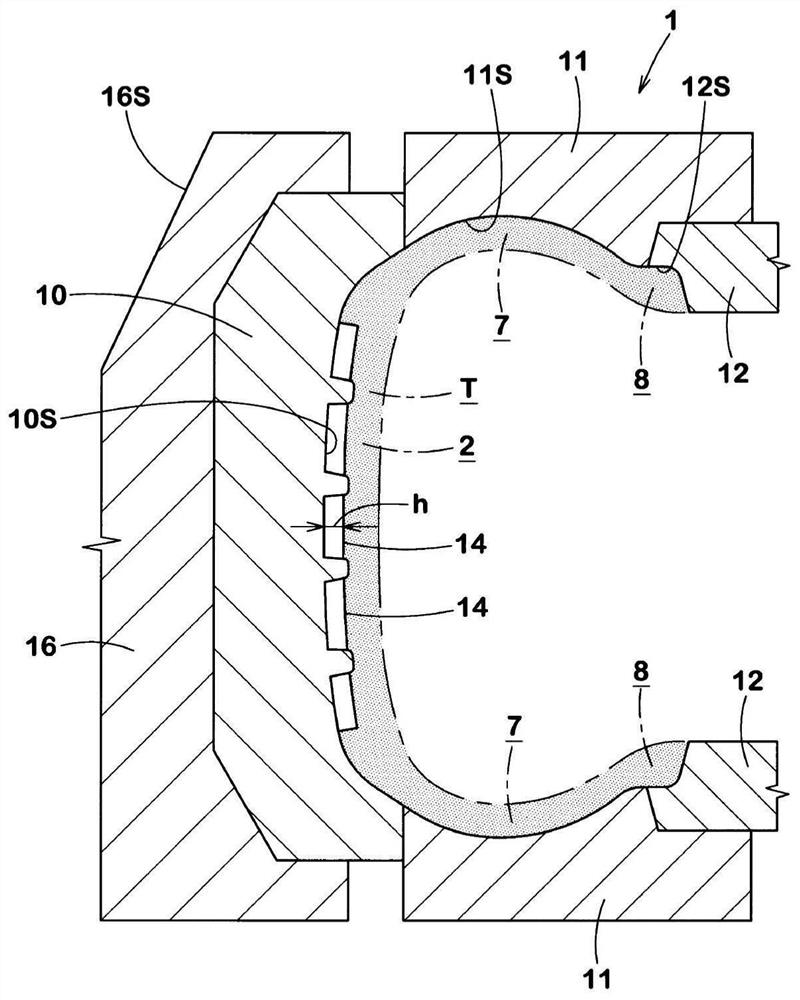

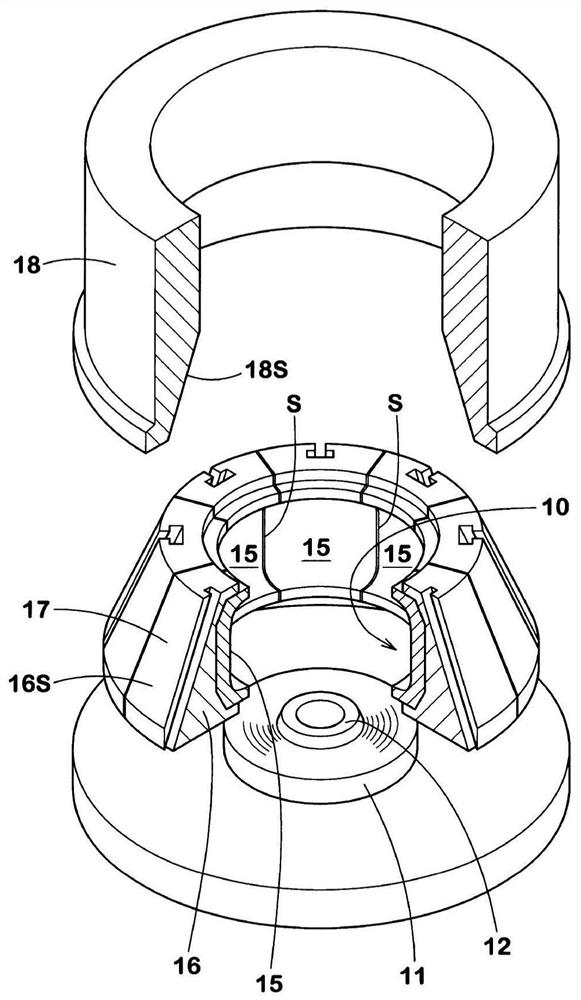

[0035] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

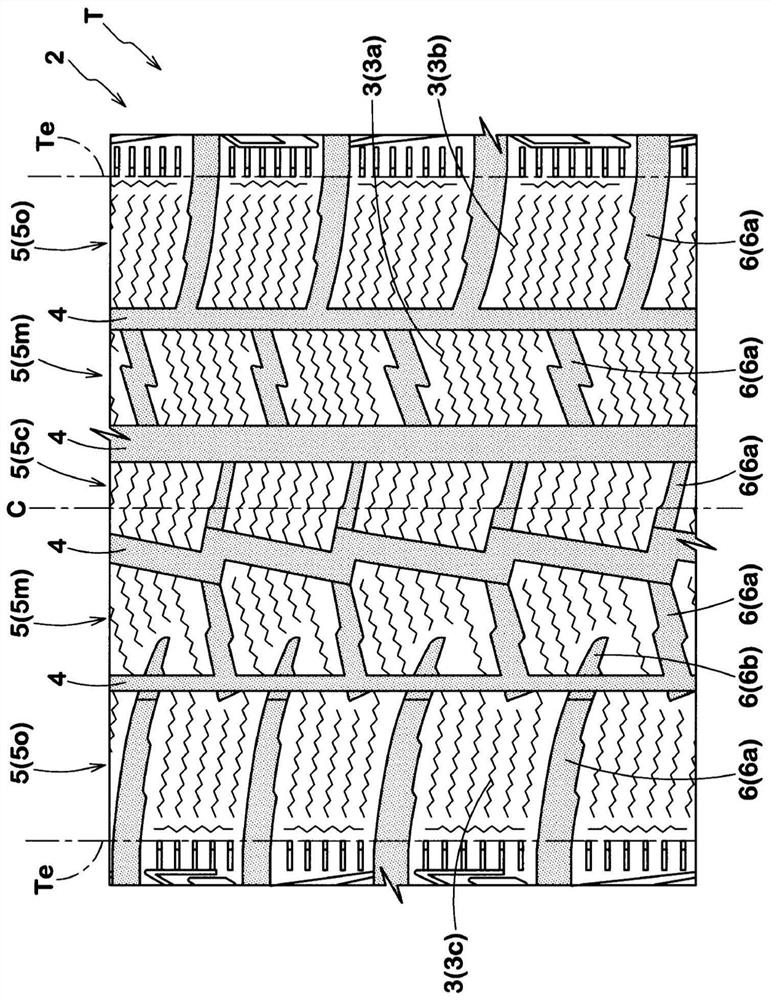

[0036] figure 1 Represent using vulcanization mold 1 of the present invention ( figure 2 Shown) is a developed view of the tread portion 2 of the manufactured tire T.

[0037] Such as figure 1 As shown, a plurality of sipes 3 arranged in the tire circumferential direction are arranged on the tread portion 2 . In this example, the tread portion 2 has a plurality of (for example, four) circumferential grooves 4 extending in the tire circumferential direction, and by the circumferential grooves 4, the tread portion 2 is divided into a plurality of (for example, four) extending in the tire circumferential direction. 5) Rib-shaped land part 5. In addition, a plurality of sipes 3 arranged along the tire circumferential direction are arranged on at least one rib-shaped land portion 5 (in this example, each rib-shaped land portion 5 ).

[0038] As the rib-shaped land p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com