Pharmacy department tablet powder grinding device

A pharmacy and tablet technology, which is applied in the field of pharmacy tablet grinding device, can solve problems such as inconvenient use and cleaning, lower grinding quality, inability to take medicine directly by mouth, and achieve improved friction, uniform vibration, and easy alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

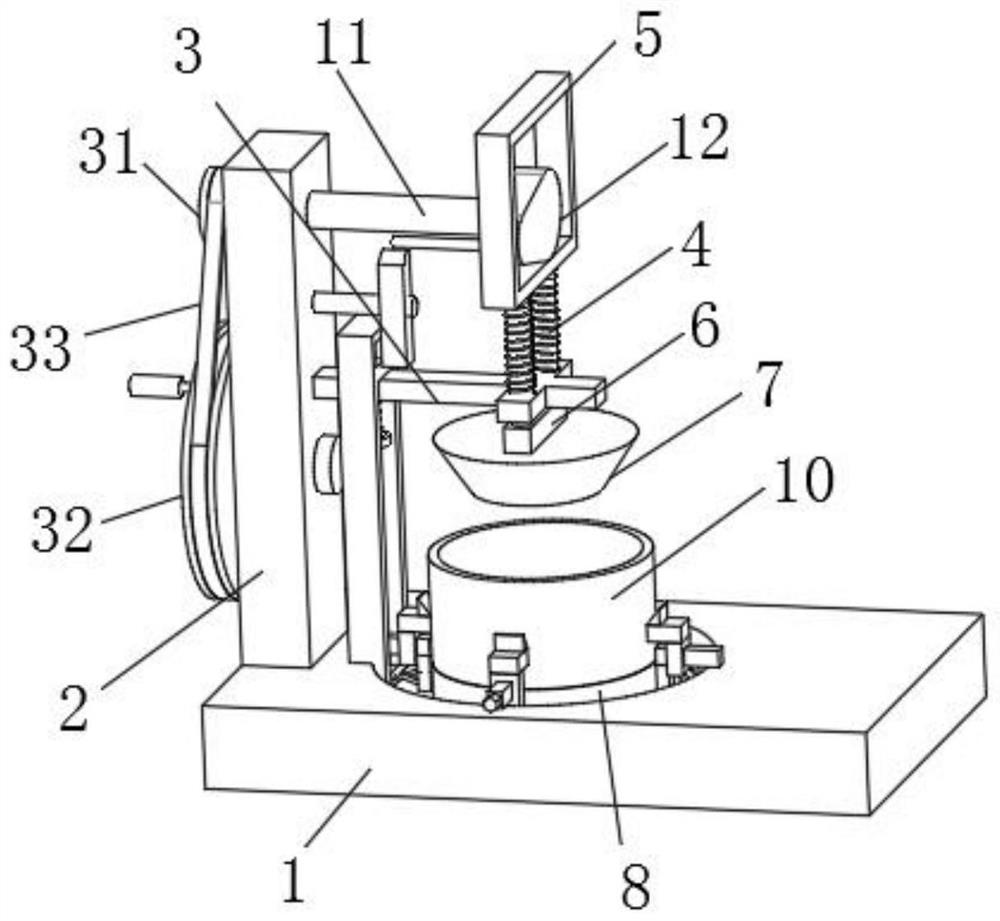

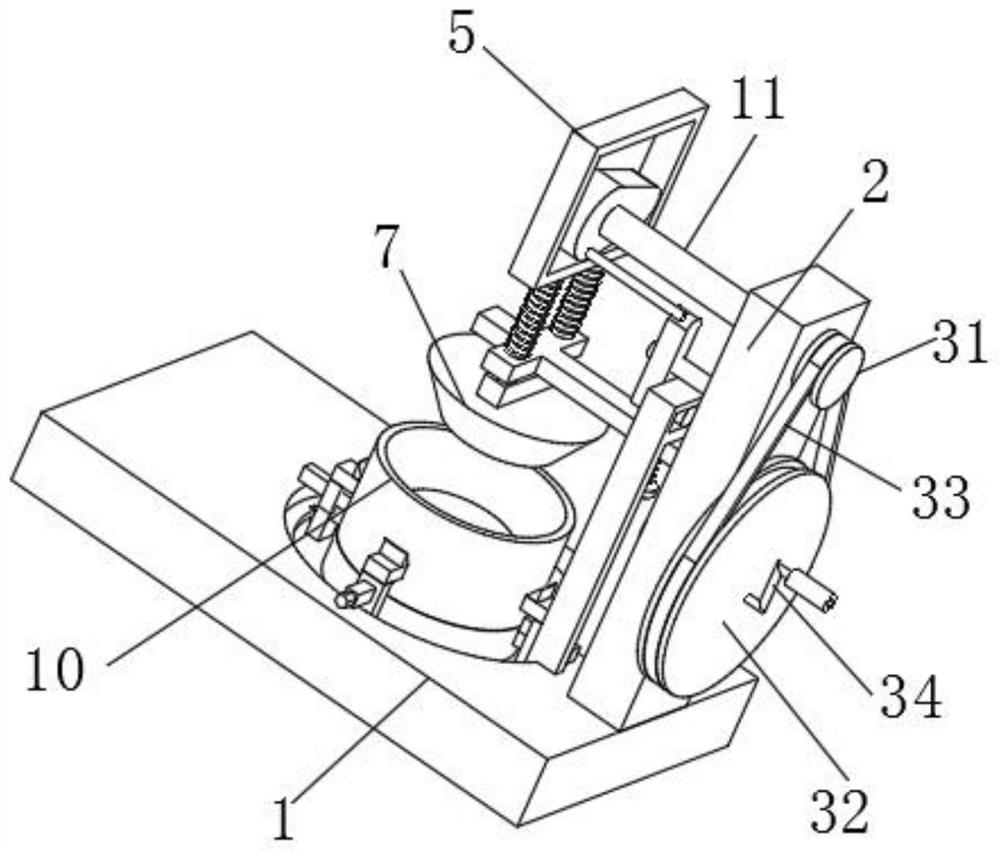

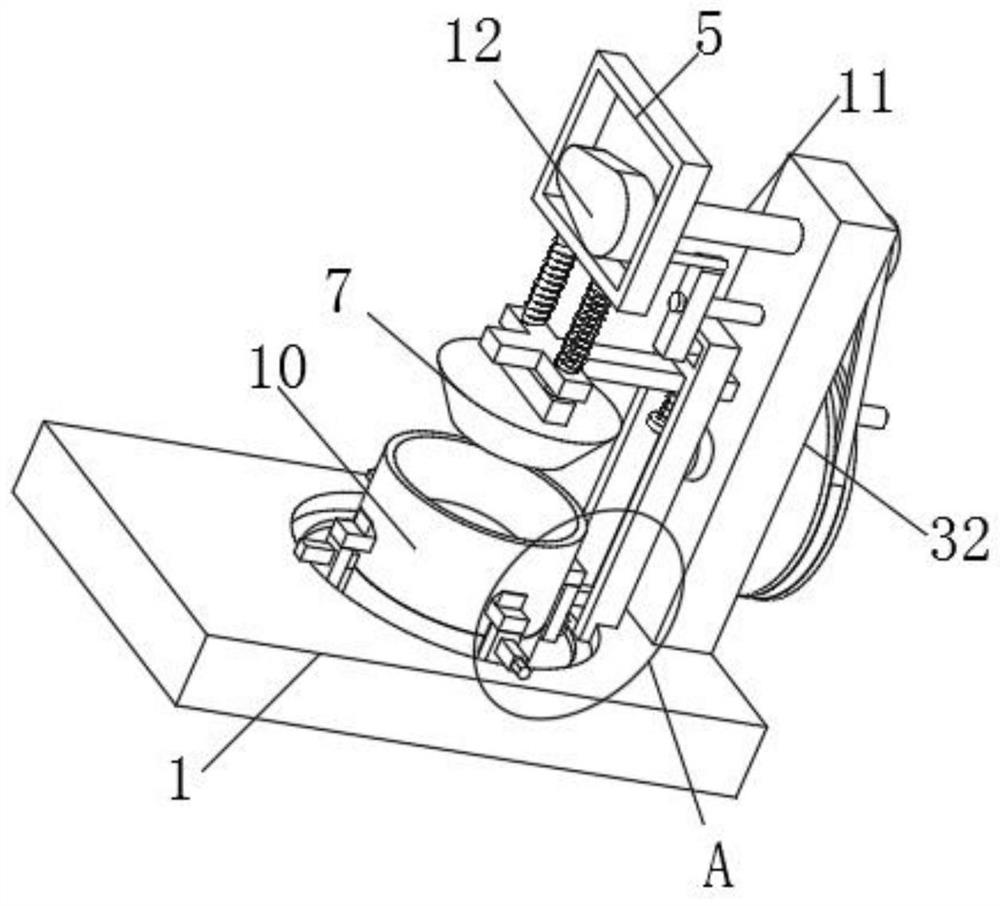

[0041] Example: Reference Figure 1-8 The pharmaceutical tablet grinding device shown includes a base 1, a support column 2 is fixedly installed on the top edge of the base 1, a T-shaped column 3 is fixedly installed in the middle of the side of the support column 2, and a T-shaped column 3 is fixedly installed on the top edge of the base 1. There are two guide holes on the top, and guide rods 4 are installed in the two guide holes. The bottom ends of the two guide rods 4 are fixedly installed with the same connecting block 6, and the bottom ends of the connecting block 6 are fixedly connected with the grinding head 7. Extrusion frame 5 is fixedly installed on the top of two guide rods 4, and one side of support column 2 is provided with rotating hole, and driving part is installed in the rotating hole, and driving part is connected with extruding frame 5, and the top of base 1 is provided with Fixed groove 28, the center position of the bottom side inner wall of fixed groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com