A kind of detection equipment for rare earth hydroxide washing with water

A detection equipment and technology of hydrogen oxidation, which are applied in the preparation of test samples, measuring devices, chemical instruments and methods, etc., can solve the problems of inability to conduct comprehensive detection, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

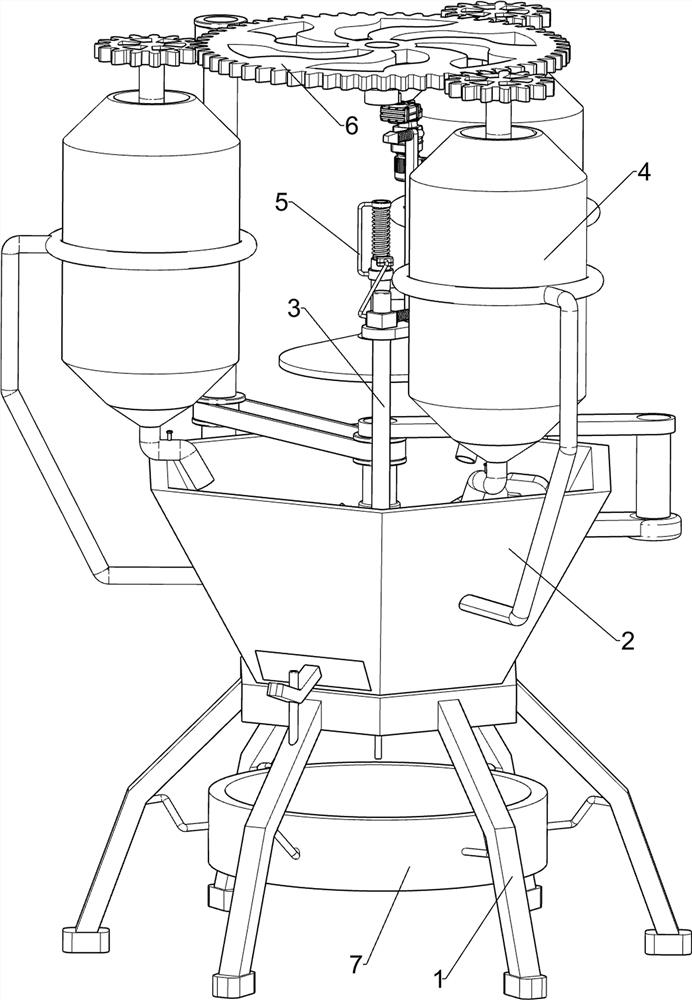

[0064] A detection equipment for rare earth hydroxide washing with water, such as figure 1 As shown, it includes a support 1 , a mixing mechanism 2 and an inspection mechanism 3 . The top of the support 1 is provided with a mixing mechanism 2 , and the mixing mechanism 2 is provided with an inspection mechanism 3 .

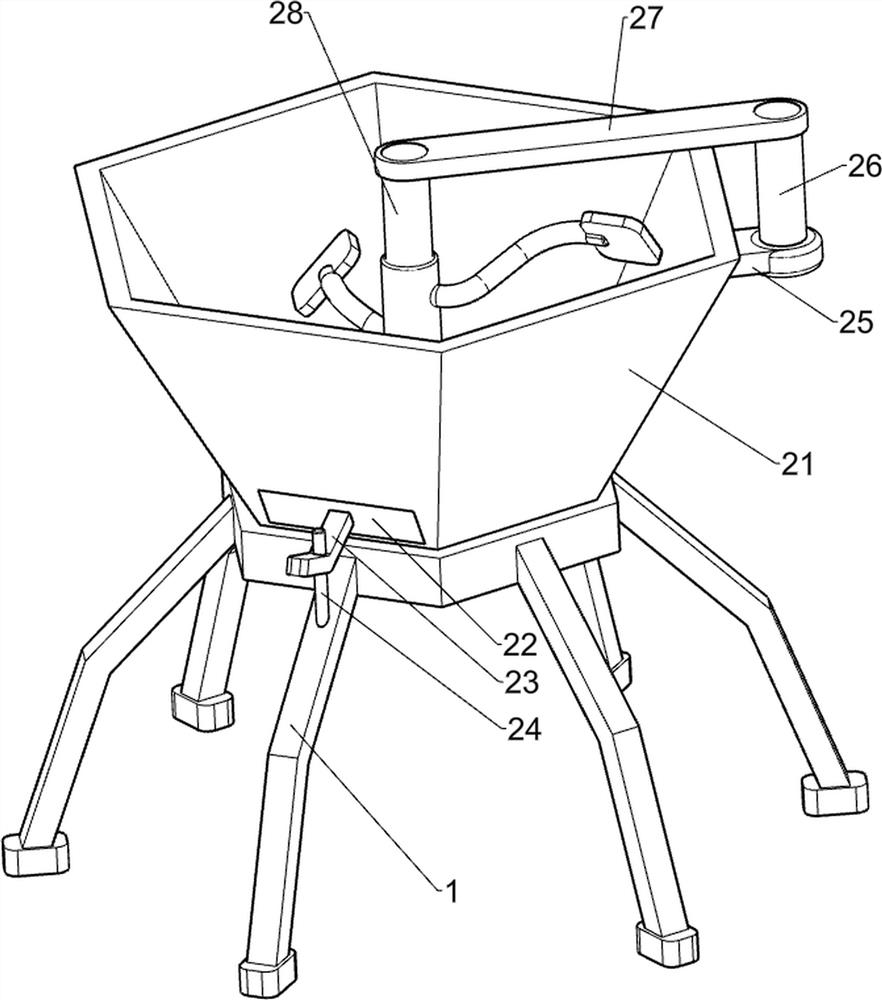

[0065] like figure 2 As shown, the mixing mechanism 2 includes a mixing box 21, a valve 22, an ejector rod 23, a first fixing rod 24, a first mounting block 25, a second fixing rod 26, a first mounting rod 27 and a first stirring rod 28. The bracket 1. The top is provided with a mixing box 21 that can be manually controlled for unloading. The mixing box 21 is provided with a sliding valve 22 on the front left side. , the first fixing rod 24 cooperates with the ejector rod 23, the right side of the mixing box 21 is provided with a first mounting block 25, the top of the first mounting block 25 is provided with a second fixing rod 26, and the upper side of the sec...

Embodiment 2

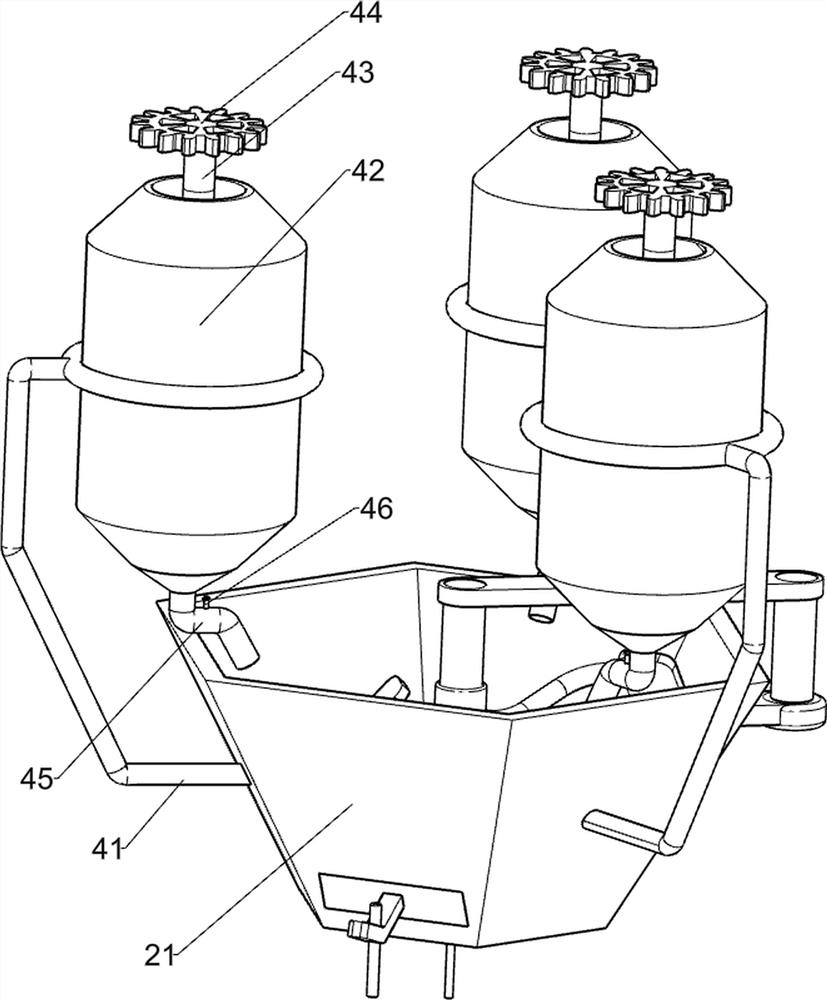

[0069] On the basis of Example 1, as Figure 4 As shown, it also includes a feeding mechanism 4. The feeding mechanism 4 includes a feeding rod 41, a feeding box 42, a second stirring rod 43, a first gear 44, a guide rod 45 and a first switch 46. The mixing box The outer side of 21 is evenly provided with three unloading rods 41, the unloading rods 41 are all provided with unloading boxes 42, the second stirring rods 43 are rotatably arranged in the unloading boxes 42, and the upper sides of the second stirring rods 43 are all provided with The first gear 44 and the bottom of the unloading box 42 are provided with guide rods 45 , and the guide rods 45 are all provided with a first switch 46 .

[0070] The staff first pours the same amount of rare earth to be detected into the unloading box 42, and then rotates the first gear 44, the rotation of the first gear 44 drives the rotation of the second stirring rod 43, and the rotation of the second stirring rod 43 can perform prelim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com