Paint spraying mechanical equipment

A kind of mechanical equipment, spraying technology, applied in the direction of construction, building structure, etc., can solve the problems of uneven wall coating, low degree of automation, low painting efficiency, etc., to improve painting efficiency, high degree of automation, high adjustment effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

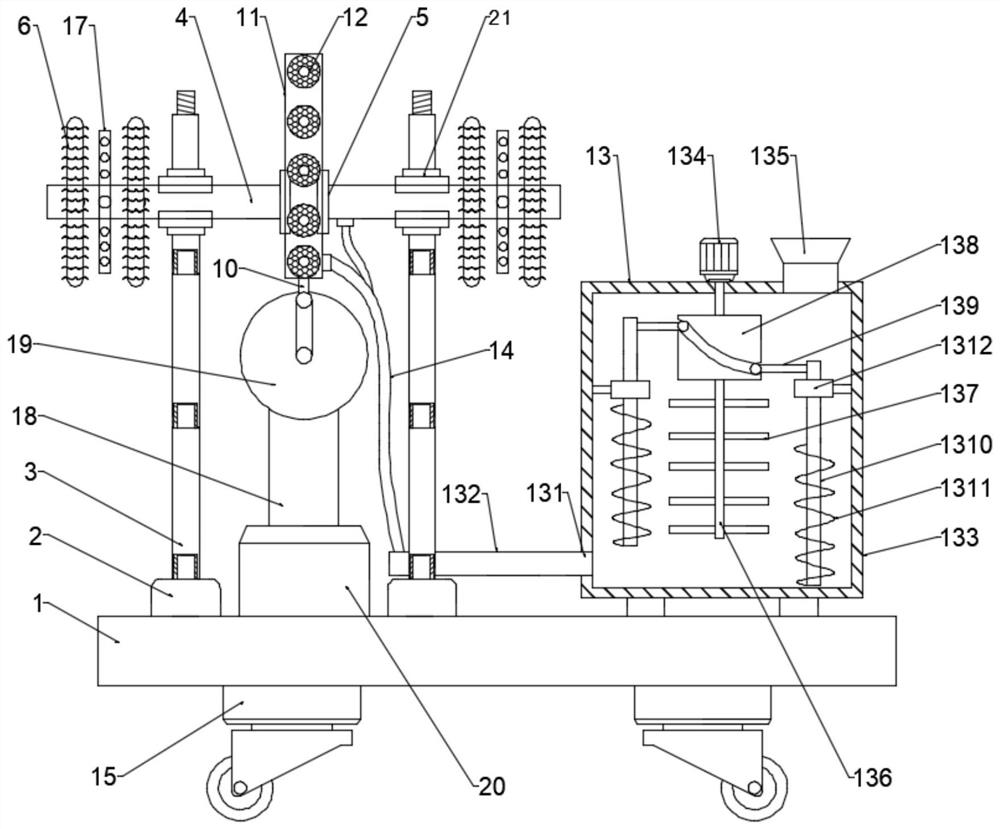

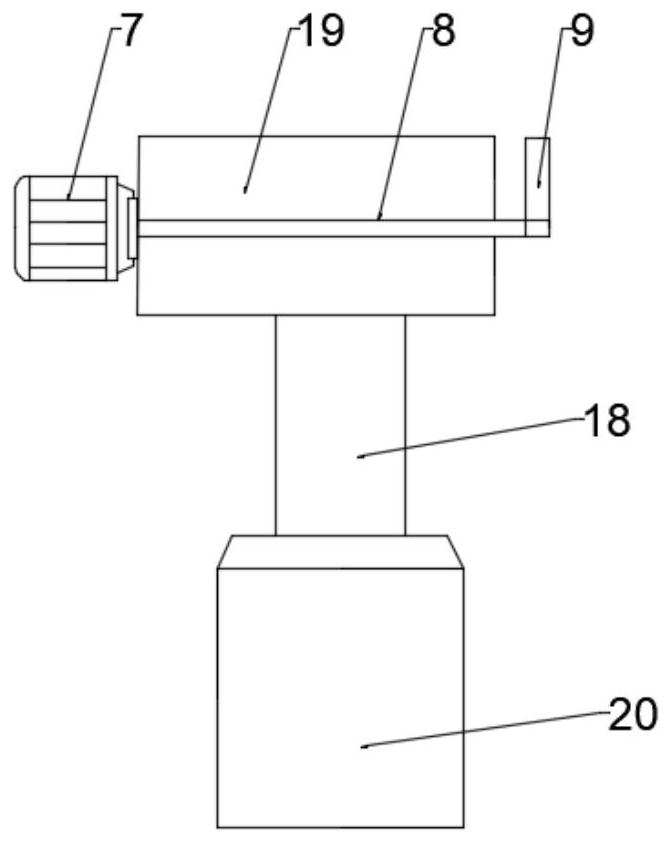

[0025] see figure 1 and 2 , in the embodiment of the present invention, a paint spraying mechanical equipment, including a base 1, two support bases 2 are installed on one side above the base 1, a slide rail 3 is arranged above the support base 2, and the slide rails 3. A first clamping seat 21 is slidably connected, and the first sliding plate 4 is slidably clamped on the first clamping seat 21, so that the first sliding plate 4 can move left and right in the first clamping seat 21. The center of the first sliding plate 4 is provided with a second clamping seat 5, and the left and right sides of the second clamping seat 5 are symmetrically equipped with the first painting device 6, and the middle of the support base 2 is provided with a hydraulic machine base 20, through which 20 The heights of the first painting device 6 and the second painting device 12 can be adjusted according to the height of the construction wall. A hydraulic rod 18 is connected above the hydraulic mac...

Embodiment 2

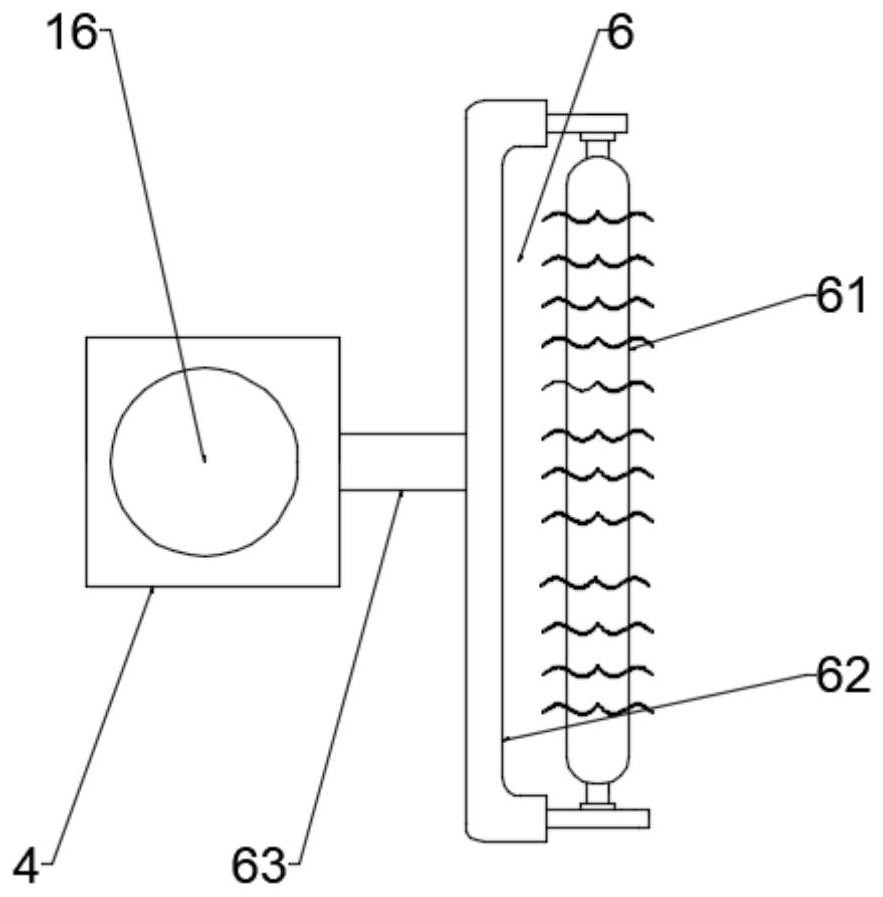

[0030] see image 3 , in this embodiment, the first painting device 6 includes a painting post 61, on which bristles are evenly distributed, and the upper and lower sides of the painting post 61 are hinged with a painting frame 62, and the painting frame 62 passes through a pole 63 is fixedly connected with the first sliding plate 4, and the length of the pole 63 is greater than the height of the first clamping seat 21, so that the first painting device 6 is fixed while avoiding the interference between the painting frame 62 and the first clamping seat 21.

[0031] see Figure 4 , in this embodiment, the second painting device 12 includes a painting plate 121 evenly arranged on the surface of the second sliding plate 11, and a spraying tube 122 is arranged at the center of the painting plate 121, and the spraying tube 122 is connected to the first The spraying device 16 inside the two sliding plates 11 is in communication.

Embodiment 3

[0033] In this embodiment, the stirring device 13 includes a stirring box 133, a rotating motor 134 is arranged on the top of the stirring box 133, a feeding port 135 is arranged on one side of the rotating motor 134, and a connection is made under the rotating motor 134. There is a stirring shaft 136 with a plurality of stirring rods 137 arranged circumferentially.

[0034]In this embodiment, a cylindrical cam 138 is installed on the upper part of the stirring shaft 136, and movable rods 139 are slidably connected to the chute on both sides of the cylindrical cam 138, and the movable rod 139 is fixedly connected to a lifting column 1310, and the lifting column 1310 A spiral stirring blade 1311 is installed below, and the upper part of the lifting column 1310 is slidably connected with a limit sleeve 1312, and the limit sleeve 1312 is fixedly connected with the inner wall of the stirring box 133 through a fixed rod; the stirring shaft 136 drives the cylinder when rotating The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com