Clean stirring device for making spicy red oil

A technology of spicy red oil and stirring device, which is applied in the direction of mixer with rotating stirring device, mixer accessories, dissolving, etc., which can solve the problems of difficult cleaning of oil stains, adhesion, and inconvenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

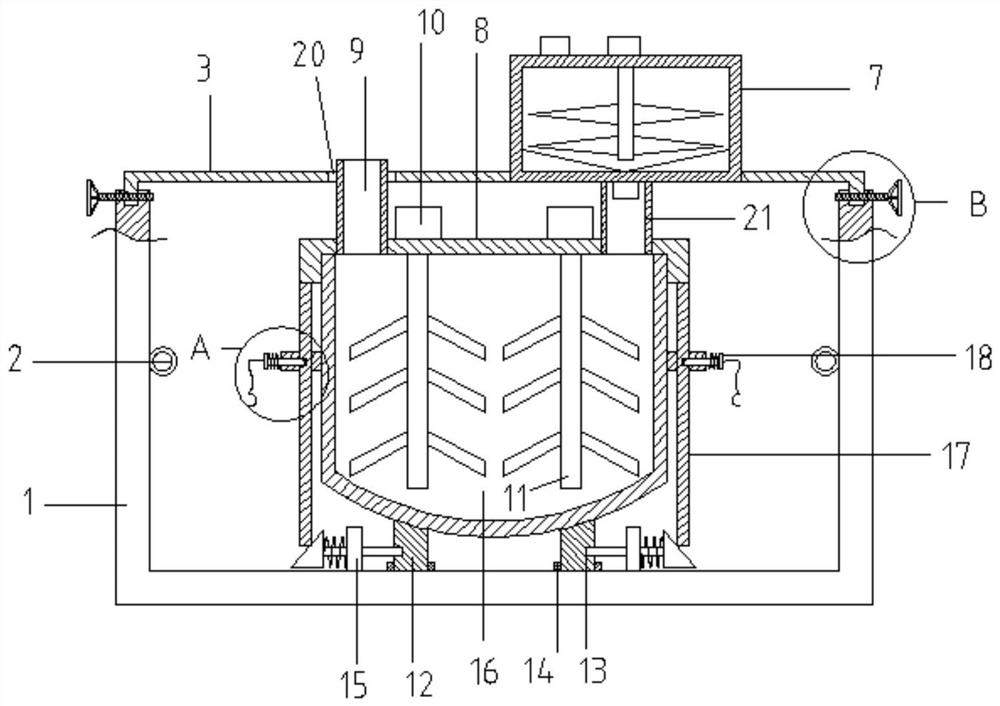

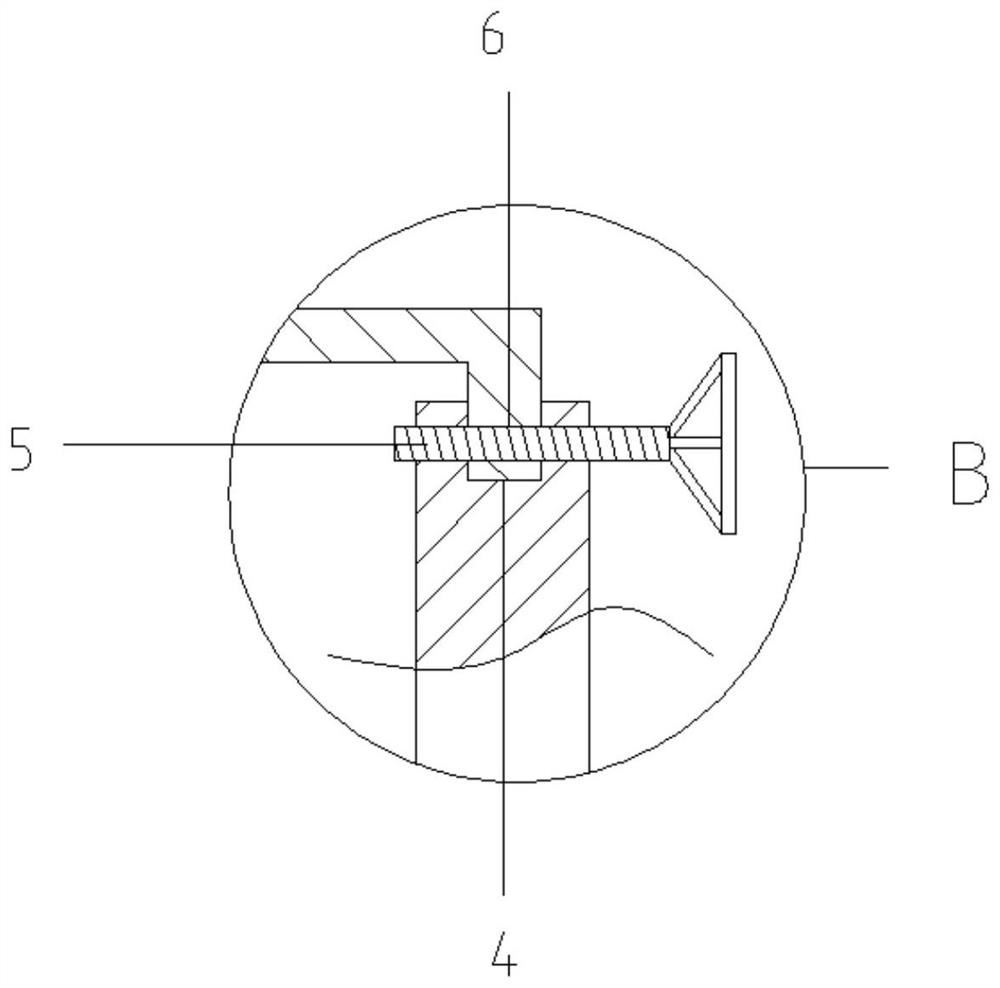

[0028] The invention provides a technical solution: a clean stirring device for making spicy red oil, comprising a U-shaped base 1, the bottom of the U-shaped base 1 is provided with a non-slip mat, and the inner side of the U-shaped base 1 is symmetrically fixed with a ring 2 The upper end of the U-shaped base 1 is symmetrically provided with a groove 4, and the inner side of the two grooves 4 is clamped to be provided with a U-shaped frame 3, and both sides of the U-shaped frame 3 are provided with threaded holes 6, and the two sides of the U-shaped frame 3 The side symmetry screw is connected with screw rod 5, and the outer end of screw rod 5 is fixed with changing hands, and screw rod 5 is threadedly connected with threaded hole 6, and the upper end left side of U-shaped frame 3 is provided with through hole 20, and the upper end right side of U-shaped frame 3 is provided with The crushing assembly 7, the upper end of the bottom plate of the U-shaped base 1 is symmetrically...

Embodiment 2

[0031] Based on the clean stirring device for making spicy red oil provided in Embodiment 1 of the present application, Embodiment 2 of the present application proposes another clean stirring device for making spicy red oil. Embodiment 2 is only a further form of Embodiment 1, and the implementation of Embodiment 2 will not affect the implementation of Embodiment 1 alone.

[0032] Embodiment 2 of the present invention will be further described below in conjunction with the accompanying drawings and implementation methods.

[0033] Compared with Embodiment 1, this embodiment provides a specific crushing assembly 7 including a crushing box 71, a crushing motor 72, a crushing rod 73, a feed pipe 74, a lower hopper 75 and a discharge pipe 76, and the crushing box 71 is inserted Connected and fixed on the U-shaped frame 3, a pulverizing motor 72 is installed on the pulverizing box 71, the output shaft of the pulverizing motor 72 runs through the pulverizing box 71 and is connected ...

Embodiment 3

[0035] Based on the clean stirring device for making spicy red oil provided in Embodiment 1 of the present application, Embodiment 3 of the present application proposes another clean stirring device for making spicy red oil. Embodiment 3 is only a further form of Embodiment 1, and the implementation of Embodiment 3 will not affect the implementation of Embodiment 1 alone.

[0036] Embodiment 3 of the present invention will be further described below in conjunction with the accompanying drawings and implementation methods.

[0037] Compared with the first embodiment, this embodiment provides a specific limiting component 1 18 and a limiting component 2 15 .

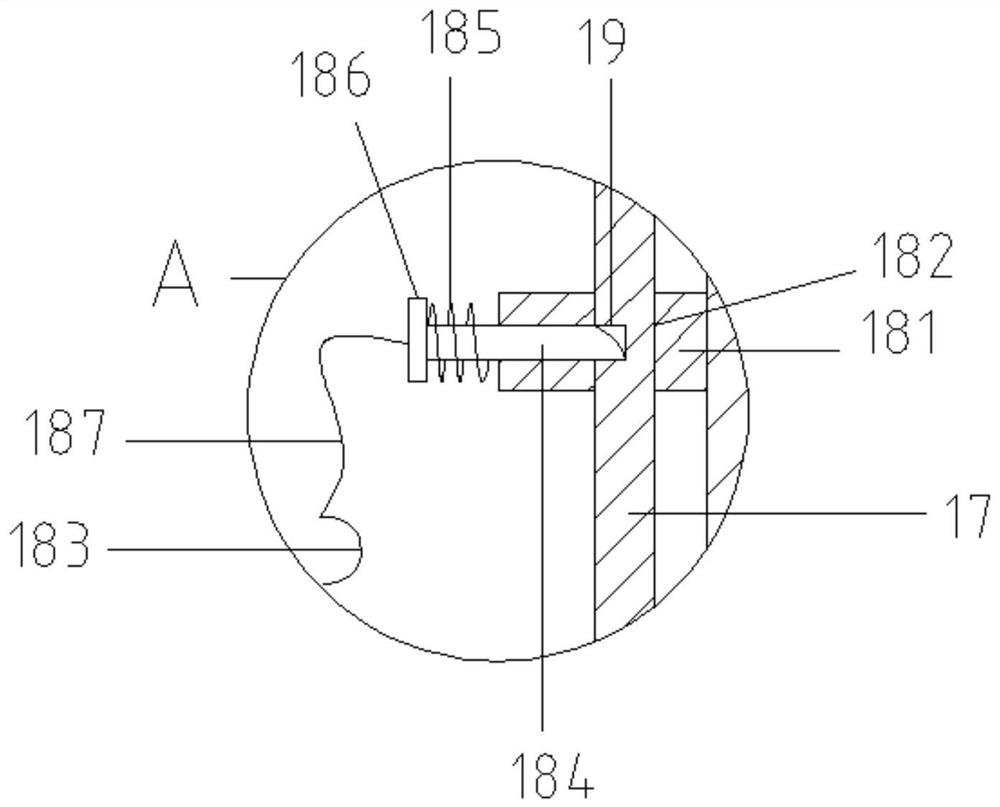

[0038]Limiting assembly one 18 comprises rectangular block 181, circular hole 182, hook 183, clamp bar 184, spring one 185, strip plate 186 and connecting rope 187, and rectangular block 181 is fixedly connected with mixing tank 16, and rectangular block 181 is provided with Circular hole 182, on the rectangular block 181...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com