External circulation ammonification reactor

A technology of ammonification reactor and external circulation, which is applied in the field of phosphorus and ammonia production, which can solve the problems of hindering gas-liquid two-phase mass transfer reaction, clogging of distributor orifice, and uneven distribution of gas and liquid, so as to improve the pipeline blocked by slurry , the reduction of slurry impurities, and the effect of reducing the probability of slurry blocking the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

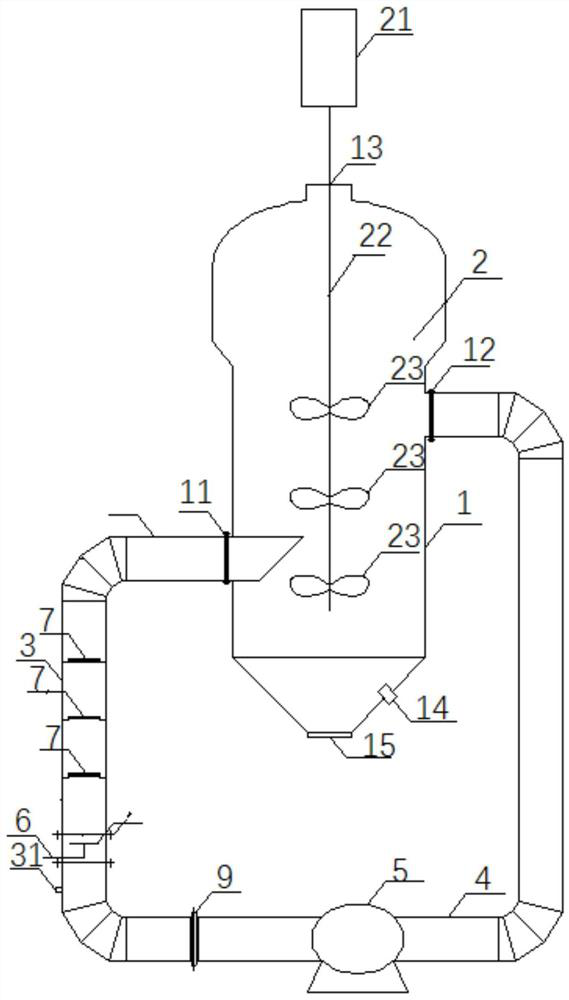

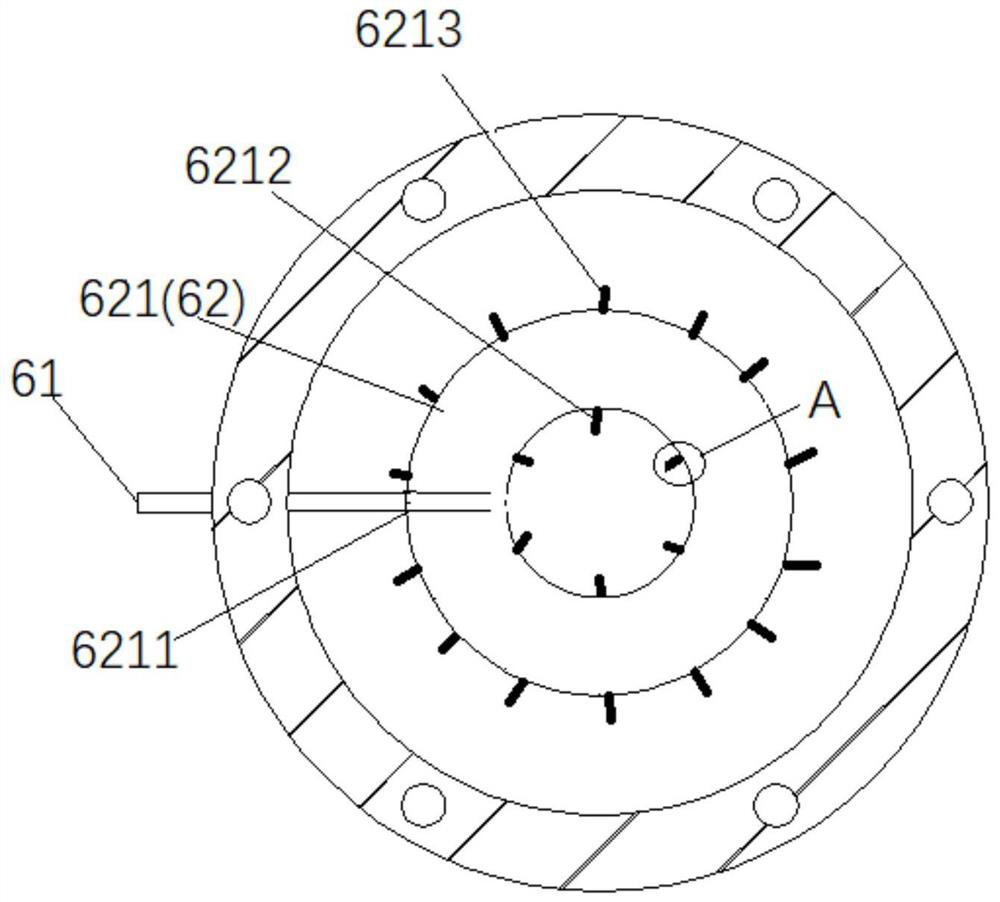

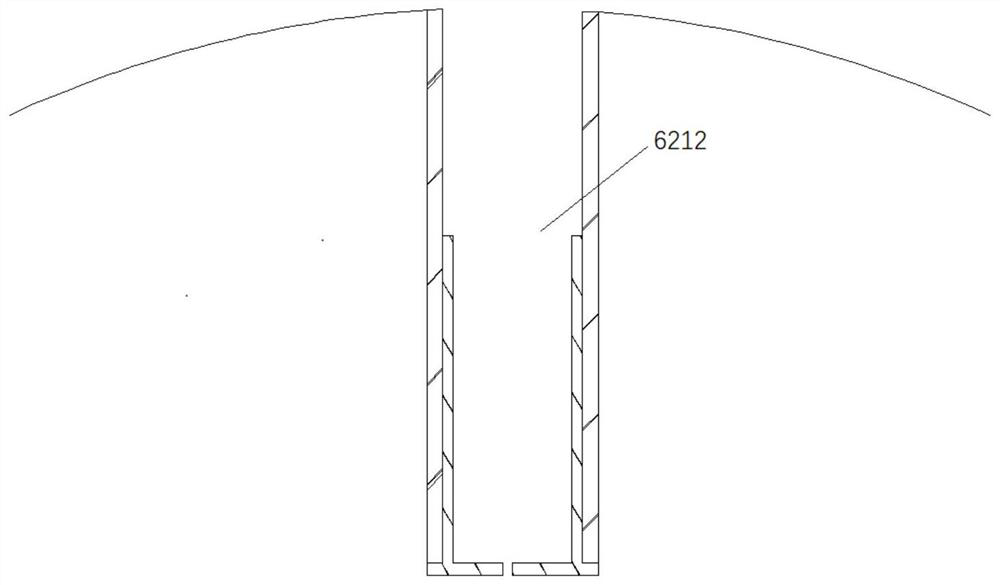

[0026] Such as figure 1 As shown, a kind of outer loop ammoniation reactor of the present invention comprises a settling separator 1, a stirring device 2, a riser 3, a return pipe 4, a circulation pump 5, a gas distributor 6 and a plurality of grids 7;

[0027] The settling separator 1 is provided with a circulation inlet 11 and a circulation outlet 12 which communicate with the interior thereof. One end of the return pipe 4 communicates with the liquid inlet of the circulation pump 5, and the other end communicates with the circulation outlet 12. One end of the riser pipe 3 communicates with the liquid inlet of the circulation pump 5. The liquid outlet of the circulation pump 5 is connected, and the other end is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com