For device for the dust removal of the turntable gas

A gas dust removal and converter technology, which is applied in the field of devices for dust removal of converter gas, can solve problems such as speed peaks, damage filter elements, shorten filter life, etc., and achieve the effects of reducing explosion risk and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

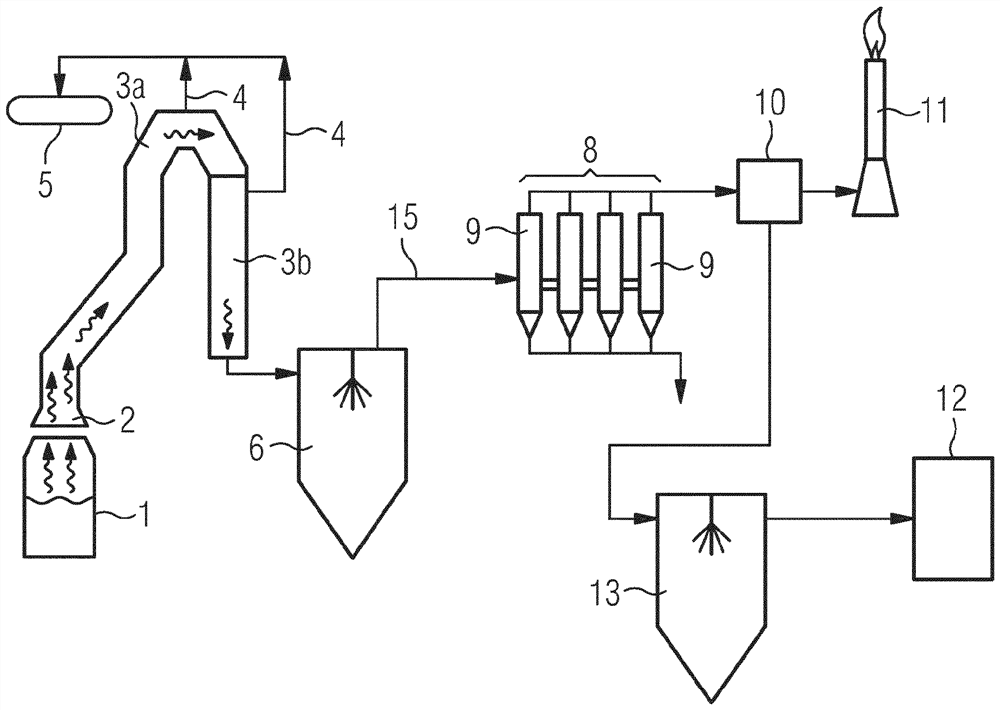

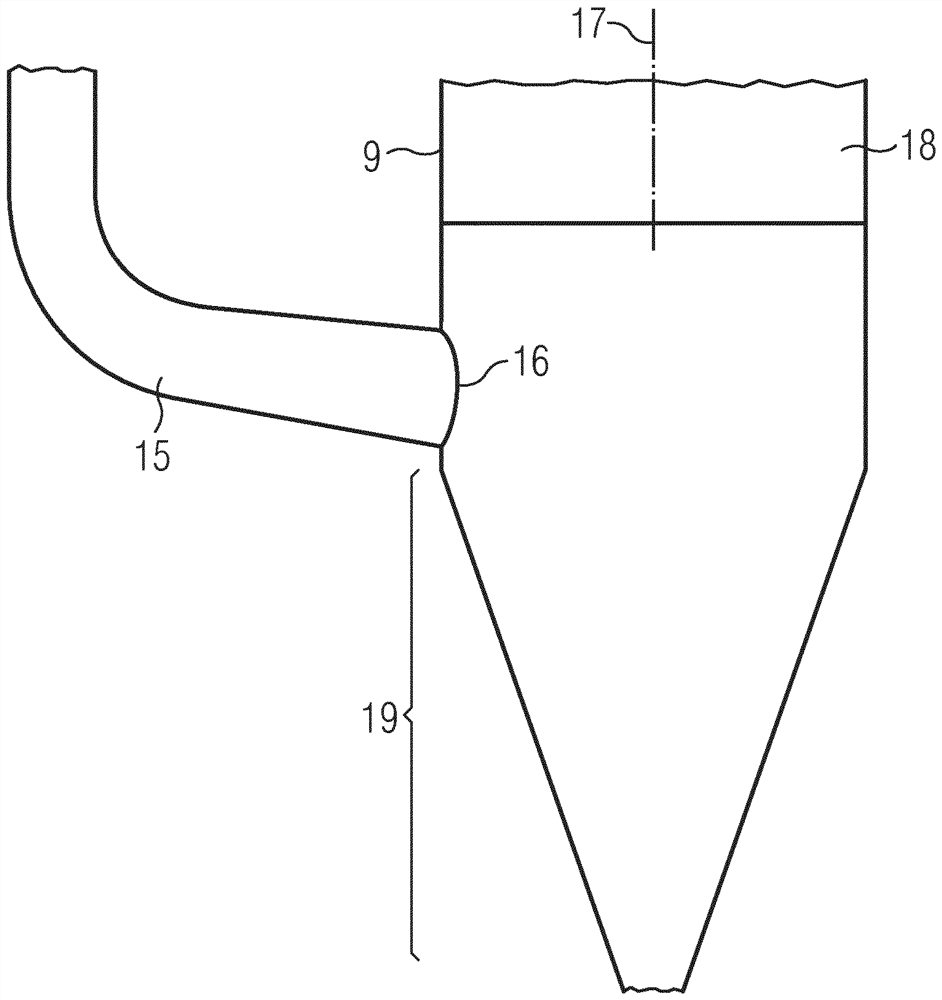

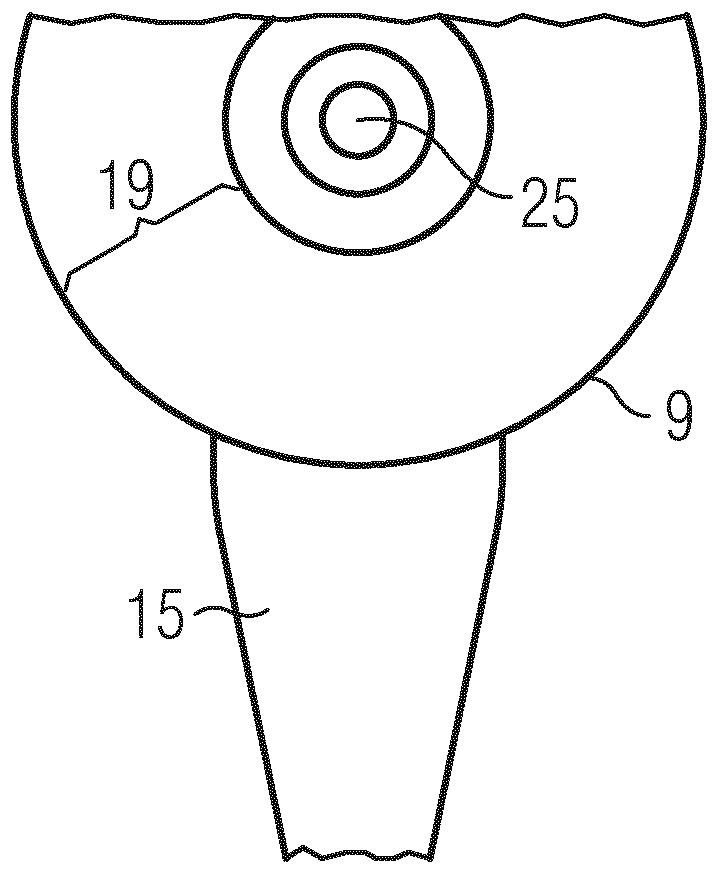

[0053] figure 1 One possible plant for the treatment of converter gases is shown and the basic sequence is explained. The device according to the invention replaces the figure 1 The device 8 for dedusting shown in is installed.

[0054] exist figure 1The converter gas rises from the converter 1 into the hood 2, which is shown by the corrugated arrows. By means of the hood, in the case shown, the converter gases are conducted with steam generation into the cooling chimney, which is the first cooling device for indirect cooling. The cooling chimney includes cooling chimney pieces 3a and 3b. The steam produced by the heat exchange between the converter gas and the cooling medium water guided in pipes not shown in the cooling chimney is led to the steam drum 5 via the pipe 4 . In the cooling stack, a first cooling step is carried out for the converter gas by means of indirect cooling by means of water / steam. At the end of the cooling chimney 3a, the converter gas has a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com