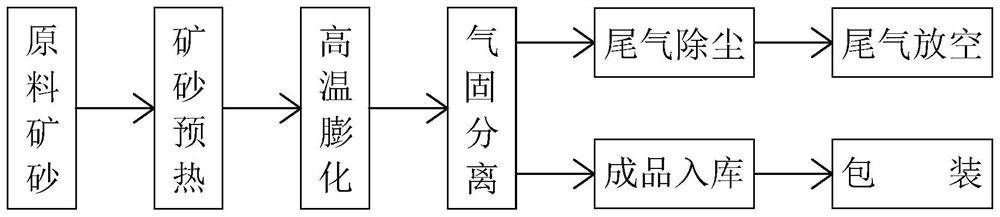

Inorganic light aggregate spray cooling system and inorganic light aggregate direct spray cooling method

A lightweight aggregate and inorganic technology, which is applied in the field of inorganic lightweight aggregate spray cooling system, can solve the problems of insufficient cooling, shedding of product particle skin, and direct crushing of particles, so as to reduce heat load, high product quality, reduce The effect of particle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

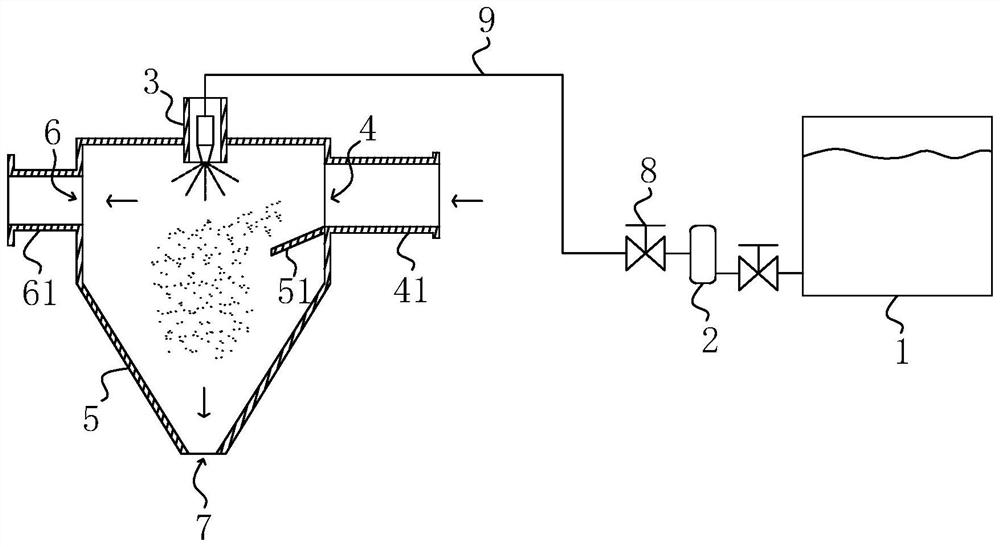

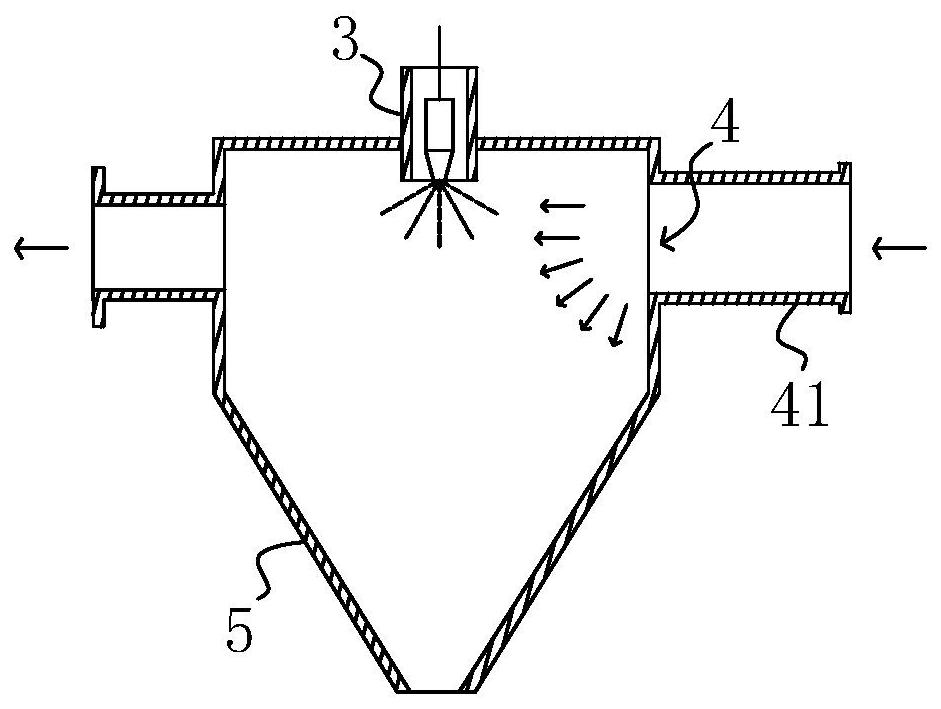

[0041] An inorganic light aggregate spray cooling system, refer to figure 2 , which includes a gas-solid separation device 5 with a cylindrical body and a funnel-shaped bottom. The cylindrical main body of the gas-solid separation equipment 5 is provided with a material inlet 4 and an exhaust gas outlet 6, and a finished product outlet 7 for discharging the separated finished inorganic lightweight aggregate is opened at the bottom end. The material inlet 4 is connected with a material inlet pipe 41 , and the waste gas outlet 6 is connected with an exhaust gas outlet pipe 61 . The inorganic lightweight aggregate is conveyed by pneumatic force, and enters the gas-solid separation equipment 5 through the material inlet pipe 41 and the material inlet 4; after the inorganic lightweight aggregate particles settle in the gas-solid separation equipment 5, they are discharged from the finished product outlet 7, and the dust-laden waste gas is discharged from the gas-solid separation e...

Embodiment 2

[0048] A kind of inorganic light aggregate direct spray cooling method, it is based on embodiment 1, specifically comprises the following steps:

[0049] Step 1: The inorganic light aggregate to be cooled is introduced into the gas-solid separation equipment 5 of the inorganic light aggregate spray cooling system in Example 1 through the material inlet pipe 41 by means of pneumatic conveying.

[0050] Step 2: Open the valve 8 and the metering pump 2, use the pipeline 9 to pass the clean water in the water tank 1 into the spray device 3, and spray the water mist to the inner space of the gas-solid separation equipment 5. In order to ensure the spray effect, the spray device 3 selects a hydraulic direct-injection nozzle, and the particle size of the sprayed water mist droplets is controlled to be less than or equal to 300 μm by adjusting the pressure of the nozzle. The mass ratio of the spray amount to the inorganic lightweight aggregate is controlled at 0.1:1-1:1, and the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com