Device for removing dust from converter gas

A technology for gas dust removal and converter, which is applied in the field of devices for dust removal of converter gas, can solve problems such as speed peaks, damage filter elements, increase load, etc., and achieve the effects of improving compressive strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

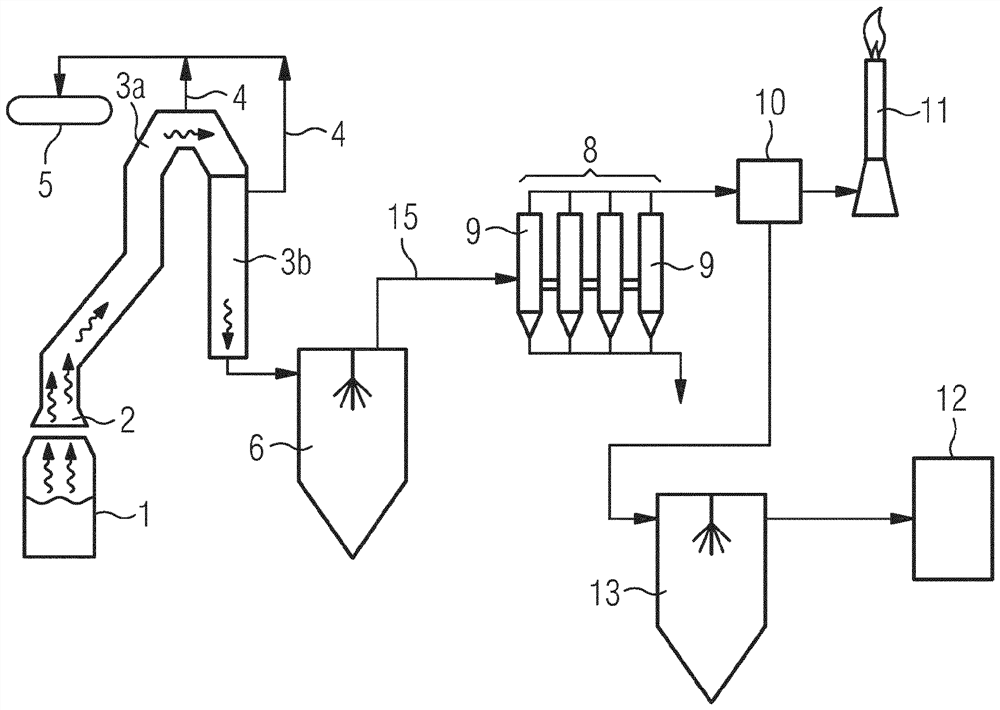

[0053]figure 1 A possible device for processing the converter gas is shown and the basic flow will be described. The apparatus according to the present invention is replacedfigure 1 The device 8 shown in the presence is mounted.

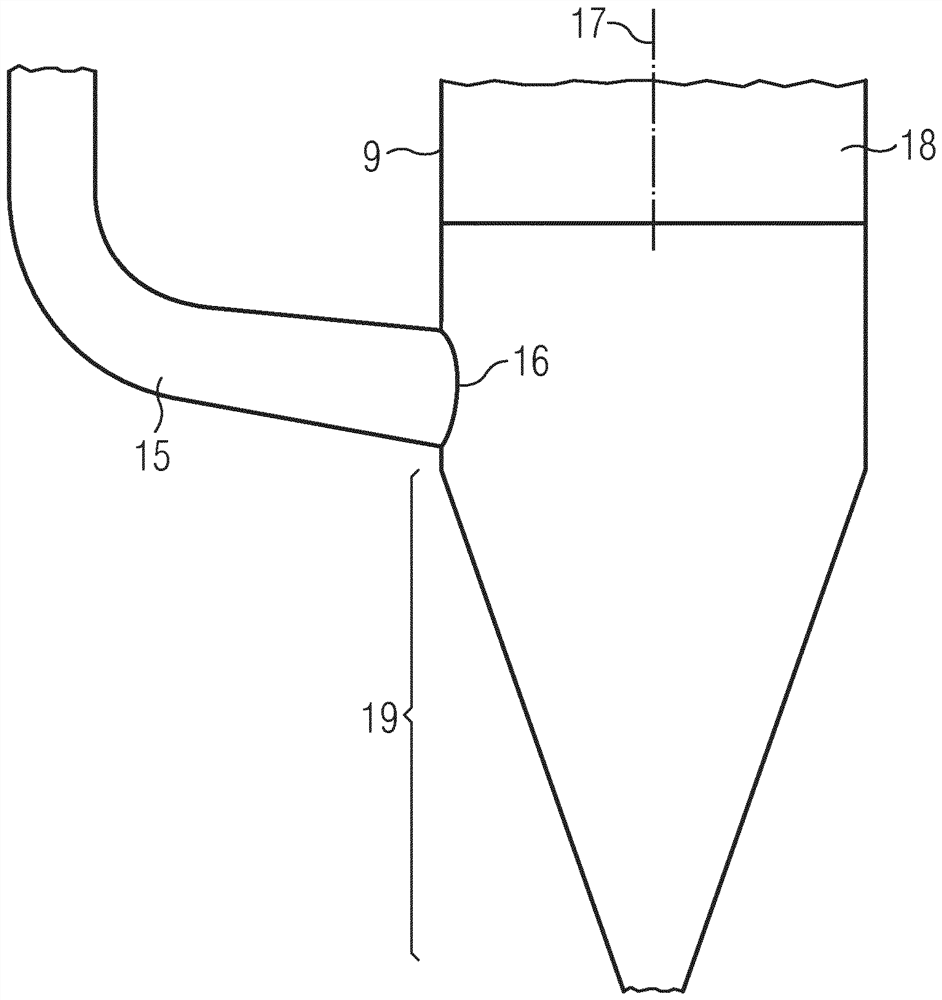

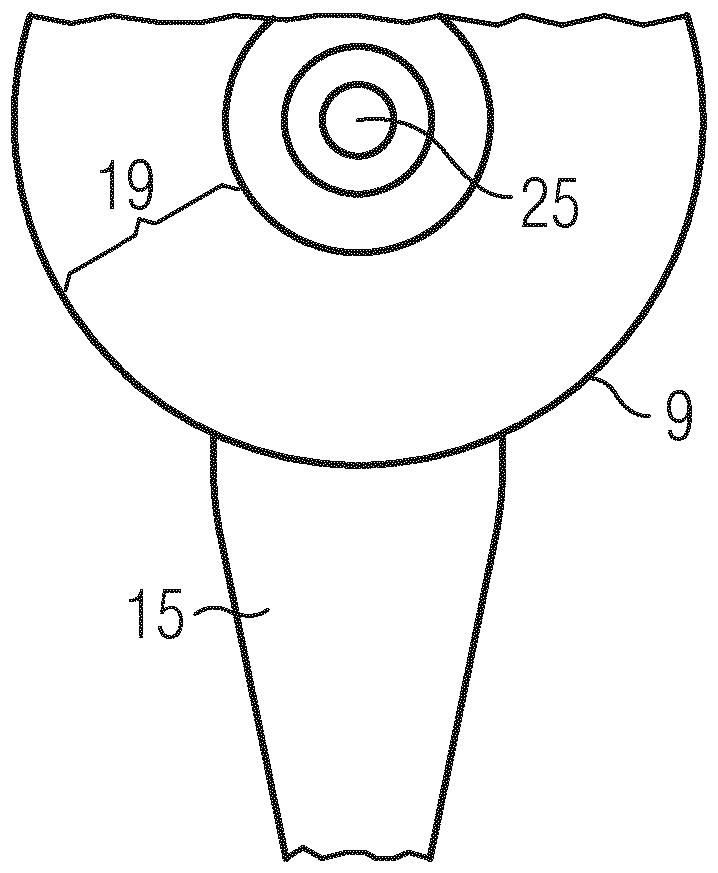

[0054]infigure 1 The medium transfer furnace gas rises from the converter 1 to the envelope 2, which is shown by a corrugated arrow. The converter gas is directed to the cooling chimney by the shield in the case where steam is generated, the cooling chimney is a first cooling device for performing indirect cooling. The cooling chimney includes a cooling of the smoke 3a and 3b. The steam generated between the heat exchange between the cooling medium water obtained by the converter gas and the tube of the cooled chimney is introduced is directed to the vapor 5 via the conduit 4. In the cooling chimney, the first cooling step is performed for the converter gas by indirect cooling by water / vapor. At the end of the cooling chimney member 3a, the converter gas ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com