A topology of high-power charging device based on three-level rectifier

A technology of three-level rectification and high-power charging, which is applied in the direction of output power conversion device, irreversible AC power input conversion to DC power output, and conversion equipment without intermediate conversion to AC, which can solve the problem of low power level and high power consumption. Low reliability and slow response of the power charging device, to achieve high power factor, high voltage gain, and low device voltage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

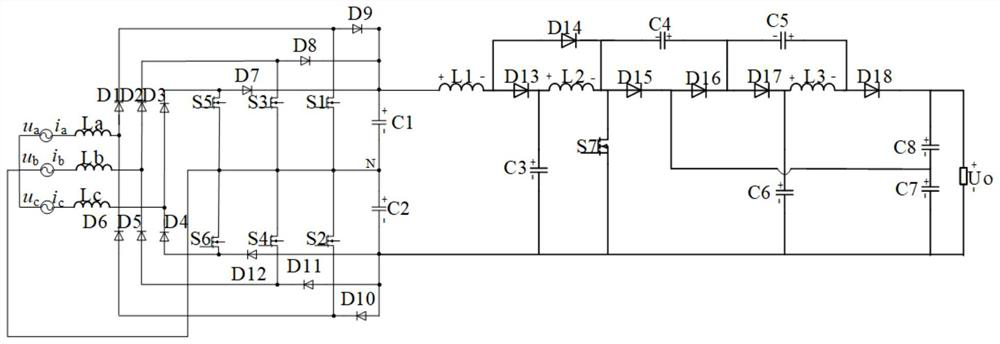

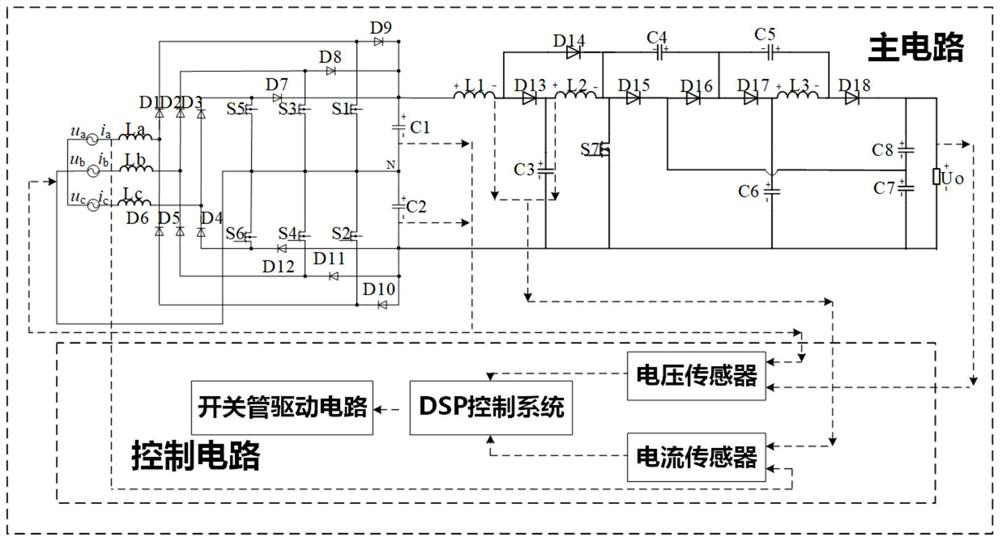

[0056] Specific implementation mode one: the following combination figure 1 This embodiment is described. The topology of a high-power charging device based on a three-level rectifier described in this embodiment includes a pre-stage three-level rectifier and a post-stage DC-DC converter;

[0057] The pre-stage three-level rectifier includes inductor La, inductor Lb, inductor Lc, diode D1, diode D2, diode D3, diode D4, diode D5, diode D6, diode D7, diode D8, diode D9, diode D10, diode D11, diode D12, switching tube S1, switching tube S2, switching tube S3, switching tube S4, switching tube S5, switching tube S6, capacitor C1 and capacitor C2;

[0058] The post-stage DC-DC converter includes inductor L1, inductor L2, inductor L3, switch S7, diode D13, diode D14, diode D15, diode D16, diode D17, diode D18, capacitor C3, capacitor C4, capacitor C5, capacitor C6 , capacitor C7, capacitor C8 and switch tube S7;

[0059] One end of the inductor La is connected to the grid-side pow...

specific Embodiment

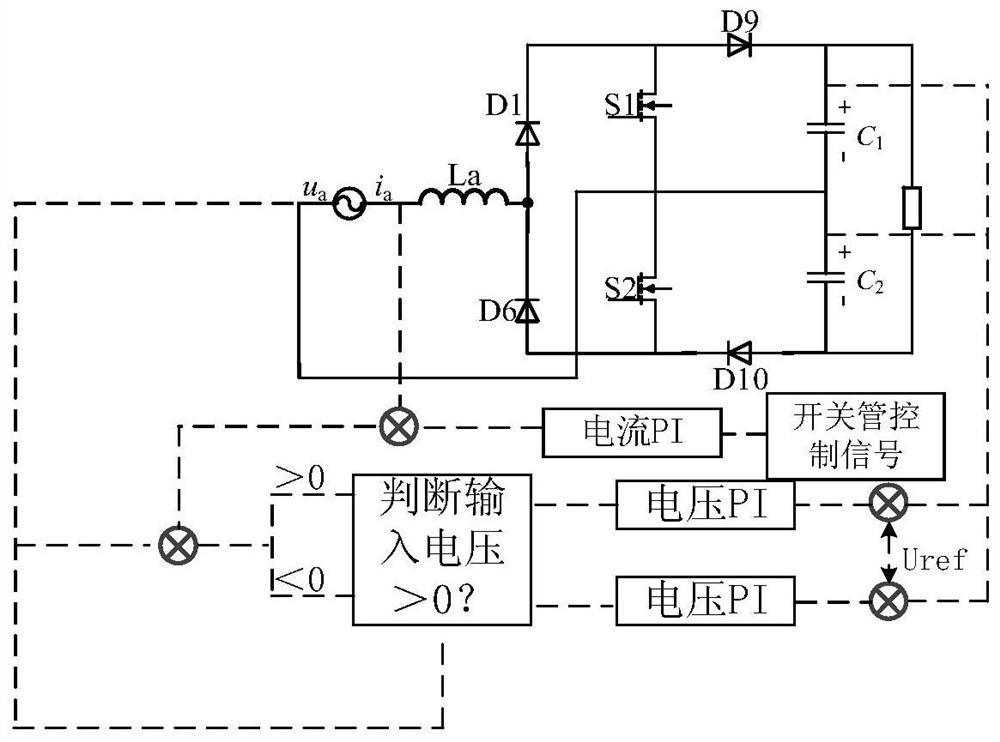

[0098] The control block diagram of the pre-stage AC-DC part is as follows image 3 As shown, the following combination image 3 Explain the specific control process:

[0099] A, collect the voltage of the capacitors C1 and C2 on the output side of the rectifier, and the three-phase voltage and current on the input side;

[0100] B. Comparing the sampled two capacitor voltages with a given reference voltage to obtain two voltage error signals of capacitor C1 and capacitor C2 respectively;

[0101] C, judge the positive or negative of the input voltage;

[0102] D. If the input voltage is positive, the voltage error signal of capacitor C1 is selected as the control signal of the voltage loop, and after the voltage loop PI control, it is output as the input value of the inner loop of the current loop;

[0103] E, if the input voltage is negative, select the voltage error signal of the capacitor C2 as the control signal of the voltage loop, after the voltage loop PI control, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com