Cylinder Thickness Gauge

A technology for thickness gauges and cylinders, which is applied in the direction of instruments, measuring devices, and optical devices, can solve the problems of low detection resolution, precision, and automation, and is not easy to detect, so that the impact of changes in the intensity of external light is small, The effect of stable light spot and obvious amplification effect

Active Publication Date: 2022-08-02

ZHONGBEI UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] When testing the cylinder in the prior art, it is often necessary to put the dial indicator and the dial gauge into the cylinder, which is more suitable for detecting the cylinder with a large diameter, and it is not easy to detect the cylinder with a small diameter

And the detection resolution, precision and automation are low

Among the existing detection methods, there are many contact detection methods and few non-contact detection methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] The embodiments of the present invention will be further described below with reference to the accompanying drawings, but the specific embodiments do not limit the present invention.

[0035] The specific implementation of the first motion pair and the second motion pair: with or without bearings.

[0036] The specific implementation of the probe head: in contact with the hole wall or not in contact with the hole wall.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

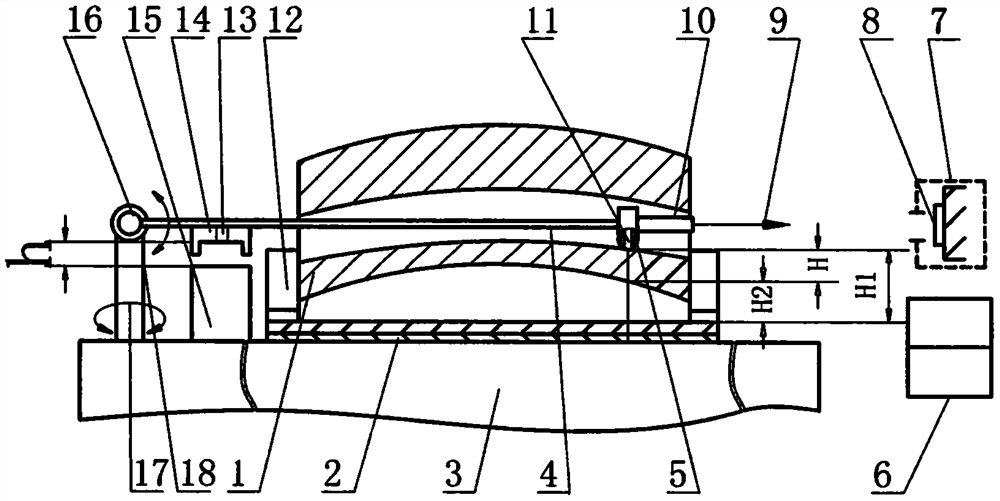

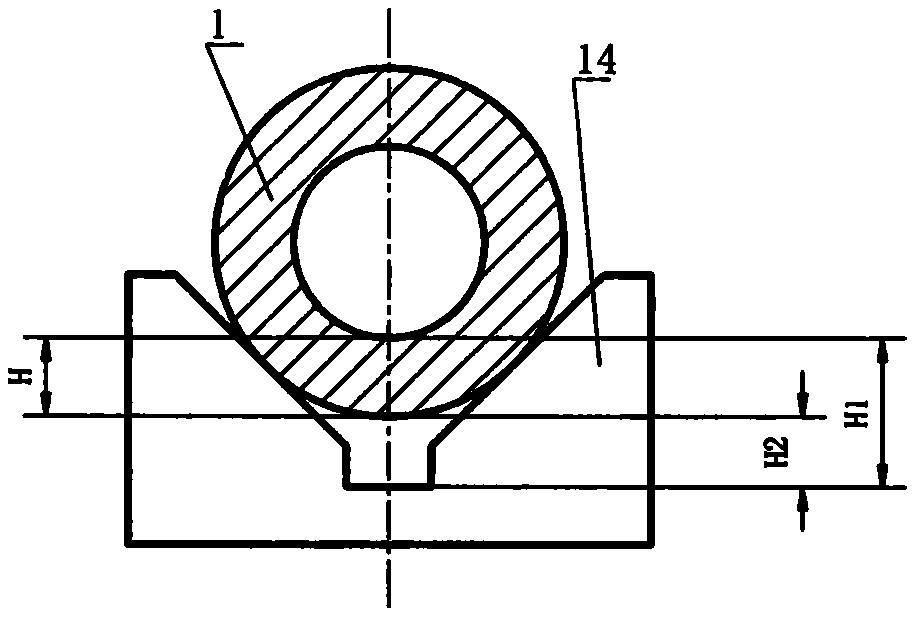

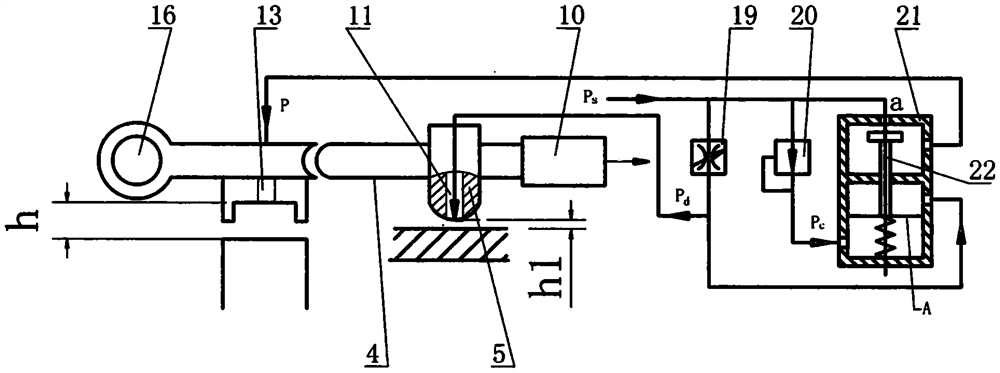

The invention belongs to the field of mechanical processing and detection, and particularly relates to a cylinder thickness gauge. The cylinder is located on the V-block and moves relative to the guide rail. The probe head on the probe rod is in contact with the hole wall or there is an air film between it and the hole wall. The light emitting device is mounted on the probe head, inside or outside the hole. When the cylinder moves, the detection rod and the detection head can rotate around the first motion pair and the second motion pair, and cause the position of the light spot to change. The first kinematic pair and the second kinematic pair each have only one rotational degree of freedom. The instrument is equipped with a throttle valve, a constant pressure valve, and an amplifying valve, which utilizes the principle of gas communication and feedback. After the detection rod is separated from the workpiece, it is located in the buffer mechanism or sags naturally. Compressed gas flows through the probe air holes and the upper support air holes. The instrument has a stable light spot, is less affected by changes in the intensity of external light, has a wide range of detection diameters, and is easy to manufacture. The instrument can realize non-contact measurement with low friction and wear.

Description

technical field [0001] The invention belongs to the field of mechanical processing and detection, and particularly relates to a cylinder thickness gauge. Background technique [0002] When detecting a cylinder in the prior art, it is often necessary to put a dial indicator and a dial indicator into the cylinder, which is more suitable for detecting a cylinder with a large diameter, but it is not easy to detect a cylinder with a small diameter. And the detection resolution, precision and automation are low. In the existing detection, there are many contact detection methods and few non-contact detection methods. During the inspection process, preventing the rotation of the measuring tool in the hole is beneficial to the orientation of the machining error, which is meaningful for quality control. SUMMARY OF THE INVENTION [0003] The purpose of the present invention is to design a cylinder detection instrument, and to provide a mechanism to prevent the rotation of the meas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/06

CPCG01B11/06

Inventor 祝锡晶

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com