A bog processing system for lng transport ship

A technology for processing systems and transport ships, which is applied in pipeline systems, transportation and packaging, gas treatment/storage purposes, etc., can solve the problems of complete decomposition of unfavorable hydrates, low decomposition efficiency, and difficulty in realization, so as to save power consumption, Easy to implement, good application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

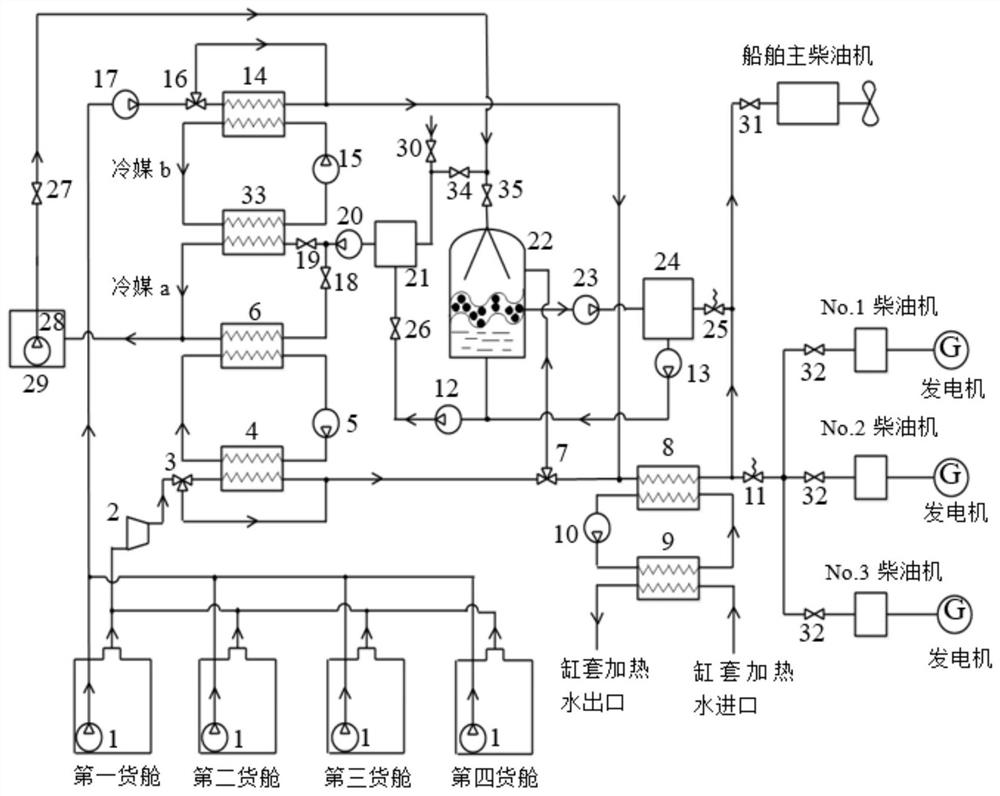

[0030] Such as figure 1 A BOG treatment system of an LNG carrier shown includes: LNG supply system, BOG fuel system, hydrate synthesis and vaporization system, and jacket water heating system.

[0031] Among them, the LNG supply system includes: transfer pump 1 , LNG heat exchanger 14 , refrigerant b circulation pump 15 , LNG three-way valve 16 , booster pump 17 , host air intake valve 31 , and refrigerant b heat exchanger 33 .

[0032] The BOG fuel system includes: compressor 2, BOG three-way valve 3, BOG heat exchanger 4, refrigerant a circulation pump 5, refrigerant a heat exchanger 6, hydrate preparation three-way valve 7, BOG pressure reducing valve 11, power generation Air intake valve 32.

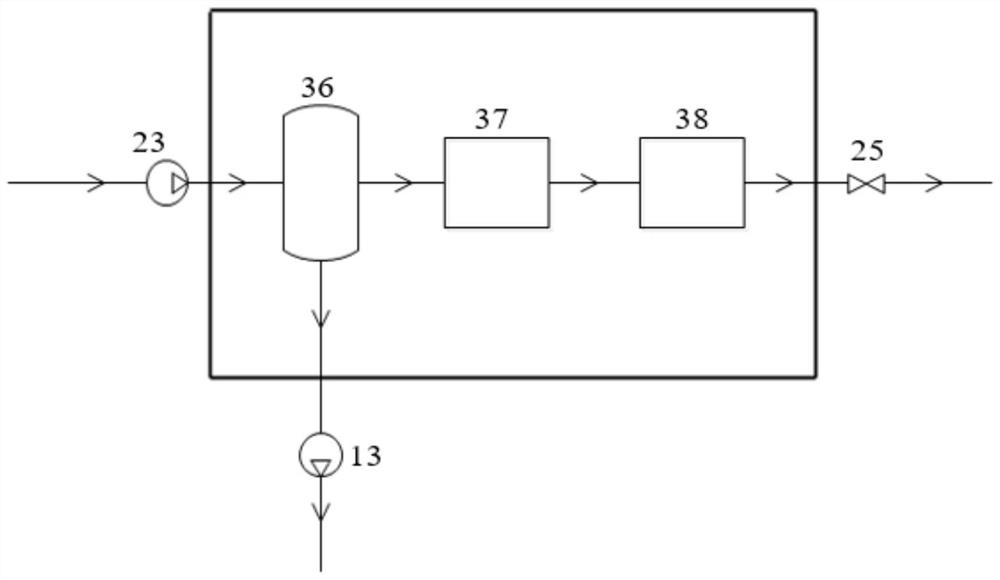

[0033] Hydrate synthesis and vaporization system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com