Integrated self-condensation drainage device

A self-condensing, integrated technology, applied in steam traps, mechanical equipment, etc., can solve problems such as water hammer and achieve the effect of reducing water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

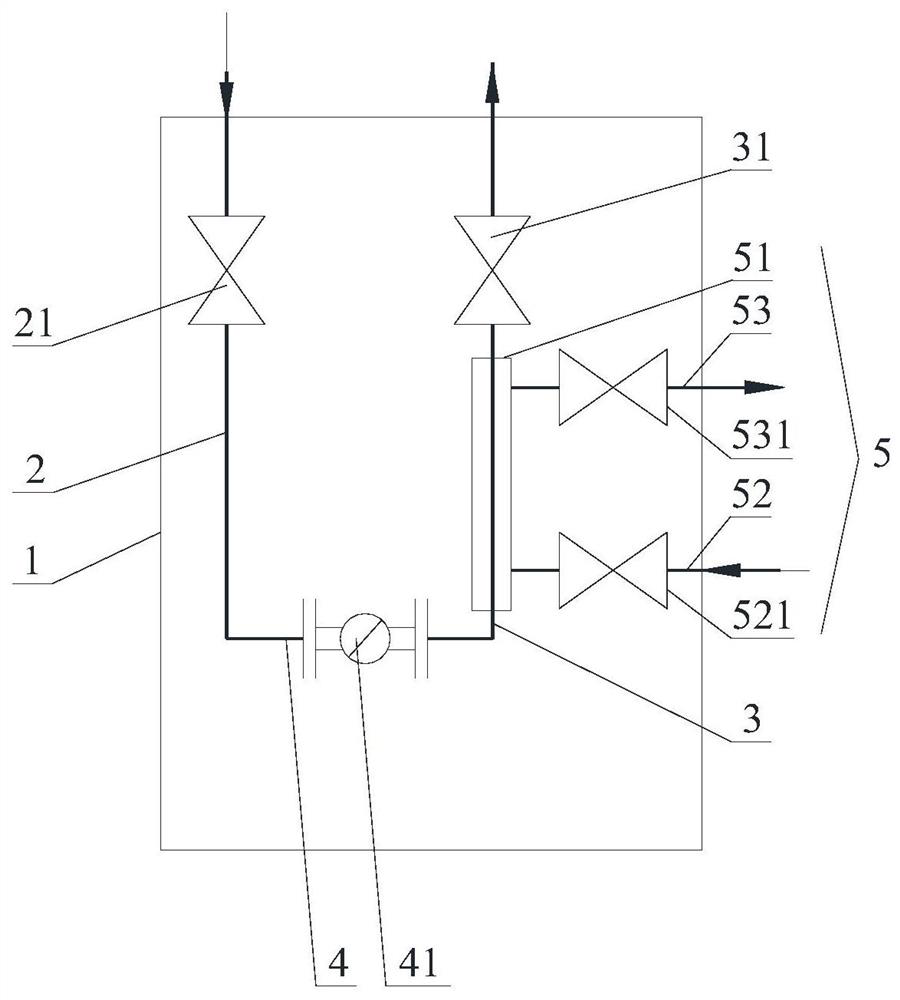

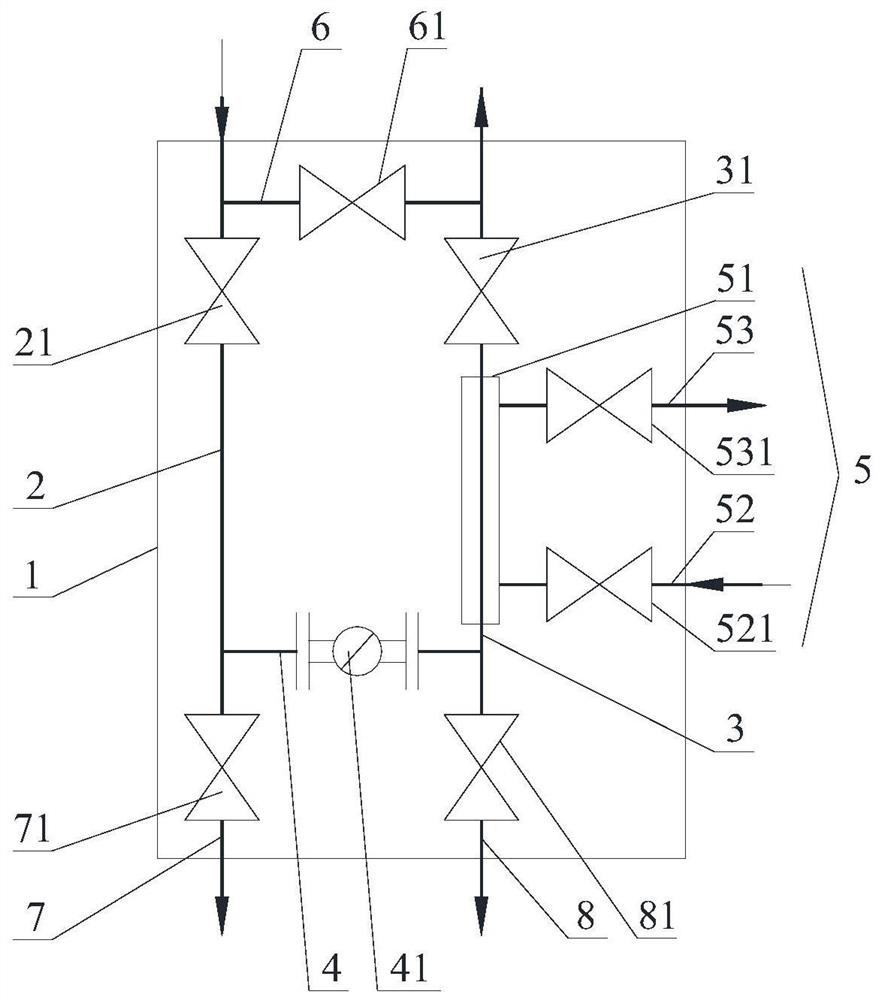

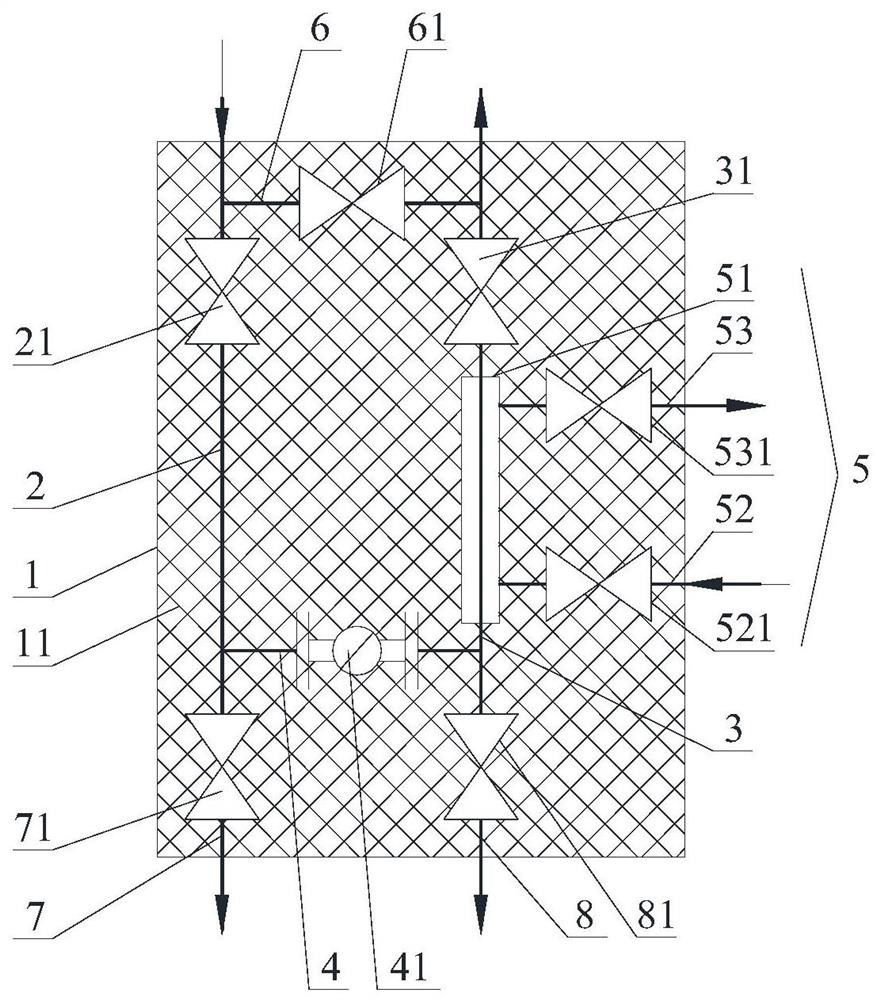

[0045] Such as Figure 1 ~ Figure 3 As shown, the present invention provides an integrated self-condensing drainage device, wherein the integrated self-condensing drainage device includes a housing 1, a steam pipeline 2, a condensate pipeline 3 and a drainage pipeline 4, a steam pipeline 2, a condensate pipeline 3 and The drain pipelines 4 are all arranged inside the shell 1, the first end of the steam line 2 runs through the shell 1 and communicates with the outside of the shell 1, the second end of the steam line 2 communicates with the first end of the drain line 4, and the second end of the steam line 4 communicates with the outside of the shell 1. The two ends communicate with the first end of the condensate pipeline 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com