Novel nozzle and fin combined type vortex reduction system

A composite, nozzle technology, used in non-variable-capacity pumps, cooling of turbines/propulsion devices, cooling of engines, etc., can solve the problems of viscous dissipation of airflow, unfavorable airflow, small flow area, etc., to reduce flow Obstruction, avoids widening and narrowing, and has the effect of large circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

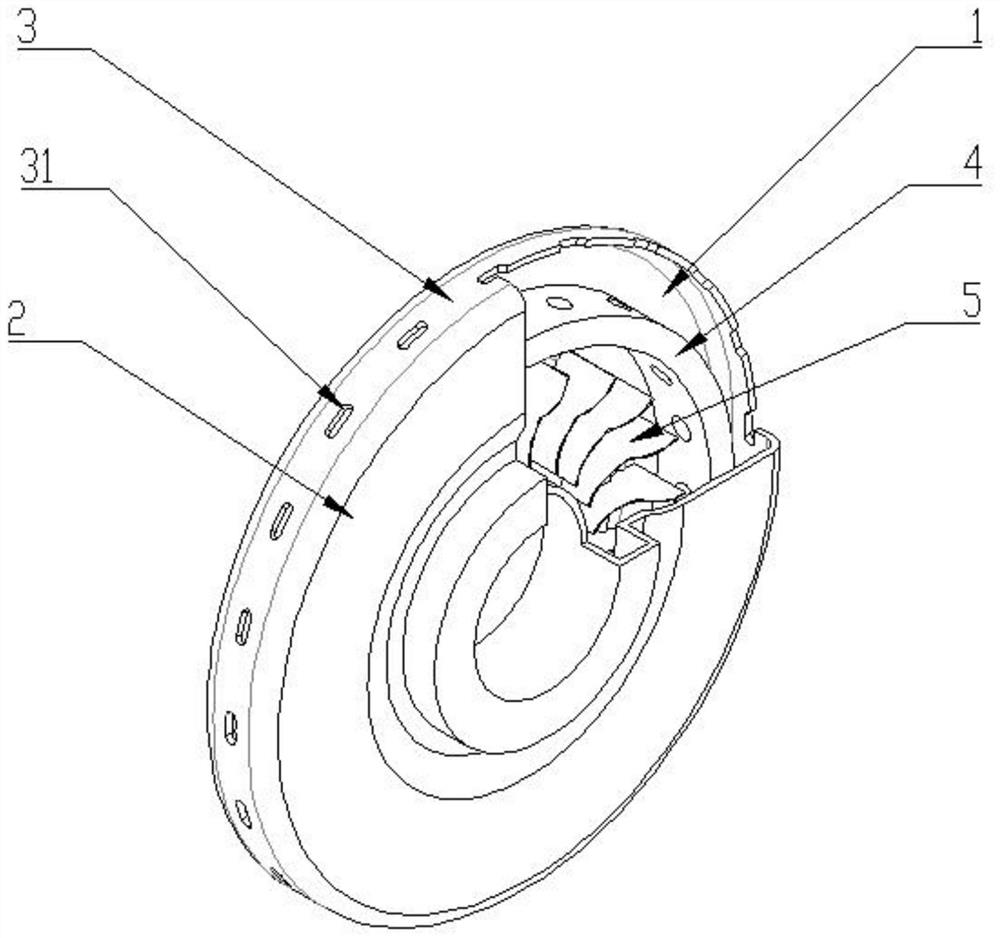

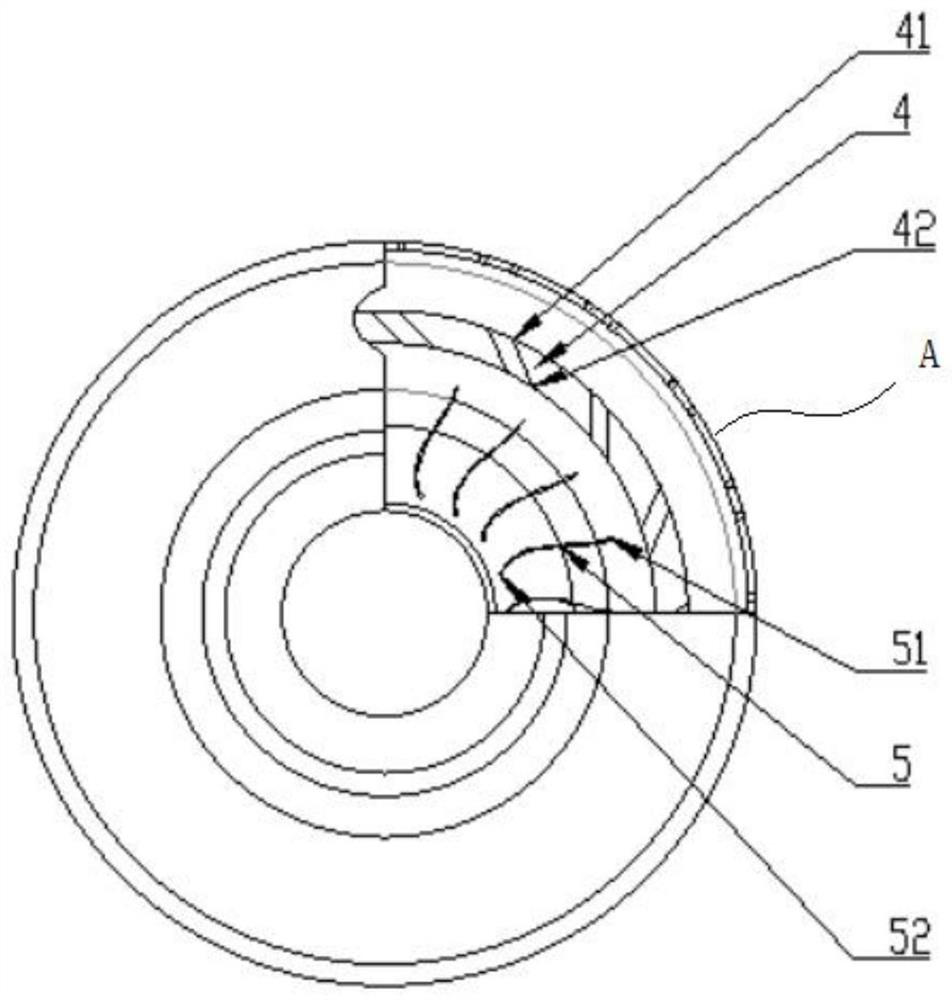

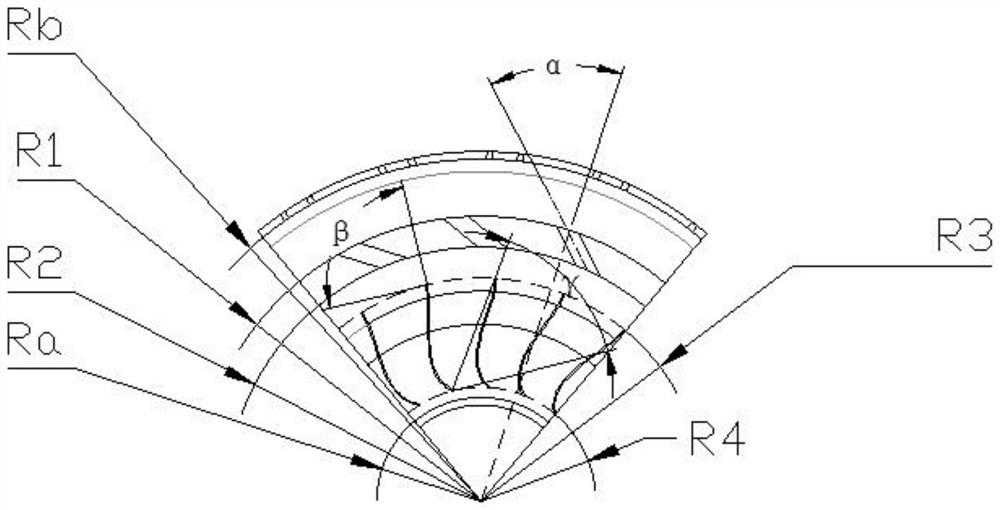

[0032] figure 1 It is a schematic perspective view of a novel nozzle-fin composite vortex reduction system according to an embodiment of the present application. figure 2 yes figure 1 Schematic front view of the nozzle-fin composite vortex reduction system shown. image 3 yes figure 1 A schematic top view of the nozzle-fin composite vortex reduction system shown.

[0033] Such as figure 1 shown, see also Figure 2-Figure 3 , this embodiment provides a novel nozzle-fin composite vortex reduction system, which is arranged at the radial flow section of the compressor of the secondary air system of the aeroengine. The compressor includes: a front-stage compressor disk 1 and a rear-stage compressor disk 2 arranged correspondingly on both sides, a drum 3 extending vertically along the outer edges of the compressor disks on both sides, and the compressor disks on both sides The disc and the drum 3 form an inner disc cavity. The drum 3 is provided with several drum holes 31 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com