Garment production cloth cleaning and cutting device

A technology of cutting device and cleaning device, which is applied in the field of garment processing and production, can solve problems such as difficulty in meeting cutting standards, waste of resources and time, and low operating efficiency, and achieve the effects of easy pulling operation, reduced usage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

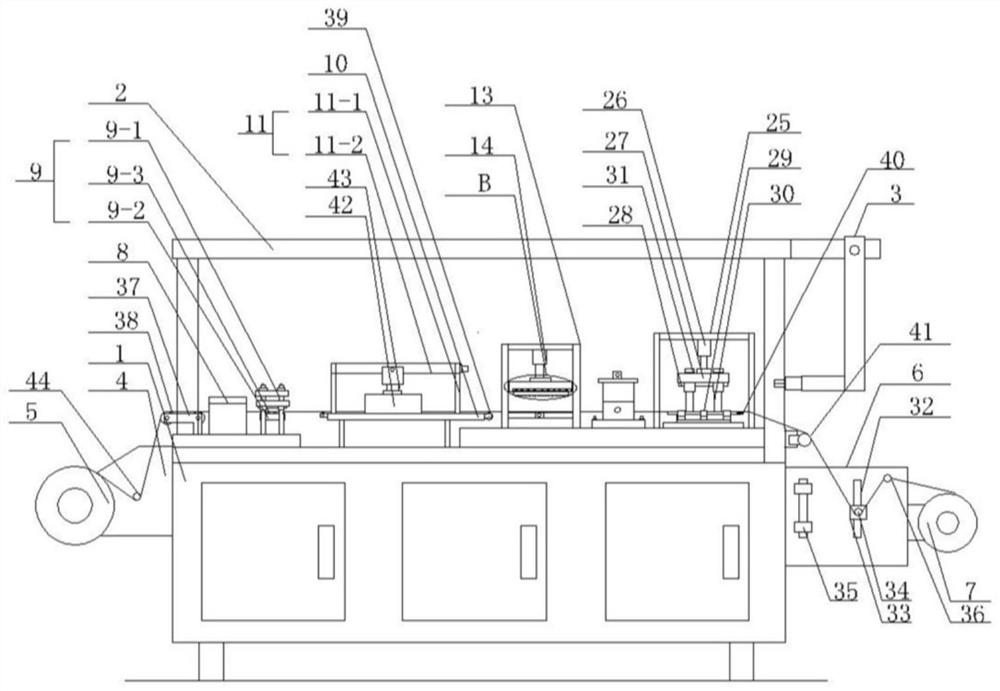

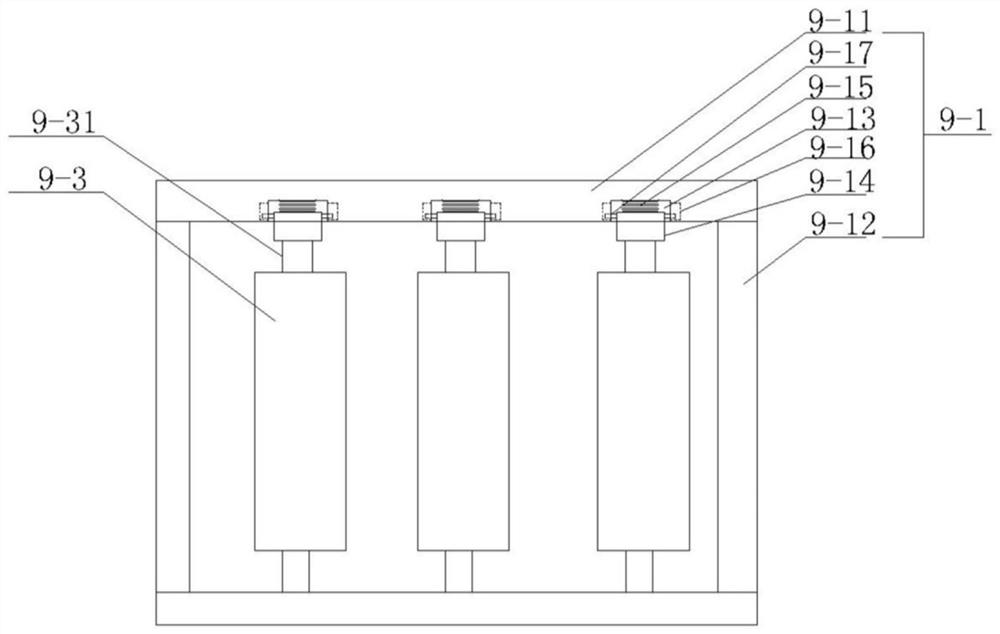

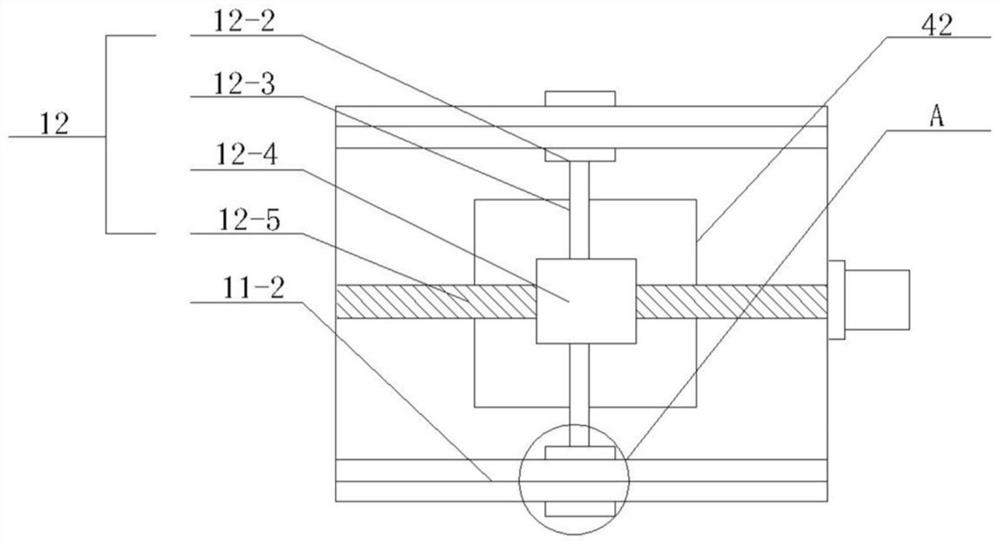

[0028] Such as Figure 1 to Figure 6 As shown, a cloth cleaning and cutting device for garment production according to the present invention includes a support platform 1, and the left and right sides of the support platform 1 are respectively provided with a conveying device and a waste collection device, and the top of the support platform 1 is sequentially arranged from left to right There are cloth cleaning devices, ironing devices, embossing devices, traction devices and cutting devices; the top of the support platform 1 is provided with a sealing bracket 2, and the right end of the sealing bracket 2 is hingedly provided with a mechanical gripper 3, which is used for cutting The cloth that comes down is moved to the next station for operation and processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com