Glue-free reconstituted veneer and preparing method thereof

A technology for veneer and wood, applied in the field of glue-free reconstituted veneer and its preparation, can solve problems such as toxic and harmful volatiles, and achieve the effects of high market value, good dimensional stability, and control of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

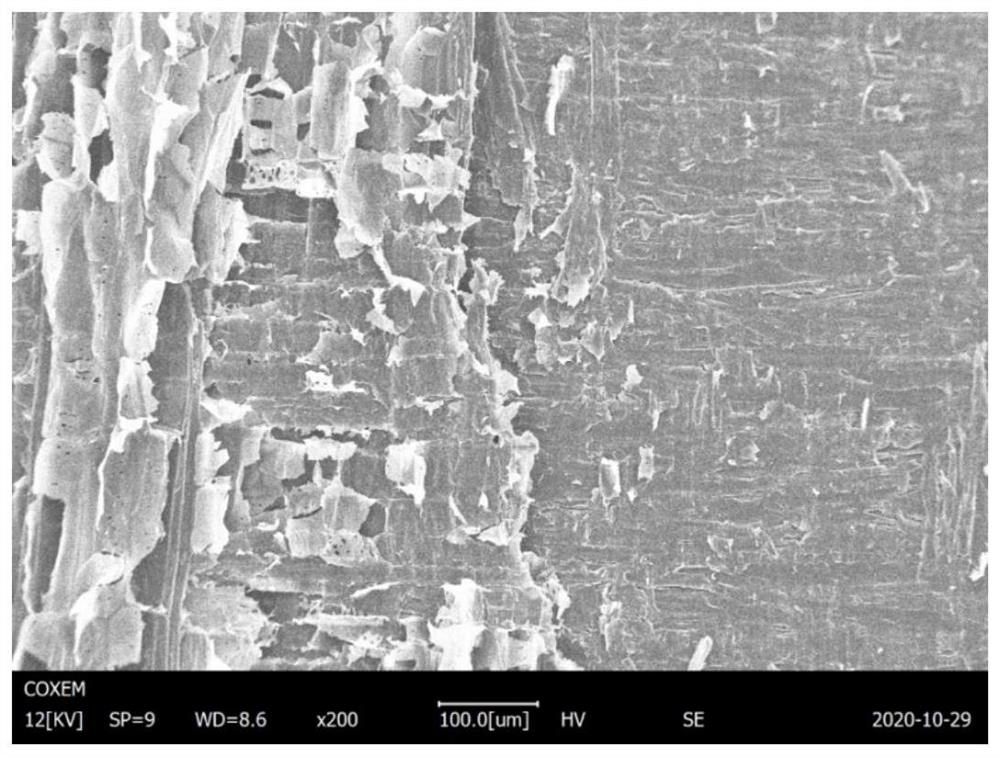

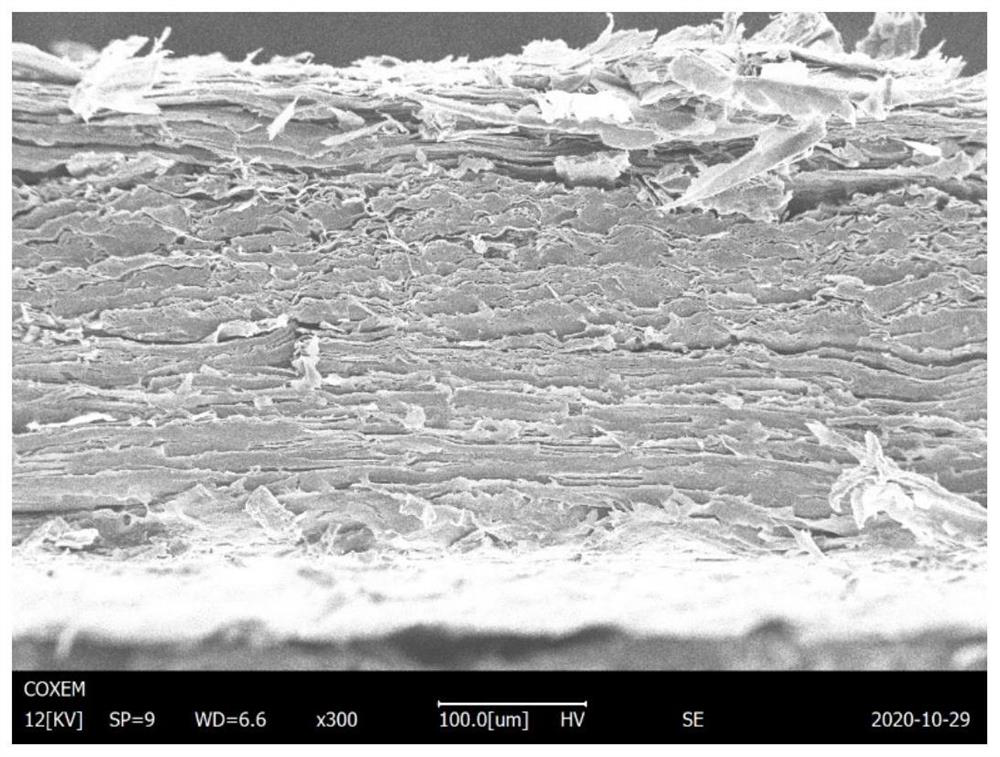

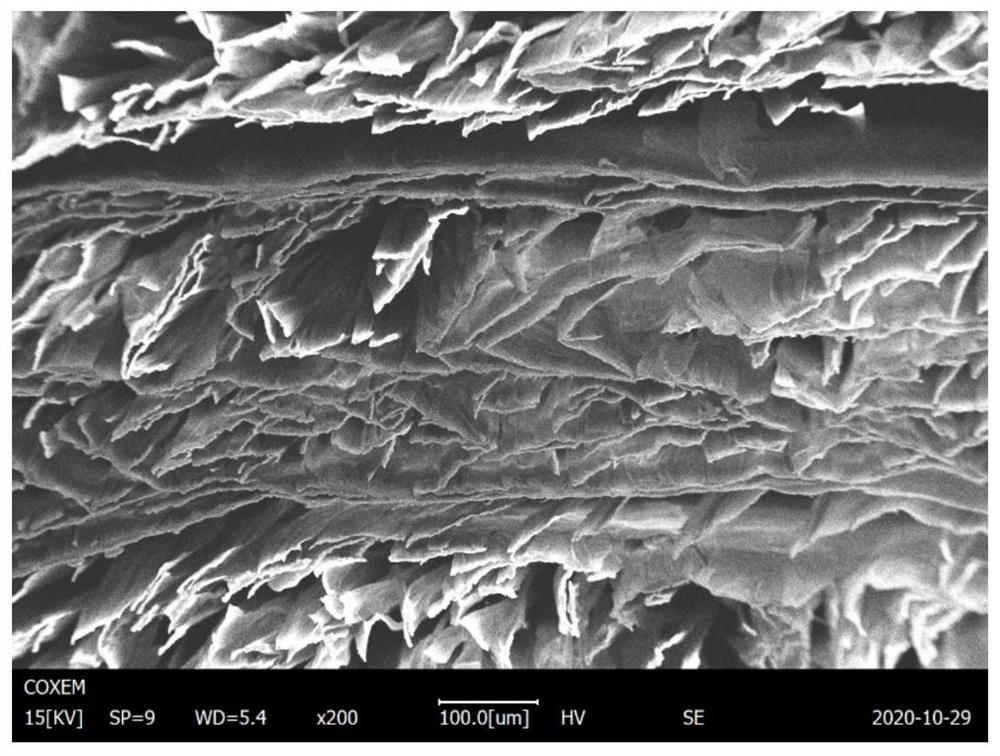

Image

Examples

Embodiment 1

[0024] This example provides a method for preparing recombined veneer without glue, using a delignification solution to perform delignification treatment on fast-growing wood veneers to obtain delignified wood samples, and removing the delignified wood samples from the obtained delignified wood samples by cold pressing. 80% moisture, and then hot-pressed and dried to obtain restructured veneer without glue.

Embodiment 2

[0026] This embodiment provides a method for preparing recombined veneer without glue, and the specific steps are as follows:

[0027] Step 1. Using a delignification solution to delignify the fast-growing wood veneer:

[0028] Put the fast-growing wood veneer with a thickness of 0.8-1.5mm in 1-2wt% sodium chlorite solution for vacuum treatment, so that the delignification solution can fully penetrate into the fast-growing wood veneer, and then place the fast-growing wood veneer in Keeping in 1-2 wt% sodium chlorite solution with a pH value of 4.6 controlled by glacial acetic acid for 4-8 hours at 80-100° C., natural cooling and washing with distilled water for 3-6 times to obtain delignified wood samples;

[0029] The fast-growing wood is any one or a combination of poplar, eucalyptus, Chinese fir, pine, willow, balsa and paulownia.

[0030] Step 2, remove the moisture in the obtained delignified wood sample by cold pressing:

[0031] Arrange and stack the delignified wood ...

Embodiment 3

[0035] This embodiment provides a kind of recombined veneer glued without glue, and the specific steps of its preparation method are as follows:

[0036] Step 1. Using a delignification solution to delignify the fast-growing wood veneer:

[0037] Put a poplar veneer with a thickness of 0.8mm in a 1wt% sodium chlorite solution for vacuum treatment, so that the delignification solution can fully penetrate into the fast-growing veneer, and then place the fast-growing veneer in a vacuum controlled by glacial acetic acid. Keep the 2wt% sodium chlorite solution with a pH value of 4.6 at 80° C. for 4 hours, and wash with distilled water 3 times after natural cooling to obtain a delignified wood sample;

[0038] Step 2, remove the moisture in the obtained delignified wood sample by cold pressing:

[0039] The delignified wood samples obtained in step 1 were stacked in three layers and placed between stainless steel filter screens with a pore size of 800 mesh. A layer of cardboard was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com