Surface rust-proof treatment equipment for air pipe production

A technology of anti-rust treatment and equipment, which is applied in the direction of surface coating liquid devices, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of reducing the production efficiency of air ducts, rusting, etc., and achieve improved painting efficiency. Efficiency, convenient effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

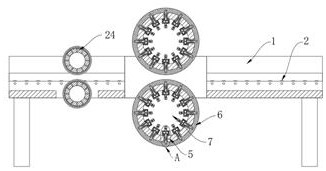

[0026] refer to Figure 1-5 , a surface anti-rust treatment equipment for air duct production, including a transmission assembly, a painting assembly and a dust collection assembly, the transmission assembly includes a flat-shaped transmission frame 1, and the inner front wall and the inner rear wall of the flat-shaped transmission frame 1 are provided with transmission groove, and the inner bottom walls of the two transmission grooves are all rotatably connected with several transmission wheels 2, and the front and back sides of the square transmission frame 1 are fixedly connected with drive motor boxes 18, and the insides of the two drive motor boxes 18 are all provided with There are driving motors, the output ends of the two driving motors are fixedly connected with the two transmission wheels 2 on the far right, and several transmission wheels 2 are connected by belt transmission.

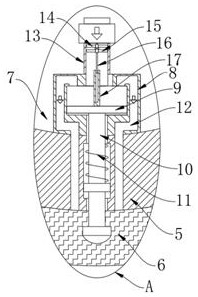

[0027] The painting assembly includes four support plates 3 fixedly connected to the uppe...

Embodiment 2

[0033] refer to Figure 6 The dust suction assembly includes two dust suction rollers 24 that are connected to the inner wall of the X-shaped transmission frame 1 through the rotating shaft 23, and the inside of the two dust suction rollers 24 is provided with a dust suction cavity, and the outer surfaces of the two dust suction rollers 24 are uniform. There are several dust suction holes, and the outer surfaces of the two dust suction rollers 24 are fixedly connected with cleaning brushes, the two dust suction rollers 24 are meshed through transmission gears, and the bottom rotating shaft 23 on the back is connected to the transmission wheel 2 through a belt .

[0034] One end of the two rotating shafts 23 on the front is all rotatably connected with a second sealed bearing 25, and the outer surfaces of the two second sealed bearings 25 are fixedly connected with a ventilation pipe 26, and the outer surface of the second sealed bearing 25 on the upper part is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com