Super-hydrophilic low-molecular-weight intercepted graphene composite ultrafiltration membrane and manufacturing method thereof

A graphene composite and manufacturing method technology, applied in ultrafiltration, chemical instruments and methods, membranes and other directions, can solve the problems of low retention rate of bovine serum albumin aqueous solution, easily contaminated MBR membrane, short service life, etc. Water and pollution resistance, good mechanical properties and swelling resistance, the effect of increasing flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

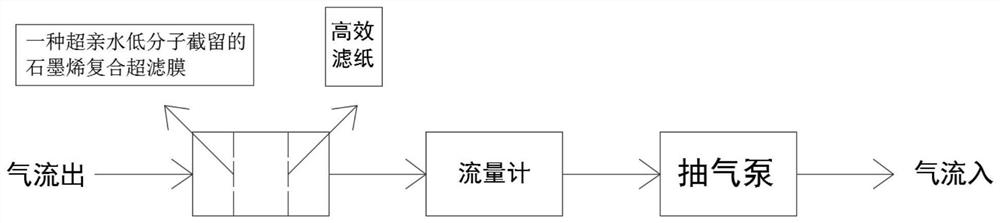

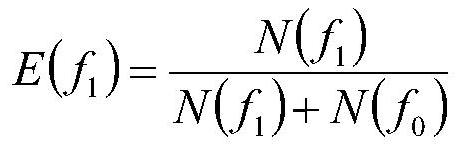

Image

Examples

Embodiment 1

[0037] S1: Pour acetone into N-methylpyrrolidone (NMP), heat to 70°C, add polyvinylpyrrolidone (PVPk30), polyvinylpyrrolidone (PVPk90), polyvinylidene fluoride (PVDF), the polyvinylpyrrolidone ( The mass ratio of PVPK30) to polyvinylpyrrolidone (PVPk90) and polyvinylidene fluoride (PVDF) is 1:1:1.76. After stirring for a period of time, the polysulfone ultrafiltration membrane solution prepared by graphene oxide blending is added, and the polysulfone ultrafiltration membrane liquid is implanted into poly The aminated titanium dioxide nanoparticles on the surface of the sulfone ultrafiltration channel are mixed to make a casting solution for 2 hours after stirring;

[0038] S2: the casting solution obtained in S1 is left to stand for a period of time, and the homogeneous casting solution is obtained after the bubbles are released;

[0039] S3: scrape the homogeneous film casting liquid obtained in S2 into a flat film on a glass plate, put it into deionized water, maintain the w...

Embodiment 2

[0043] S1: Pour acetone into N-methylpyrrolidone (NMP), heat to 70°C, add polyvinylpyrrolidone (PVPk30), polyvinylpyrrolidone (PVPk90), polyvinylidene fluoride (PVDF), the polyvinylpyrrolidone ( The mass ratio of PVPK30) to polyvinylpyrrolidone (PVPk90) and polyvinylidene fluoride (PVDF) is 1:1:1.76. After stirring for a period of time, the polysulfone ultrafiltration membrane solution prepared by graphene oxide blending is added, and the polysulfone ultrafiltration membrane liquid is implanted into poly The aminated titanium dioxide nanoparticles on the surface of the sulfone ultrafiltration channel are mixed to make a casting solution for 2 hours after stirring;

[0044] S2: the casting solution obtained in S1 is left to stand for a period of time, and the homogeneous casting solution is obtained after the bubbles are released;

[0045] S3: scrape the homogeneous film casting liquid obtained in S2 into a flat film on a glass plate, put it into deionized water, maintain the w...

Embodiment 3

[0049] S1: Pour acetone into N-methylpyrrolidone (NMP), heat to 70°C, add polyvinylpyrrolidone (PVk30), polyvinylpyrrolidone (PVPk90), polyvinylidene fluoride (PVDF), the polyvinylpyrrolidone ( The mass ratio of PVPK30) to polyvinylpyrrolidone (PVPk90) and polyvinylidene fluoride (PVDF) is 1:1:1.76. After stirring for a period of time, the polysulfone ultrafiltration membrane solution prepared by graphene oxide blending is added, and the polysulfone ultrafiltration membrane liquid is implanted into poly The aminated titanium dioxide nanoparticles on the surface of the sulfone ultrafiltration channel are mixed to make a casting solution for 2 hours after stirring;

[0050] S2: the casting solution obtained in S1 is left to stand for a period of time, and the homogeneous casting solution is obtained after the bubbles are released;

[0051] S3: scrape the homogeneous film casting liquid obtained in S2 into a flat film on a glass plate, put it into deionized water, maintain the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com