End-capping paper of heat-not-burn cigarette, sealing method and smoking set

A heat-not-burn, cigarette stick technology, applied to tobacco and other fields, can solve the problems of heating and increasing the user's suction resistance, and achieve the effect of increasing air permeability and preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

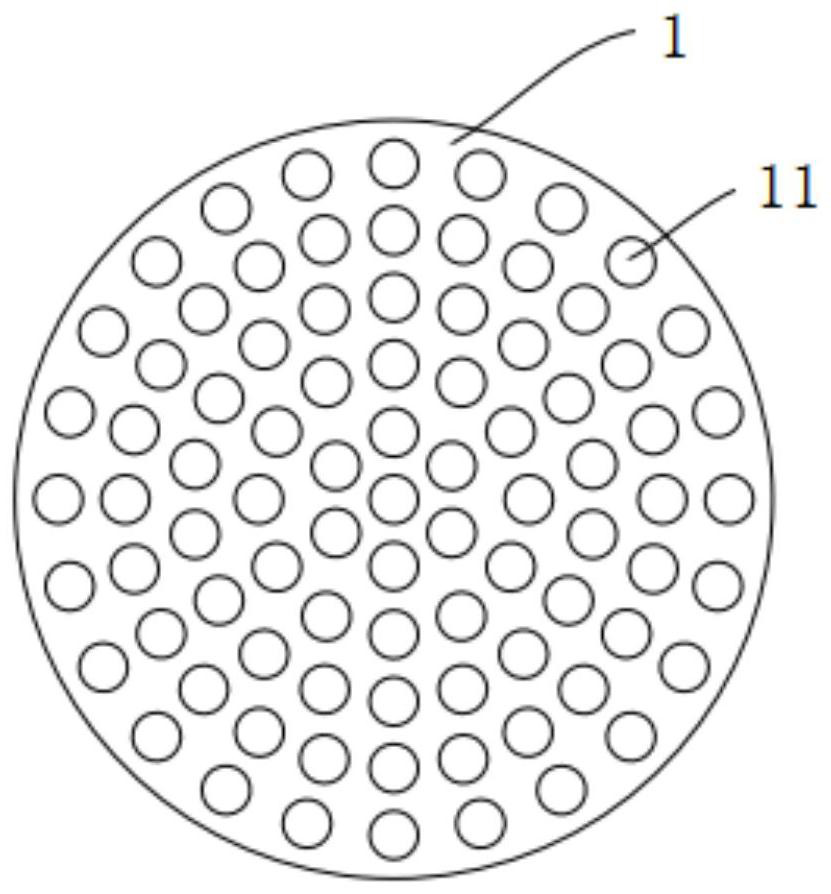

[0086] Please refer to figure 1 , the present invention provides a heat-not-burn cigarette end-sealing paper, which includes a sealing round paper 1 that is easily pierced by a heating needle; the sealing round paper 1 is provided with a number of micropores 11, and the micropores 11 are neatly formed. Arranged or randomly arranged; the micropores 11 are in a circular shape, the diameter of the micropores 11 is smaller than the diameter of the smoke particles of the heat-not-burn cigarette, and the diameter of the micropores 11 is 20nm-50nm; the density of the micropores 11 is 200-300 pieces / cm2, the diameter of the sealing round paper sheet 1 is 0.8cm-1.2cm, and the air permeability of the sealing round paper sheet 1 is 1000-5000CU.

[0087] Specifically, the set of several micropores 11 increases the air permeability, so that when the heating is aimed at the smoking particles, the external air enters into the cigarette, which is helpful for the generation of the smoke of the...

Embodiment 2

[0091] On the basis of embodiment 1,

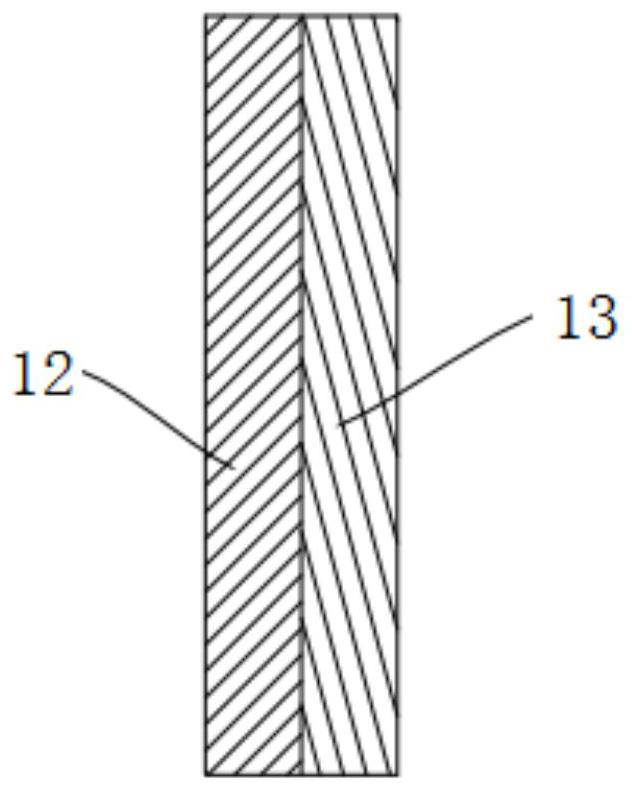

[0092] Further, please refer to figure 2 The sealing round paper sheet 1 includes a first layer; the first layer is a tipping paper layer 13; the thickness of the tipping paper layer 13 is 0.3mm-0.5mm. The tensile strength of the tipping paper layer 13 is 1.3-1.8 / g.cm-3. The sealing round paper sheet 1 also includes a second layer; the second layer is positioned on the inner side of the tipping paper layer 13, the second layer is a high air permeability molding paper layer 12, and the thickness of the high air permeability molding paper layer 12 is 0.2mm -0.6mm. The high air permeability forming paper layer 12 is made of one or a mixture of hardwood sulfite pulp, hardwood kraft pulp, softwood sulfite pulp and softwood kraft pulp. The sealing round paper sheet has a certain tensile strength, so it can prevent the falling of smoke particles caused by the damage of the sealing round paper sheet during transportation or unused state.

[...

Embodiment 3

[0102] On the basis of embodiment 1 or 2, such as Figure 4-5 As shown, the smoking set 2 includes:

[0103] The shell 21, the shell 21 is provided with a partition 26, which is divided into an upper chamber 211 and a lower chamber 212 by the partition, and a through hole is arranged on the partition;

[0104] The cigarette container 22 includes: an outer container 221, and an inner container 222 slidably arranged in the outer container 221, and the heat-not-burn cigarette is inserted into the inner container 222;

[0105] The heating device 23 and the battery are all arranged in the lower chamber 212, the heating device 23 includes a heating needle 231, and the heating device is inserted into the inner container 222 through the through hole, and the heating needle 231 is inserted in the lower chamber 212 A control device 24 for controlling the heating device 23 is provided; the control device and the heating device are powered by a battery.

[0106] The push-out and clampin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com