Bun production process

A production process and bread technology, applied in the field of small bread, can solve the problems of low output and low work efficiency, and achieve the effects of high degree of automation, improved quality and reduced defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

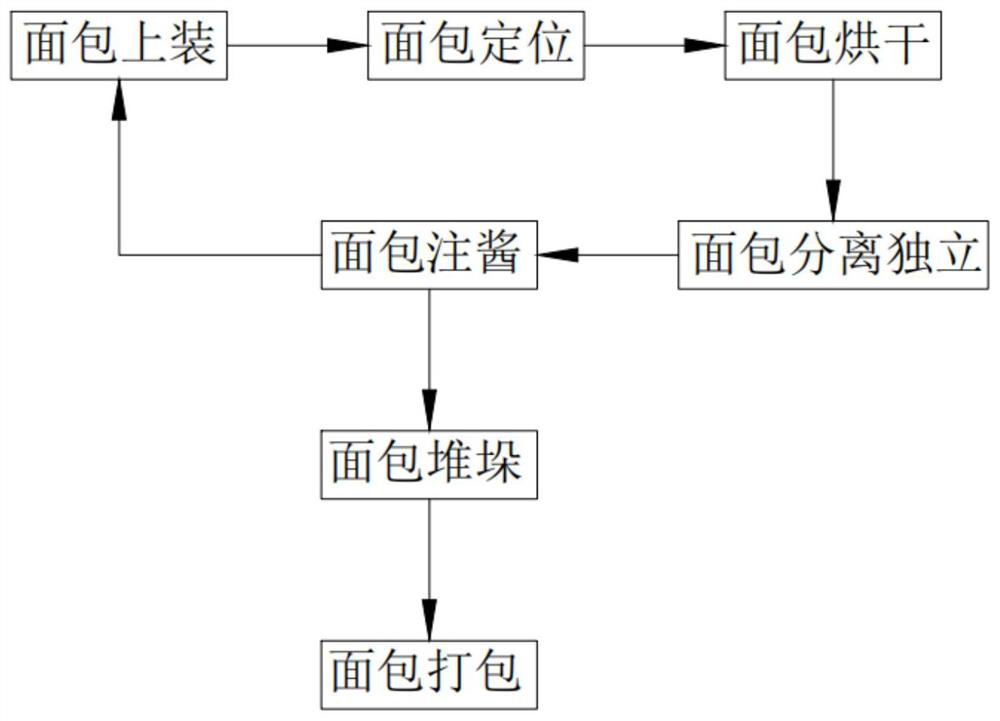

[0057] Such as figure 1 Shown, a kind of small bread production technique comprises:

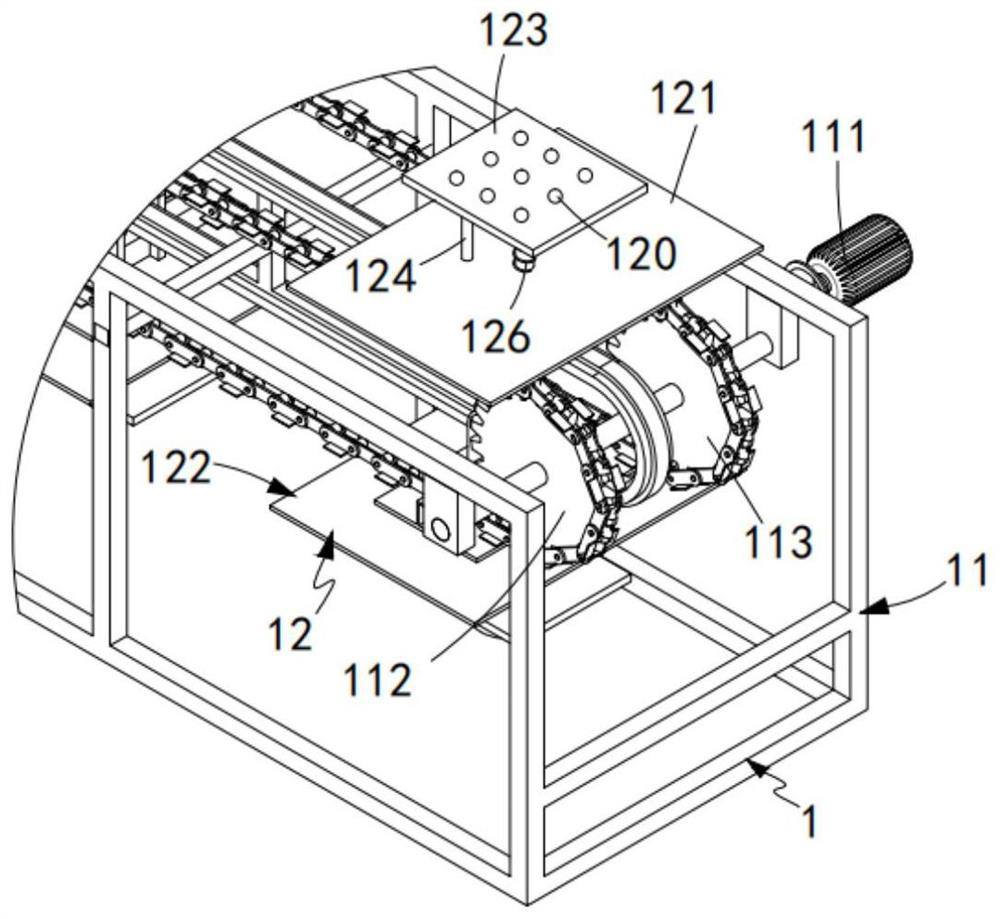

[0058] Step 1, the bread is loaded, and the bread group 10 is manually placed on the tray 123 of the carrying assembly 12, and the carrying assembly 12 is automatically transported backward under the action of the first transmission assembly 11;

[0059] Step 2, positioning the bread. During the transmission of the bread in the carrying assembly 12, the pull rod b2216 acts on the pull rod a2215, and pulls the pull rod a2215 to move synchronously with the first transmission rack 2213. During the movement, the first transmission rack 2213 drives the second A transmission gear 2212 rotates. During the rotation, the transmission part 2211 is automatically driven. During the transmission process of the concentration part 222, the control column b2222 is limited by the guide rail b2224. After closing, it will be opened automatically. After the rectangular plate 2223 is fully opened, the telescopi...

Embodiment 2

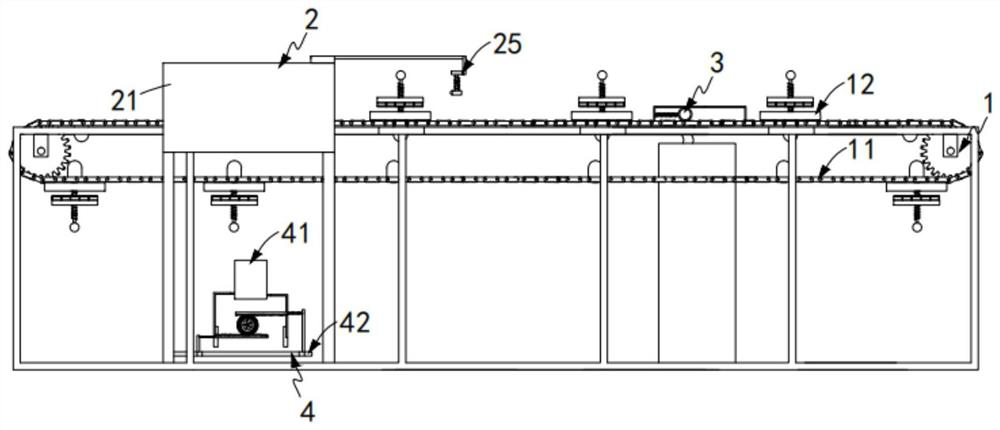

[0076] Such as figure 2 As shown, a dryer for small bread production with good drying effect, including:

[0077] A transmission mechanism 1, the transmission mechanism 1 comprising a first transmission assembly 11 and several groups of bearing assemblies 12 equidistantly arranged on the first transmission assembly 11;

[0078] Drying mechanism 2, the drying mechanism 2 includes a drying box 21 sleeved outside the transmission mechanism 1, a positioning assembly 22 arranged at the input end of the drying box 21, and a positioning assembly 22 arranged in the drying box 21 And the first sub-assembly 23 for lateral sub-assembly, two sets of clamping assemblies 24 symmetrically arranged on both sides of the sub-assembly, and the clamping assembly 24 arranged outside the drying box 21 and cooperating with the clamping assembly 24 The second sub-assembly 25 for longitudinal sub-division work;

[0079] Injection mechanism 3, which is arranged outside the drying box 21 and arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com