Method of manufacturing outer case for hot water unit

A manufacturing method and casing technology, applied in the direction of copying/marking method, device for coating liquid on the surface, application, etc., capable of solving problems such as high cost, pollution or fading, and damage to the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

[0036]First, in order to be readily understood, the outer casing C of the warm water unit used by the manufacturing method of the present embodiment is used as the structure of the warm water unit U of the outer casing C for the warm water unit.

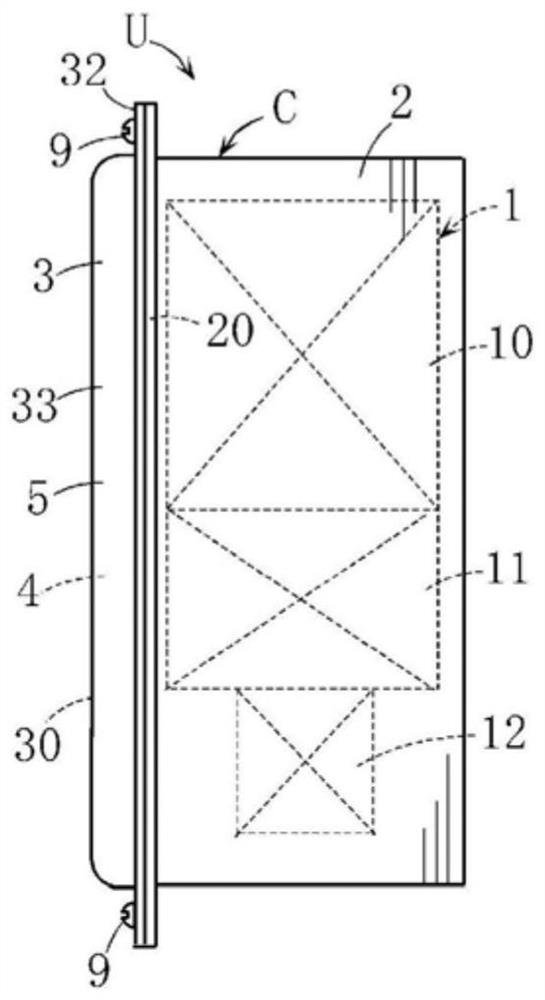

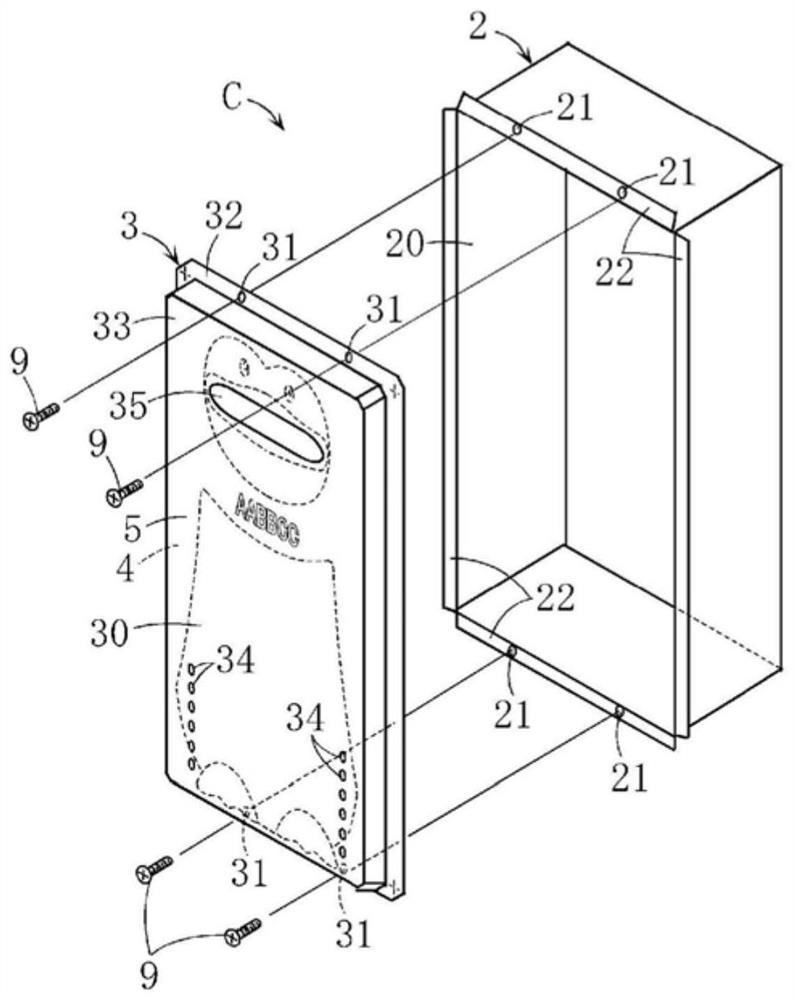

[0037]inFigures 1a to 2b In the middle, the warm water unit U corresponds to the hot water supply device, including the outer casing C, and contains warm water equipment 1 for warm water in the outer casing C. The warm water device 1 includes a heat exchanger 10 flowing through hot water for heating a combustor 11 that is heated in the heat exchanger 10, and a fan (FAN) that supplies the burning air to the burner 11. 12.

[0038]The outer casing C includes a rectangular case-shaped outer casing body 2 having an opening portion 20 on the front surface, and a cover 3 (front cover) that blocks the opening portion 20. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com