Curing composition, method for producing photospace material and liquid crystal display device

A curable composition and surface-active technology, applied in the direction of nonlinear optics, optics, photolithography process of pattern surface, etc., to achieve the effect of preventing uneven display and eliminating deformation recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0173] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited by the following examples within the range not exceeding the gist. In addition, unless otherwise specified, "part" and "%" are mass standards.

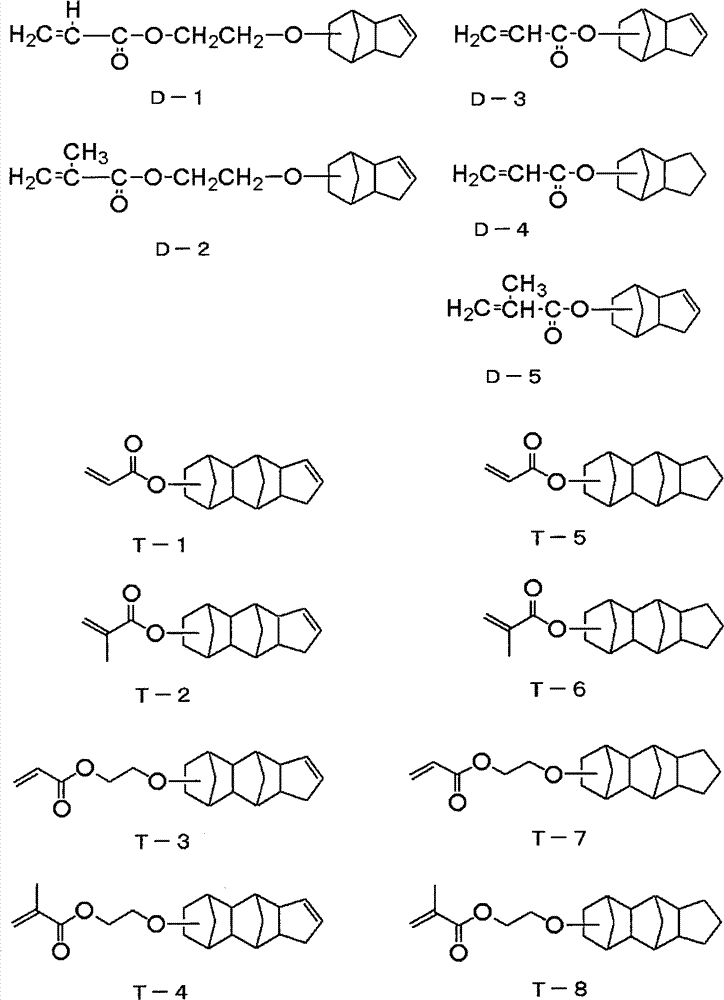

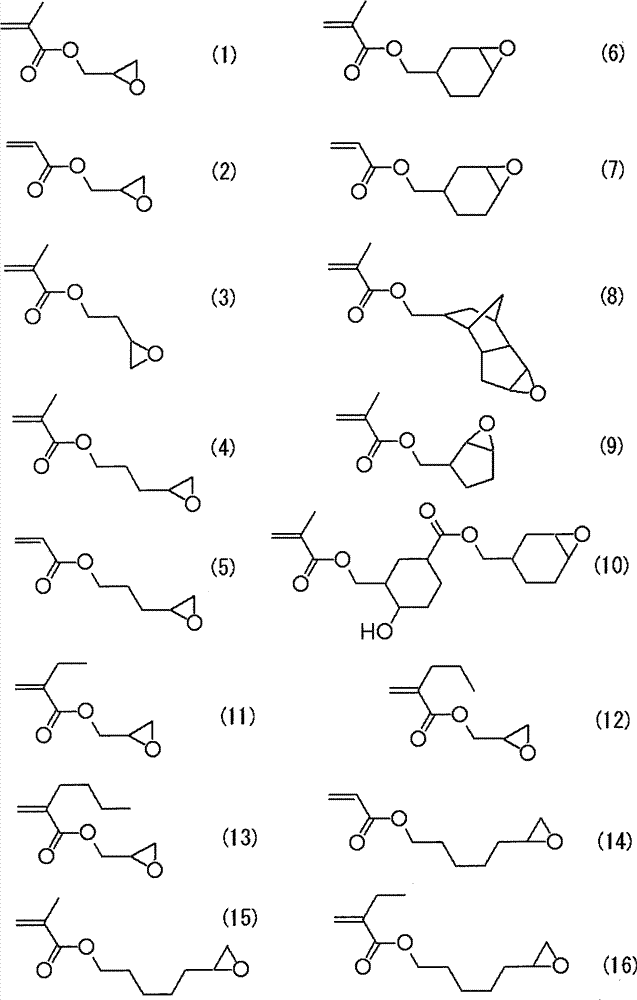

[0174] As the resin (A) in the present invention, synthesis examples of compounds represented by compound structures P-1 to P-5 are shown below.

Synthetic example 1

[0176] 203.9 parts of 1-methoxy-2-propanol (MFG, manufactured by Daicel Chemical Industry Co., Ltd.) was added to the reaction vessel in advance, and the temperature was raised to 70° C. under a nitrogen atmosphere, and 12.5 parts of styrene was instilled over 2 hours, shrinking 76.8 parts of glycerin methacrylate, 66.1 parts of dicyclopentenyl methacrylate, 46.5 parts of methacrylic acid, and 9.5 parts of an azo polymerization initiator (manufactured by Wako Pure Chemical Industries, Ltd., V-65). After dripping, it was allowed to react for 4 hours to obtain a solution (28.6% solution) of the resin represented by Compound Structure P-1.

[0177] The weight average molecular weight Mw of the resin represented by the compound structure P-1 was determined by gel permeation chromatography and found to be 31,500.

Synthetic example 2

[0179] In Synthesis Example 1, except that 2-adamantyl methacrylate was used instead of biscyclopentenyl methacrylate, the resin represented by compound structure P-2 was obtained in the same manner as in Synthesis Example 1. solution (28.0% solution).

[0180] The weight average molecular weight Mw of the resin represented by the compound structure P-2 was 28,700.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com