Power insulator surface treatment system

A surface treatment and insulator technology, which is applied in the field of power insulator surface treatment system, can solve problems such as insulator damage, incomplete grinding, and grinding failure, and achieve the effect of changing the contact area and pressure, and adjusting the grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

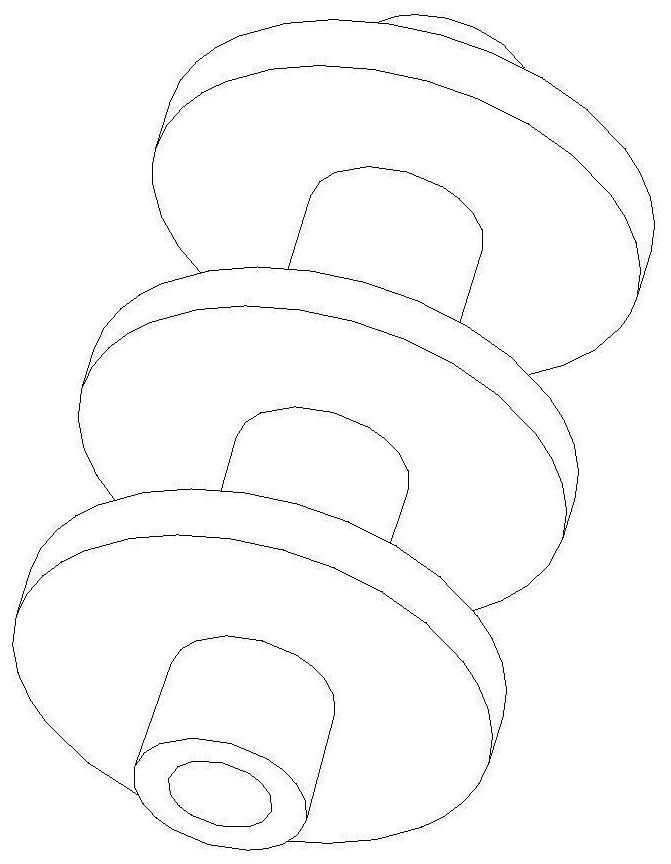

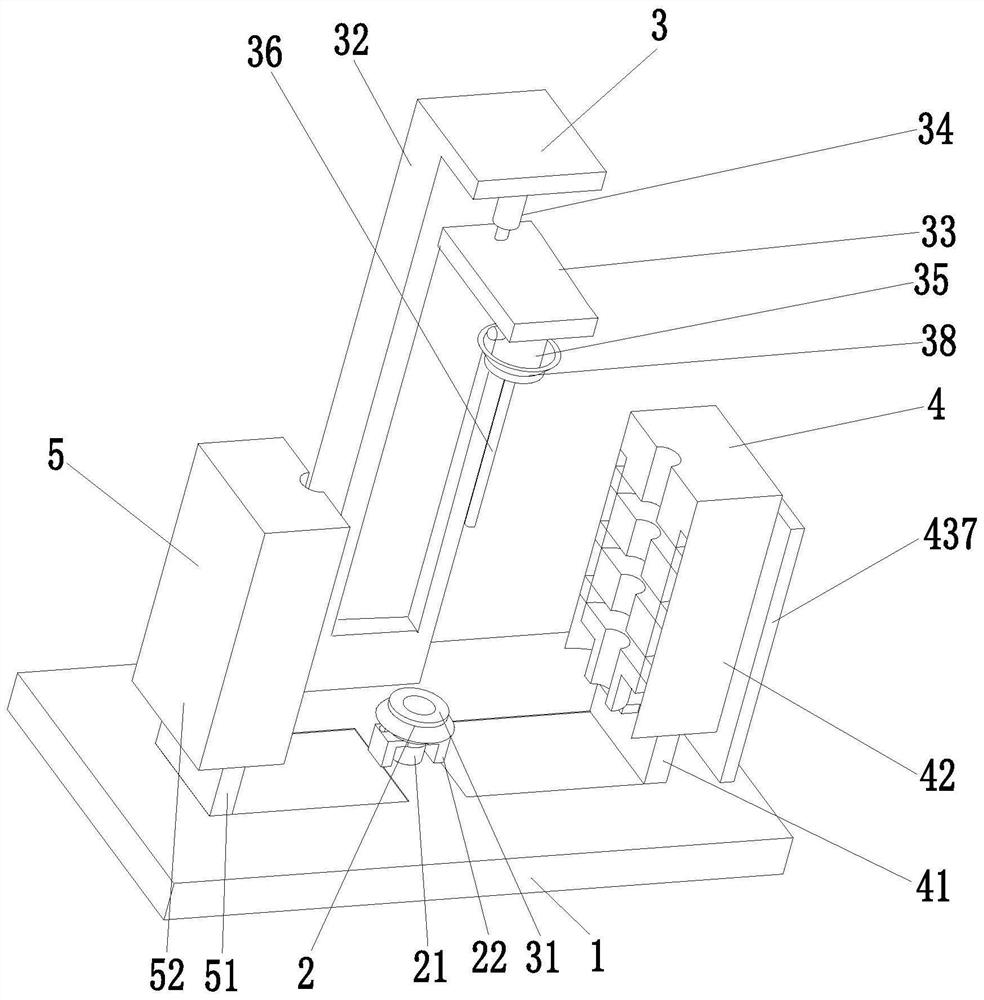

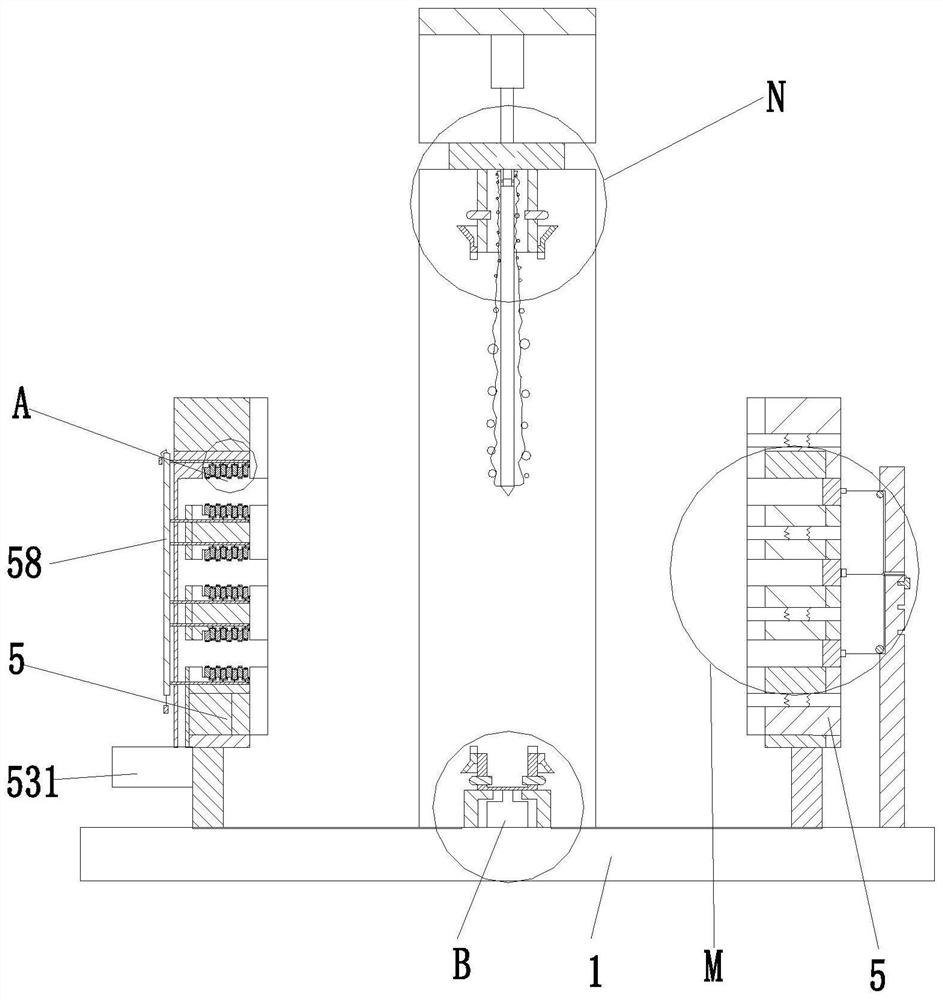

[0035]In order to make the technical means, the creation of the present invention, the purpose and energy is easy to understand, the following combinationsFigure 1 to 11Further, the invention is further illustrated.

[0036]A power insulator surface treatment system includes a bottom plate 1, a rotating mechanism 2, a fixing mechanism 3, a grinding mechanism 4, and a cleaning mechanism 5, and a cleaning mechanism 5 is mounted on the upper left side of the bottom plate 1. The upper end right side of the bottom plate 1 is mounted. 4

[0037]The rotating mechanism 2 includes a rotating motor 21 and an L-type support plate 22, and a rotating motor 21 is mounted in the upper end of the bottom plate 1, and two groups of L-type support plates 22 are mounted on the upper end of the rotating motor 21;

[0038]The fixing mechanism 3 includes a lower fixing tube 31, a L-type connecting plate 32, a slide plate 33, a stretch cylinder 34, an upper fixtures 35, a fixing post 36, a gas pump 37, and a tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com