Real-time solution detection equipment and method

A real-time detection and solution technology, used in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve the problem that the detection instrument cannot measure the solution by high-temperature electrical processing, and achieve the effect of ensuring the production process and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

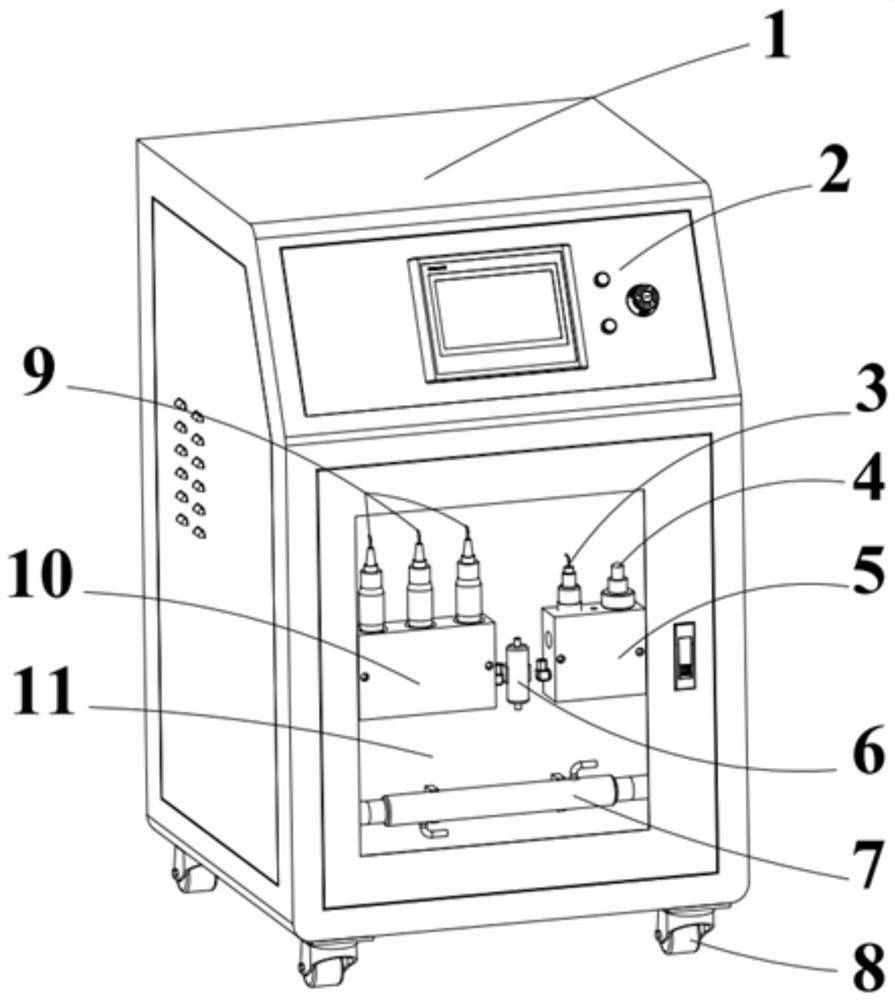

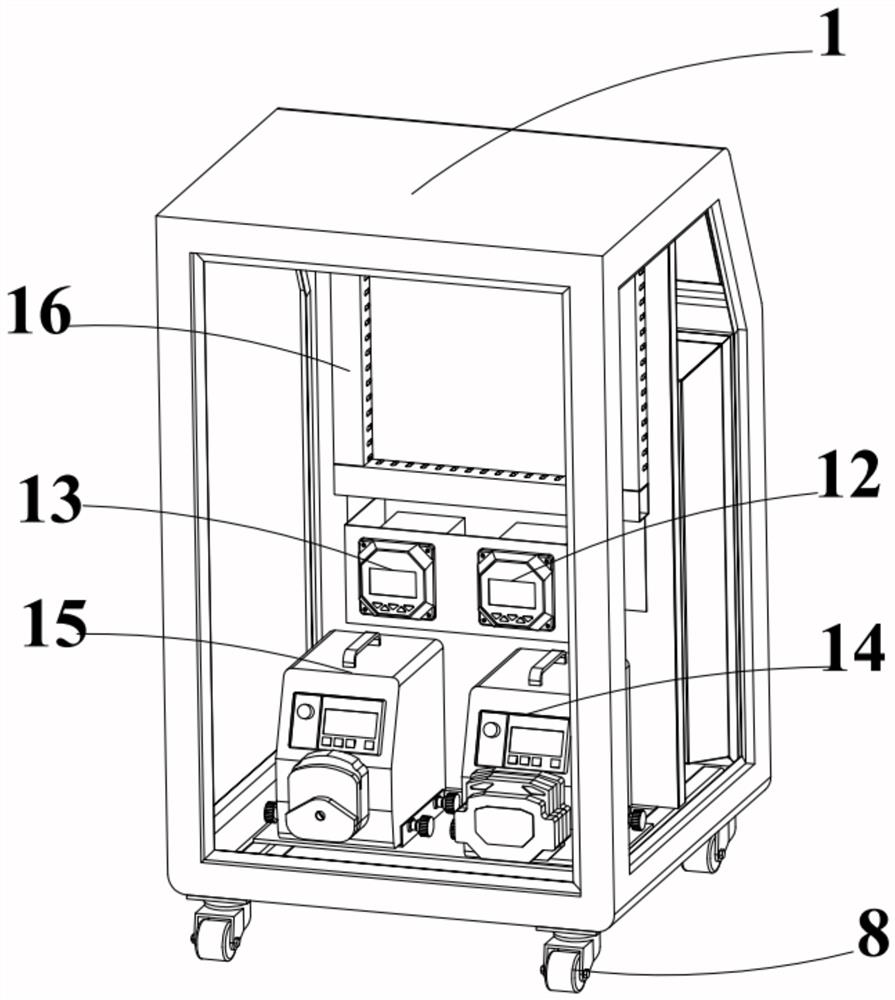

[0046] Embodiment 1, a solution real-time detection equipment.

[0047] as attached Figures 1 to 6 As shown, a solution real-time detection device of this embodiment is used for real-time detection of parameters of the electric processing solution in the electric processing system 102 or the solution at the outlet of the waste liquid treatment device, and includes a device casing 1, which forms a closed container chamber, a controller, a solution detection system 100, an infusion system 101, and a liquid return system 103 are arranged in the chamber, and a control panel 2 is embedded in the equipment shell 1, and the controller is electrically connected to the control panel 2, the solution detection system 100, and the infusion system 101 And the liquid return system 103, the input end of the infusion system 101 and the output end of the liquid return system 103 are externally connected to the water outlet of the electrical processing system 102 or the waste liquid treatment ...

Embodiment 2

[0067] Embodiment 2, a solution real-time detection method.

[0068] This embodiment provides a real-time solution detection method, which is applied to the solution real-time detection equipment described in Example 1, for real-time detection of the electromachining solution in the electrolyte plasma polishing system and after being treated by the waste liquid treatment device of waste liquid.

[0069] Wherein, the detection of the electromachining solution in the electromachining system specifically includes the following steps:

[0070] S11: Connect the input end of the infusion system 101 and the output end of the liquid return system 103 to an external electrical processing system to calibrate the pH, conductivity, and ion concentration sensors 9 (including concentration sensors for ammonium ions, chloride ions, and copper ions), After the calibration is correct, the pH and conductivity sensors 3 are installed in the first detection flow cell 5, and the ion concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com